rotor for an impact crusher

B Series Deep Rotor Vertical Shaft Impact Crusher

B Series Deep Rotor VSI Crusher is a new generation and high effective product which introduces German technology, and owns many independent patent properties. It integrates three crushing methods into one. All of these made it the core equipment in sand making industries....

rotor for vertical shaft impact crusher

An impact crusher can be further classified as Horizontal impact crusher (HSI) and vertical shaft impact crusher (VSI) based on the type of arrangement of the impact rotor and shaft. Horizontal shaft impact crusher These break rock by impacting the rock with hammers/blow bars that are fixed upon the outer edge of a spinning rotor....

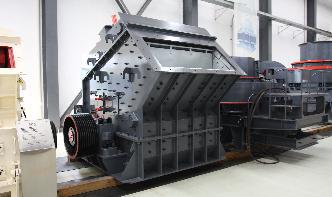

Horizontal shaft impact (HSI) crushers

SelfRotor Rotation system (SRR) is available for all ® NP Series™ HSI crushers. It allows positioning the rotor during the maintenance period when changing the blow bars or adjusting the breaker plates without human intervention inside the crusher....

New Used Impact Crushers for Sale | Rock Crushing ...

New and Used Impact Crushers for Sale Savona Equipment is an impact crusher supplier crusher is designed to work with a certain maximum size of raw material, and often delivers its output to a screening machine which sorts and directs the product for further processing....

Keestrack R3 Mobile tracked Impact crusher

R3 Destroyer mobile tracked Impact crusher with a capacity of 250 tonnes an hour. Applications limestone and many other low and medium abbrasive natural rock, concrete and landfill recycling, primary and secondary crushing, yard clean up, construction waste, demolition, quarrying and mining, gravel, asphalt, coal and other...

XF Series Impact Crusher

The unique design of heavyduty rotor, involute crushing chamber, heavy crushing plate, wearresistant hammer head and hydraulic opening device ensures that it has the characteristics of large crushing capacity, stable product quality, low production cost and convenient operation and maintenance....

Torgerson Impact Crusher | Heavy Equipment Forums

Jul 14, 2018· Apparently Lee Torgerson did design, build and sell impact crushers. There were a few models apparently following the XX designation, AXX, BXX, CXX and so on. We are thinking this only refers to size. The rotor impact bars are still readily available from Spokane Industries....

Keestrack R3 | Impact Crushers | Equip2

Keestrack R3 Impact Crusher The Keestrack R3 Impact Crusher is one of our most popular crushers; being easily transportable, compact, highly productive and costeffective. It features the largest rotor is it's class, along with defining features like an integrated prescreen, load sensing hydraulics and closed circuit afterscreen....

rotor for impact crusher or hammer mills

Impact Crushers Cement Crushers Rotor Impact Crusher . What is an Impact Crusher? Impact size reduction incorporates striking to pulverize material. The primary types of impact crushers include horizontal shaft impactors (HSI), cage mill pulverizers, and vertical shaft impactors (VSI)....

R I140 Impact Crusher TransDiesel Ltd

Rotor fitted with 2 full ceramic blow bars to rotor Rotor fited with 2 full high chrome blow bars to rotor Rotor fitted with 4 full martensitic blow bars to rotor Rotor fitted with 4 full ceramic blow bars to rotor Rotor fitted with 4 full high chrome blow bars to rotor Independent prescreen c/w extended bypass conveyor with 650mm...

Types of Crushers Mineral Processing Metallurgy

Impact Crushers: This division is represented chiefly by the various styles of hammermill; also by the cage type disintegrator. Combination Impact and Sledging Crushers. In this class we have the single or double sledging roll crushers. An example of the former is the Fairmount crusher, of the latter, the Edison roll crusher....

DESIGN AND ANALYSIS OF A HORIZONTAL SHAFT .

An impact crusher can be further classified as Horizontal impact crusher (HSI) and vertical shaft impact crusher (VSI) based on the type of arrangement of the impact rotor and shaft. Horizontal shaft impact crusher These break rock by impacting the rock with hammers/blow bars that are fixed upon the outer edge of a spinning rotor....

Impact Crushers |

Advances in impact crusher technology include fully or semiautogenous breakage systems, and improvements in rotor design and metallurgy for steelonsteel systems. We offer both Horizontal Shaft Impactors (HSI) and Vertical Shaft Impactors (VSI) to suit your application needs....

What Is A Vertical Shaft Impactor (VSI) Primer? | Stedman ...

When it comes to producing materials such as aggregate for road making, VSI crushers use a highspeed rotor and anvils for impact crushing rather than compression force for the energy needed for size reduction. In a VSI, material is accelerated by centrifugal force by a rotor against the outer anvil ring, it then fractures and breaks along natural faults throughout the rock or minerals....

Eagle Impact Crusher Rotor Parts

eagle impact crusher rotor parts crusher eagle conecrusher, Basalt Related Product Information rotor mill type ultra fin; ultra max 25 crusher parts | worldcrushers eagle ultra max impact crusher basalt, eagle impactor spare parts Cone Crusher,Crushers For Sale Equipment Trader 154 results AUSTINWESTERN, 32x40 Aggregate ....

PF Impact Crusher

The wear parts have hammer, impact plate and side liner plate, and so on. Working Principle. The rotor does the highspeed rotation under the driving of a motor. The material impacts with the hammer on the rotor. Then, under the hitting of hammer, the material is broken. The crushed material is impacted to the impact plate and broken again....

VSI Crusher Vertical Shaft Impactor

In a vertical shaft impact crusher, the aggregate feed is introduced into a shoe or pump spinning on a vertical axis. The aggregate feed is thrown centrifugalLY against a series of anvils, pockets of aggregate particles (, autogenous), or a combination thereof....

Dual Single Rotor Crushers | MPDInc

Single Rotor Crusher Single rotors crushers are often used for high load applications or where a specific custom rotor is needed. Single Drum Rotor Crusher Single Drum Crushers are often used in a flooded state application to break down your product to ....

Impact Crusher VS Hammer Crusher JXSCMINE

The impact crusher machine can conveniently adjust the discharging particle size and in a wide range. The impact rock crusher can adjust the discharging particle size in many ways. Such as adjusting the rotor speed, adjusting the clearance between the impact plate and the Hammer, etc....

Stone Crusher,Rock Crusher,Mining Equipment ...

Mobile impact crusher. This DMP series mobile impact crusher is a kind of high efficiency mobile crushing station, which is research and development by (zhengz. more; Stone crusher hammer. Hammer crusher, precise definition should be hammer crusher hammer, hammer is one of the core components hammer crusher, crusher arranged on . more...

The rise of mobile impact crushers for recycling ...

The impact crusher is a first and secondstage crusher in one unit, so you can crush a 600mm product down to a final product for resale as recycling aggregate. "Our machines are excellent in recycling asphalt, as we can slow down the rotor speed to crush the asphalt, but not the aggregate inside the asphalt, so the material can be reused in ......

Secondary Impact Crusher | Willpactor II® | Williams Crusher

Superior Rotor Design. The Willpactor II Secondary Impact Crusher rotor is contoured and computer designed for maximum efficiecy. The rotor's features include: Proven, positive breaker bar holding devices with buried wedges to provide minimized wear as ....