calcium carbonate plant process

Understanding and Correcting Soil Acidity Noble Foundation

Lime or calcium carbonate's reaction with an acidic soil is described in figure 1, which shows acidity (H) on the surface of the soil particles. As lime dissolves in the soil, calcium (Ca) moves to the surface of soil particles, replacing the acidity. The acidity reacts with the carbonate (CO 3) to form carbon dioxide (CO 2) and water (H 2 O ......

What is the difference between calcium carbonate and ...

Sep 25, 2016· Precipitated calcium carbonate is generally whiter (hence used in paper manufacture) and because it is a process, the crystal size (and to some extent the crystal type) can be controlled by adjusting the process conditions. It is of course more expensive than the mineral....

Nuclear Plant Efficiently Removes Calcium Carbonate From ...

Calcium carbonate scale, however, poses a serious problem that, until recently, defied standard removal procedures. It is a crystalline compound found in such materials as limestone and marble....

Calcium Carbonate | pulp paper mill

Jan 01, 2013· Calcium Carbonate. Ground calcium carbonate (GCC) Ground calcium carbonate is manufactured by grinding limestone or marble because of their high brightness and purity. Generally the particle shape of ground calcium carbonate is rhombohedral. This filler material is used in alkaline wood free papermaking process....

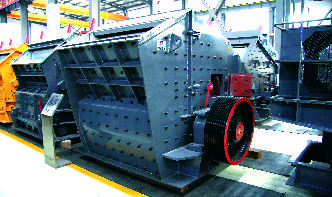

Calcium Carbonate Manufacturing Plant

Calcium Carbonate Manufacturing Plant Crushing plant for calcite provides smooth processing process and is handled by competent workforce. We develop calcite crusher in stationary, portable, mobile series to meet the different calcite manufacturing demands....

calcium carbonate processing plant flow chart

It is often seen in quarrying plant, ore beneficiation plant and power station and it is a important ... detailed flow chart explaining the mining and processing of magnesite, You Can Buy detailed ... calcium carbonate mining process flow chart....

Welcome to Calera

The unique calcium carbonate cement made in the Calera process can be used without any other cement or binder system to make concrete products. Calera demonstrated the ability to make a variety of decorative concrete products such as countertops, plant holders and benches. The products contain traditional sand and aggregate all held together in......

process flow of precipitated calcium carbonate plant

Precipitated calciumcarbonateplant: The Precipitated Calcium Carbonate Plant offered by us is made by following steps: Calcination / Burning of limestone in a vertical shaft lime kiln to give quick lime and carbon dioxide gas....

Standard Process Calcium Lactate Supplement | Standard ...

Since 1929, Standard Process has been the visionary leader in whole food nutrient solutions. We apply systems thinking to holistic nutrition that empowers practitioners to transform lives. Dedicated to the whole food philosophy of our founder, Dr. Royal Lee, our goal is to carry on his mission to provide nutrients for the body that are as close ......

Cement from CO2: A Concrete Cure for Global Warming ...

Aug 07, 2008· The Calera process essentially mimics marine cement, which is produced by coral when making their shells and reefs, taking the calcium and magnesium in seawater and using it ....

Calcium carbonate processing plant Calcium carbonate ...

Penta Process is a team of engineers with many years of experience in the fields of Process Design, Mineral Processing, fingernägel aufkleben dm Automation and Project Management. Early homogenous amorphous precursor stages of calcium carbonate and subsequent crystal growth in levitated droplets SE Wolf, J Leiterer, M Kappl, F Emmerling, W ......

Calcium Foliar Spray Making Calcium Spray For Plants

Calcium foliar spray lends necessary calcium to the plant, preventing leaf necrosis, short brown roots, fungal issues, weak stems and stunted growth (damping off). Making calcium spray for plants will increase cell division, an important component, especially in those rapid growers such as tomatoes, sweet potatoes, and corn....

Calcium Carbonate NETZSCH Grinding Dispersing

Calcium Carbonate Calcium carbonate (CaCO 3 ), which occurs primarily in the form of the minerals calcite and aragonite, is one of the most prevalent compounds on Earth. Calcium carbonate is not only the main component of marble, limestone and dolomite, it is also found in bones and teeth as well as the exoskeleton of crustaceans, coral, muscles, snails and protozoa....

calcium carbonate processing plant Solutions ...

Calcium Carbonate Ore Processing Flow. Calcium carbonate process . Ore Processing Grinding Plant Calcium Carbonate Process. Calcium carbonate is a . What is the process through which calcium carbonate forms . Calcium carbonate is the most common organic compoundand raw material found on the surface of Earth. It carries the chemical formula CaCO3....

4. EFFECT OF GYPSUM AND CALCIUM CARBONATE ON PLANTS .

iii. the total and active calcium carbonate contents iv. the availability of plant nutrients and moisture content in the root zone v. the type of crops grown and their relative tolerance to gypsum vi. the drainage conditions and salinity of the soil....

Calcium: A Central Regulator of Plant Growth and ...

Today no one questions the assertion that Ca2+ is a crucial regulator of growth and development in plants. The myriad processes in which this ion participates is large and growing and involves nearly all aspects of plant development (recent reviews in [Harper et al., 2004][1]; [Hetherington and...

CNB Process for producing trichloroisocyanuric ...

The invention relates to a production process for producing trichloroisocyanuric acid by using calcium carbonate as a raw material. The process is characterized in that: reactants comprise calcium carbonate, cyanuric acid, water and chlorine; and in the technical scheme, the chlorine and the water perform a hydrolysis reaction, and then the hydrolysate reacts with the calcium carbonate and the ......

What is Calcium Carbonate? Industrial Minerals ...

Calcium carbonate decomposes to form carbon dioxide and lime, an important material in making steel, glass, and paper. Because of its antacid properties, calcium carbonate is used in industrial settings to neutralize acidic conditions in both soil and water....

Integration of the calcium carbonate looping process into ...

Integration of the calcium carbonate looping process into an existing pulverized coalfired power plant for CO2 capture: Technoeconomic and environmental evaluation Article in Applied Energy 222 ......

Sodium Carbonate 100 lbs – CQ Concepts

Sodium carbonate is widely used in photographic processes as a pH regulator to maintain stable alkaline conditions necessary for the action of the majority of developing agents. Sodium carbonate is also used by the brick industry as a wetting agent to reduce the amount of ....

CORROSION CONTROL: Using Caustic Soda to Control .

Experience has shown that it is difficult to develop a uniform deposition of calcium carbonate throughout the distribution system. Deposition generally occurs close to the treatment plant and less protection is provided as the water travels further from the plant, typically where the lead and copper containing fixtures are located....

IMANA Calcium Carbonate Life Cycle Assessment

Depending on the particular grade of calcium carbonate, either t he plant processing and quarry operation stages of the products generally contribute the most to the cradletogate life cycle impacts. This is mainly due to the high electricity use in the plant processing stage and the explosives used in the quarry operations stage....

Researchers: Power Plant CarbonCapturing Calcium ...

Researchers: Power Plant CarbonCapturing Calcium Carbonate Looping Technology Almost MarketReady. The calcium carbonate then is transferred in the second of the two fluidized bed reactors, known as the regenerator, where high temperatures force out the CO 2 bound as the calcium carbonate thereby producing burnt lime and CO 2 once again,"......

Sodium Carbonate 100 lbs – CQ Concepts

In 1791, the French chemist Nicolas Leblanc patented a process for producing sodium carbonate from salt, sulfuric acid, limestone, and coal. First, sea salt (sodium chloride) was boiled in sulfuric acid to yield sodium sulfate and hydrogen chloride gas, according to the chemical equation...

How is the combustion process of calcium carbonate carried ...

Aug 18, 2016· Calcium carbonate doesn't combust when heated in air, it decomposes into calcium oxide and carbon dioxide; CaCO3(s) —> CaO(s) + CO2(g) The process is called calcination and is normally carried out in a kiln at temperatures of between 800 and 10......