ore processing to make the gold purify

The Process of Making Gold Metacafe

Aug 08, 2008· **** How gold is produced, from excavation to ingotform. The Process of Making Gold Home Latest Popular Trending...

Gold Refining Buying Smelting and Assaying Refinery ...

Precious metal scrap such as placer gold, dental gold scrap and gold metal foil is weighed and then smelted. As the gold scrap liquefies in the furnace, borax and soda ash are mixed in to separate the pure gold from other precious and nonprecious metals. A sample is removed for assaying, which is the process of measuring the gold content....

Gold Bar Stardew Valley Wiki

A Gold Bar is created by smelting 5 Gold Ore in a furnace with 1 coal for fuel, or by transmuting 2 Iron Bars into one Gold Bar. Smelting Gold Ore in a furnace takes 5 ingame hours. The "Transmute (Au)" recipe is earned at Mining Level 7....

Sulfide Ore Processing « TCB Metals and Refining

For companies with platinum group sulfide ore with valuable base metals of nickel, cobalt, etc their ores, TCB can remove the precious metals and companies can then send the processed tailings to the proper refiner. TCB allows company representatives to be present during processing at our facility....

Chapter 82 Metal Processing and Metal Working Industry

The gold extraction process consists of feeding finely ground ore into a leaching tub and filtering a solution of potassium or sodium cyanide through it. The silt is separated from the gold cyanide solutions by adding thickeners and by vacuum filtration....

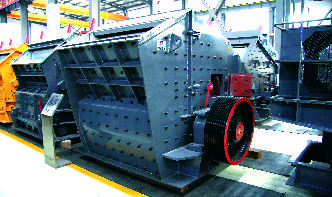

Galena Lead Ore Processing

The crude galena is crushed and screened to make galena granules dessociated from its gangue. Gravity separators like jigging machines can be used to purify lead ore. Machines like crushers, rod mills, jig separators, shaking tables can be involved in lead gravity processing line....

Extracting gold from rock OpenLearn Open University

Extracting gold from rock ... In some cinnabar ores, where the mercury sulfide concentration is high, you can actually see small beads of metallic mercury in the ore. It certainly wasn't the case with our cinnabar, unfortunately. ... The next step in the process is to separate the gold amalgam from any 'unreacted' mercury. We did this by ......

Environmental Geology Ch 13. Mineral and Rock as a ...

Processing generally involves finely crushing or grinding the ore. The fine waste (tailings) end up heaped around the processing plant to weather and wash away, much like spoil banks. Traces of the ore are left behind. Rapid weathing of the tailings may ....

Purest Gold: God's Refining Fire in our Lives

Many times in the recent past, I have been complimented on my purity, my desire to share the workings of our God through my life. These comments, like apples of gold in settings of silver, have been an encouragement to withstand the trials of God's refinement. Haggai 2:89 (8): The silver is mine, and the gold is mine, says the Lord of hosts....

copper extraction and purification

This page looks at the extraction of copper from its ores, its purification by electrolysis, and some of its uses. Before you get too bogged down in the extraction of copper, make sure that you need it for whatever syllabus you are using. Extracting copper from its ores. The method used to extract copper from its ores depends on the nature of ......

Uses of Gold in Industry, Medicine, Computers, Electronics ...

Uses of Gold in Electronics. Gold is the highly efficient conductor that can carry these tiny currents and remain free of corrosion. Electronic components made with gold are highly reliable. Gold is used in connectors, switch and relay contacts, soldered joints, connecting wires and connection strips....

How to Refine Gold in the Fire | eHow

There are two main sources for gold: mining and scrap. As gold prices go up, gold recycling becomes more attractive. But different pieces of recycled gold vary in the amount of gold they actually contain. Gold can be mixed with other metals like copper, which is used in ....

Testing the purity of the gold Gold Jewelry

Testing the purity of the gold. There are a few simple tests that you can make. Rub the piece of gold across a piece of unglazed porcelain tile. It should not make a black streak. If it does then it is the streak is golden yellow then it is gold. Try scratching glass with the piece of gold....

Gold Mining: Gold Mine Operations | World Gold Council

The gold mining operation stage represents the productive life of a mine, during which ore is extracted and processed into gold. Processing involves transforming rock and ore into a metallic alloy of substantial purity – known as doré – typically containing between 6090% gold....

How Much Cost To Purify Gold Ore

how much cost to purify gold ore galgotiasbschoolin 2010 The Cost of Gold Behind Gold s Glitter Torn Extracting copper mining extraction purification Get more . Gold mining Wikipedia. This type of gold mining is characterized by its low cost,, Gold ore processing, this is being achieved is via the promotion of socalled 'clean' or 'ethical ....

Turning Iron Ore into Iron Ingots? Stack Exchange

This is a spell that with 4 castings, converts two iron ore into two gold ore, which you can then smelt into one gold ignot, which can be combined with gems ....

purifying gold process

USA Process for refining and purifying gold . A process for purifying and refining gold to 98+% purity is dislosed. The gold to be refined is made the anode in an electrolytic cell with a solution of ammonium chloride as the electrolyte....

Metallurgic Processes | Boundless Chemistry

An ore is a type of rock that contains minerals with important elements such as metals. Ores are extracted through mining; they are then refined to extract the valuable element(s). The grade or concentration of an ore mineral, or metal, as well as its form of occurrence, will directly affect the costs associated with mining it....

How to Choose Gold Smelting Flux Superb Elctromachinery ...

It is the major part of refining where the precious metal (gold in this case) is melted out of its ore. Metal ores often contain a lot of other elements and impurities, smelting is therefore important in removing these. Gold smelting flux is often added to the ore during the smelting process....

How profitable is gold mining? Quora

May 01, 2017· A typical mining project yields between half a gram to 5 GPT, with the global average being less than 2 GPT. It also takes 24 to 48 hours to process that minable ore. For example, Barrick Gold and Newmont Mining must process thousands of tonnes of ore a day to preserve their top positions as the kings of gold producing. It's a huge operation, which is why their AISC are ....

Iron Ore Processing for the Blast Furnace

blast furnace process. The iron ore concentrate is now mixed and ready for the pelletizing process. Pelletizing A pellet plant contains a series of balling drums where the iron ore concentrate is formed into soft pellets, in much the same manner that one rolls a snowball, to make a pellet about the size of a marble (between 1/4" and 1/2")....

Better to sell raw material or refine than sell? — Elder ...

Jan 08, 2017· Usually, this puts unrefined rubedite ore at 22k a stack. If you refine them, you'll likely get less than 200 ingot, a 5% chance at getting a gold temper, and a bunch of other misc. items that may or may not have any value....