cement test mill

TEXAS LEHIGH CEMENT COMPANY AccountSupport

TEXAS LEHIGH CEMENT COMPANY Box 610 Buda, Texas 78610 (512) LABORATORY TEST REPORT Spectrum's stucco product, Scratch Brown Coat, when mixed following the provisions of ASTM C 1328, yielded a material that substantially exceeded compliance with the applicable requirements....

Mountain Cement Company Sales Products Mountain Cement ...

Type III Portland Cement (low alkali, nonfalse setting) A general purpose cement used in construction of roads, home foundations, sidewalks, etc. Type II is used when moderate sulfate resistance is required. Click below for our latest Type III Certificate of Test. Type III (pdf) Type III LA (pdf)...

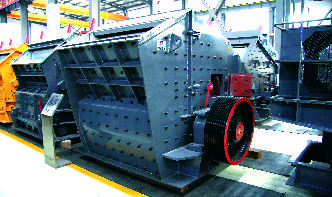

Laboratory Crushers, Pulverizers, Grinders | Laval Lab

Click here to discover our products. Laval Lab, the onestop specialist in Milling. For over 35 years Laval Lab Inc is the onestop specialist for size reduction of all types of materials....

Bond Work Index Procedure and Method

Cleaning and Storing of Ball Mill Charge after the Bond Work Index Procedure is done: Add about 500 g of silica sand into the mill containing the ball charge. Seal the mill. Rotate for 20 revolutions to clean. Empty the mill charge and sand into the ball try once grinding is complete. Clean out the mill using a brush. Put the lid on the mill....

IMPROVED CEMENT QUALITY AND GRINDING .

Improved Cement Quality and Grinding Efficiency by Means of Closed Mill Circuit Modeling. (December 2007) Gleb Gennadievich Mejeoumov,, Ivanovo State Power University, Russia;, Ivanovo State Power University, Russia Chair of Advisory Committee: Dr. Dan Zollinger Grinding of clinker is the last and most energyconsuming stage of the cement...

Ground Blastfurnace Slag What Is Mpa At Cement Grinding ...

what is mpa at cement grinding mill test is mainly used for grinding raw meal, clinker, Ground Granulated Blast Furnace Slag, iron ore, limestone, coal powder, coke powder, coal gangue, fly ash, volcanic ash, gypsum, calcite, pyrophyllite, quartz, clay, sandstone, bauxite and other processing industry related to metal and nonmetal mine....

Difference between Wet and Dry process of cement

Sep 10, 2018· The dry materials exiting the mill are called "kiln feed". Size of the kiln needed for manufacturing of cement is smaller. Difficult to control mixing of Raw materials, so it is difficult to obtain a better homogeneous material. Fuel consumption is low, 100 kg of coal per tonne of cement produced. Cost of production is less....

China High Quality Cement Test Mill (SM500)

Cement Test Mill, Mill, Cement Mill manufacturer / supplier in China, offering China High Quality Cement Test Mill (SM500), TBTTSR1 Retro Reflection Meter For Traffic Signs, TBTTSR1 Retro reflectometer For Traffic Signs and so on....

Effects of Adding Boron Compounds to Glycol Based Grinding ...

All produced cement samples were tested for Blaine fineness, xrf elemental analysis and 2, 7 and 28 days compressive strength tests. Test results of grinding aids of MEG and boron compounds mixture showed no increase in any age of compressive strengths performances related to MEG used itself....

cement test mill hs code

cement test mill hs code. Kuwait, Procedure, TIR Tuv cement test mill hs code,Sep 28, 2012 scope for the certification program, based on safety test reports Kneaders, Food Processors, Mills, Grinders, Blenders, Mixers, Juicers, Beaters Harmonized System Commodity Cod VI03 Cement 252321 / 252329Tariff Concessions 8479 to ......

types of cement mill

cement mills equipped for different types of products and depending on each cement mill size limitation. In each cement mill system, there is a separator fan, mill. Get Price...

lafarge pakistan cement mill test reports

cement test mill in pakistan lafarge pakistan cement mill test report. cement manufacturingtestfood components of a cement plant from quarry to kiln to cement mill. A world leader in . Cement mill Wikipedia. A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the ......

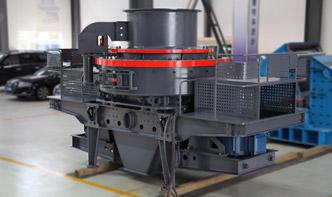

Cement MillCement Mill Price Mining Machinery

The cement mill is the key equipment for regrinding cement clinker after pregrinding by system ingredients. It plays a vital role in the cement production line and cement production process. Cement mills are mainly used in cement, silicate products, new building materials, refractory materials, glass ceramics, and other production industries....

Various Lab Test On Cement Civil Engineering

Various Lab Test On Cement Posted in Material Testing | Email This Post | Checking of materials is an essential part of civil engineering as the life of structure is dependent on the quality of material are the tests to be conducted to judge the quality of cement....

Welcome to Skyway Cement Company

S kyway Cement Company produces Slag cement, which is a valued construction material due to its superior performance and environmental qualities. Skyway's manufacturing facility is located in southeast Chicago near the Skyway Bridge. Skyway Cement is used in a wide variety of commercial and architectural concrete construction applications which include castin place, precast, bridges, ....

Cement Mill Drives Galbiati Group

Home Gear Reducers Cement Mill Drives Galbiati Group designs and manufactures main and auxiliary gear drives for mills and kilns with rigid electrowelded housings; carburized and quality DIN 6 profile ground teeth; high quality roller type bearings sized for at least hours fullload service; splash or forcedfeed lubrication....

White Cement Grinding Process Cement Mill Manufacturer ...

Cement mill features: With particular combined plate and discharging plate that adjust each silo position, air flow is increased and grinding condition is also improved; and new type lining plate is used and the speed of the cement ball mill is adjusted to optimize the design of gear; improve the stability of the cement tube mill; prolong the life expectancy of tube ball mill and improve the grinding efficiency....

Cement Board Construction

Aggregated portland cement core resists water penetration and w ill not deteriorate when wet. DUROCK Brand Cement Board is a superior substrate for ceramic tile, slate and quarry tile on all interior surfaces. Panels are manufactured in three widths for minimum cutting and easy handling and insta llation....

PROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL .

The mill is designed to handle a total ball charge of t at loading with a percentage filling of % in both the chambers. Both the chambers of the cement mill were charged with 80% of the designed charge, which works out to 86 t in Ist chamber and 172 t in the IInd chamber....

The Shepherdstown Cement Mill – Jefferson County Historic ...

The cement mill complex is on the south bank of the Potomac River in Jefferson County, West ia, approximately one mile east of Shepherdstown on River Road. The site contains the stone foundations of the mill, the kilns, the exterior walls of the warehouse, and the river wall....

cement test mill hs code

Part of Machinery, plant or .... country of origin of the cement based on the country of origin of at least 50% .... fall under the same tariff heading ( 4 digit HS Code). Chat Now Chapter 84 Central Board of Excise and Customs...

Cement hydration

Hydration products. The products of the reaction between cement and water are termed "hydration products." In concrete (or mortar or other cementitious materials) there are typically four main types: Calcium silicate hydrate: this is the main reaction product and is the main source of concrete strength. It is often abbreviated, using cement chemists' notation, to "CSH," the dashes indicating ......

definition for cement mill in electric drives

Cement mill Wikipedia. A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement is currently ground in ball mills and also vertical ....

What is the Material Test Report (MTR)/ Mill Test Report?

Material test report or Mill test report certifies that the chemical analysis and mechanical properties are in conformance with the specified specification. An MTR certifies a material's compliance with the standard specification such as ASME Section II Part A and B or ASTM....

(PDF) A comparison of wear rates of ball mill grinding media

The Ball Mill Abrasion (BMA) test was developed by the University of Queensland Materials Performance group to simulate the high stress abrasion conditions experienced in production ball mills....