operating principle of vertical stirred mill

How Does a Hammer Mill Work?

Sep 23, 2014· Hammer mills work in the principle that most materials will crush, shatter, or pulverize upon impact. 4. The Process: Material is fed into the mill grinding chamber through the feed chute, typically by gravity....

Roller Mill Maintenance00

Roller Mill Maintenance Roller mills are used around the feed mill to perform a variety of tasks. Applications include crumbling pellets, cracking corn, dry rolling and steam flaking grain, and grinding corn, wheat, or milo for mash and pelleted feeds. While each application has some unique...

stirred ball mill Mine Equipments

Grinding Ball Mill For Sale Grinding ball mill is a vertical stirred ball mill spiral for processing fine grade abrasive minerals. It abrasion treatment of the spindle blades, a blade at the bottom ......

Cement grinding Vertical roller mills versus ball mills

applications of the vertical roller mill for cement grinding are less prevalent. The twocompartment ball mill operating in a closed circuit with a high efficiency separator is thus still the most preferred arrangement for new cement grinding installations although the vertical roller mill now has emerged as a viable alternative...

operation principle of vertical grinding mill

operation principle of vertical grinding mill Vertical roller mill Wikipedia Vertical roller mill is a type of grinder used to grind materials into extremely fine powder for use in ....

stirred media grinding mills

TECHNOLOGY SELECTION OF STIRRED MILLS FOR ENERGY . Operating principle fluidized media stirred mills In contrast to the gravity induced stirred mills, the fluidized mill type uses high rotational speeds of either impellers or discs to cause the suspension and complete mixing of the grinding media and slurry particles....

operation of a vertical sand mill

working principle of vertical sand mill . Working Principle Of Vertical Sand Mill Bugs in your bead mill All smallmedia mills work on this principle, that if only a small mass is needed, and that many points of contact can be Most of the original Ball mill Wikipedia A ball mill is a type of grinder used to grind and blend, Working In case of, A rock tumbler functions on the ......

operational factory ball mill

Wholesale ball mill operating principle buy latest ball mill operating principle direct from 6890 ball mill operating principle Factories. ... which is a stirredball mill for grinding small amounts of chocolate liquor and refining small batches of chocola. ... vertical cement mill the operational It is an energy efficient alternative for a ......

Recent Advances in Power Requirement and Powder .

In this paper, recent results of tests in vertical stirred media mills with media, limestone and ynria stabilized zirconia in our laboratory are given. Mill dynamics, operating performance and physicochemical aspects in stirred media mills are also discussed. MILL,1ICS...

vertical mill operating principle

Vertical Roller Mill,Working Principle Of Vertical Roller Mill A vertical roller mill is a type of industrial equipment used to crush or grind materials into small particles. These machines consist of a large, heavyduty steel drum that relies on both hydraulic and pneumatic forces to pulverize rock or stone....

Horizontal Milling, Vertical Milling – What is a Milling ...

Generally, there are only two categories of milling machines which are the vertical mills and the horizontal mills. The vertical mills have a vertical orientation of the spindle axis, while the horizontal mills employ a horizontal orientation of the spindle axis. Vertical Mills. There are two popular types of ....

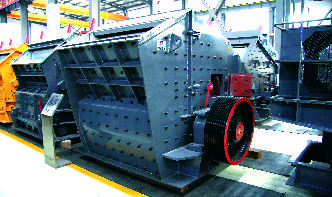

Hammer Mill: components, operating principles, types, uses ...

Hammer mills consist of a series of hammers (usually four or more) hinged on a central shaft and enclosed within a rigid metal case. It produces size reduction by impact. The materials to be milled are struck by these rectangular pieces of hardened steel (ganged hammer) which rotates at high speed inside the chamber....

The Working Principle of Milling Machines UK Essays

The working principle, employed in the metal removing operation on a milling machine, is that the work has rigidly clamped on the board of the machine, or held between centers, and revolving multiteeth cutter mounted moreover on a spindle or an arbor....

WORKING PRINCIPLE AND TYPES OF MILLING MACHINE ...

Jan 31, 2016· Working Principle of Milling machining operation Adjustable working table of milling machine will hold the workpiece and movement of adjustable working table will govern the feeding of workpiece against rotating milling cutter....

ball mill operating parameters of ball millxinhai global

The operating principle of the ball mill energosteel/en/the operating principle of the ball mill. The operating principle of the ball mill consists of following steps. In a continuously operating ball mill, feed material fed through the central hole one of the caps into the drum and moves therealong, being exposed by grinding media....

Mill (grinding) IPFS

This type of mill uses the same principle as VSI Crusher. Tower mill. Tower mills, often called vertical mills, stirred mills or regrind mills, are a more efficient means of grinding material at smaller particle sizes, and can be used after ball mills in a grinding process....

Stirred Mills – Ultrafine Grinding ScienceDirect

Vertical stirred mills are usually charged with media occupying 80% of the mill volume which is in sharp contrast to tumbling mills that are seldom charged more than 40% of their volumes to allow space for the tumbling action to develop. The stirred mills are charged with a media size of 10–12 mm and operated at a maximum tip speed of 3–8 m/s....

ball mill operating principle at paint manufacturing

Ball Mill: Operating principles, components, Uses, Advantages and. Jan 11, 2016 Ball Mill is a milling machine that consists of a hallow cylinder containing balls. They differ to an extent in their operating principle. The maximum capacity Ball mills are used for milling ores prior to manufacture of pharmaceutical ....