ores process for magnetic separator

Dry Process Magnetic Separator – Electro Magnetic Industries

Dry Process Magnetic Separator is applied to recycle ores from barren rocks, or, to separate oresfrom rubbles for mines with intercalated bed. it is also used to recycle or remove iron materials. Structure: it consists of hopper, vibrating feeder, belt conveyor, rotary drum with strong magnetic force and separated ore hopper....

Magnetic Separation of Iron Ores by the Grondal Process ...

About twenty years ago the question of iron ore supplies became serious, and at that time magnetic separation received considerable attention from Conkling, Ball and Norton, and others, with the idea of utilizing large bodies of magnetic iron ore which could only be made available by means of magnetic ....

Hematite Magnetic, Magnetic Separation, Magnetic ...

Introduction. According to the magnetic difference of various ores or materials, the crude ore or materials realize the final mineral separation under the magnetic force and other mechanical on 20 years of mineral processing experience, Xinhai continuously develop and innovate magnetic separation process on the basis of the traditional magnetic separation technology, and ....

USA Dual intensity magnetic separation process ...

The use of conventional magnetic separators to remove ferromagnetic minerals is known. Magnetic separation is an important process that has been used in mineral dressing for many years. Most metallic ores are crushed and the values are concentrated using flotation, gravity settling, electrostatic separation, or other special processes....

IMPTEC's Dry Superfine CrusherMagnetic Separator Combo ...

Aug 18, 2017· IMPTEC's Dry Superfine CrusherMagnetic Separator Combo Wins Best Processing Paper at Iron Ore 2017 Published on August 18, 2017 August 18, 2017 • 49 Likes • 21 Comments...

PROCESS AND APPARATUS FOR SEPARATION OF MINERAL ORE .

May 21, 1974· Thus, magnetic separation processes which require dry particles, which in turn require heating of the particles to dry the same, will be unsuitable for the separation of the magnetite crystals from black sands containing rutile and ilmenite. Wet magnetic separators have also been employed to separate particulate ferromagnetic mineral ores....

Roasting Followed by Magnetic Separation: A Process for ...

Roasting Followed by Magnetic Separation: A Process for Beneficiation of TitanoMagnetite Ore M. S. Jena CSIRInstitute of Minerals Materials Technology, Bhubaneswar, India Correspondence msjena...

MAGNETIC SEPARATORS

Examples of application of magnetic separators in various fi elds Removal of iron and collection of iron powder from various kinds of raw materials and semifi nished products are called magnetic separation. Kanetec off ers a wide variety of magnetic separators for use with lump materials, bulk materials, claylike materials and liquids....

how is the magnetic ore separator

Magnetic Ore Separator 911metallurgist After considerable experience in connection with the magnetic ironores at the South, especially in the Cranberry district of western North Carolina and eastern Tennessee, the writer was led into a thorough investigation of the magnetic separation of ironores, and, from this investigation, has ......

Concentration Iron Ore Magnetic Separation

iron ore magnetic separation with large capacity in somalia. Iron ore magnetic separation metallurgist. apr 20 the concentration of lowgrade magnetic iron ores separating the magnetite largescale operations and the liberal expenditure of enough money at of the ballnorton separator and greatly increases the capacity and....

Process separator All industrial manufacturers Videos

highgradient magnetic separator / quartz sand / process / for ore DLS Series. Make a request. highgradient magnetic separator. DLS Series. Width: 3 m ... DMD is a rotating discs magnetic separators for coolants used during industrial machining contaminated by magnetic particles. For flowrates over 600l/min of emulsion and 300l/min of neat oil ......

permanent drum magnetic separator for iron ore process

Wet Drum Permanent Separators | Magnetic Separation... ores. Wet drum separators work on a similar principle to our other existing drum ... Used for the recovery of magnetic / ferrosilicon in dense media plants and iron ores. ... a clean magnetic product completing the magnetic separation process....

magnetic separation process of iron ore

Magnetic separation process The magnetic separation process, also named the magnetic separating production line and made up of jaw crusher, ball mill, classifier, magnetic separating equipment, concentrator and dryer, is a wet and dry separation combination method of magnetite....

CHAPTER8 BENEFICIATION OF IRON ORES

MAGNETIC SEPARATION PRINCIPLES AND APPLICATION IN BENEFICIATION OF IRON ORES A. Das and S. Roy INTRODUCTION Magnetic Separation is one of the physical concentration processes that utilizes the differences in magnetic properties of various minerals present in the ore body. The...

magnetic separation process of iron ore

Dry Magnetic Separation of Iron Ore of the. An implementation of twostep concentration (afterpurification) allowed increasing the iron content in the concentrate up to %. It forces to upgrade the process of dry magnetic separation or carry it out in the liquid phase (socalled, wet separation). Fig. 5 shows the iron ore after the process ......

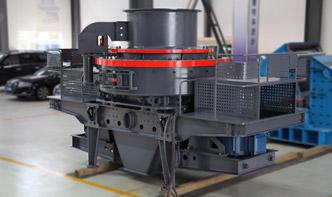

dry magnetic separator tin ore – Crusher Machine For Sale

Crusher Machine For Sale. ... dry magnetic separator tin ore manufacturer in Shanghai, China. ... Ore processcrushing plant and mill for mineral ores beneficiation . Ore process is most used crushing plant, grinding mill and ores beneficiation equipment for manufacturing. Those ore processing plant is most like jaw crusher, ball ....

iron ore magnetic separation process

magnetic separation process of iron ore Magnetic separator is the professional refinement and iron removal equipment that can be used in the magnetic iron ore the dressing process such as magnetite, hematite, magnetic pyrite and limonite and nonmetallic materials iron removal working including coal, quartz and gypsum. ......

nickel ore mining process magnetic separation

magnetic separation for nickel low noise; desorption electrolysis system for nickel mini; brand nickel ore flotation machine with ce; magnetic separator for nickel mini; small nickel processing plant; wear resistant rubber slurry pump for nickel high quality; mining methods for nickel ore; continuous row of high efficiency concentrator for ......

magnetic separation Archives International Mining

The magnetic separator is used in a process to extract primarily tantalum from coltan, which is a combination of columbite and tantalite. For this new project, tests were undertaken in the Master Magnet test facility in Redditch, England. The tests confirmed the level of separation, capacity and the magnetic separator configuration....

Magnetic separation process

Magnetic separation process. The magnetic separation process, also named the magnetic separating production line and made up of jaw crusher, ball mill, classifier, magnetic separating equipment, concentrator and dryer, is a wet and dry separation combination method of magnetite....

Dry Magnetic Separation Of Iron Ore Process

Hematite Iron Dry Magnetic Separator . Hematite Iron Dry Magnetic Separator Similar to limonite iron ore, hematite is kind of weak magnetic iron ore with the similar beneficiation methodgravity separation, intensity magnetic separation, magnetizing roasting process during which the most common beneficiation way is gravity separation....

magnetic separator iron ore crushing plant

Magnetic plant or magnetic separation process is mainly used for separation of magnetic minerals, which includes dry and wet magnetic separation process. The equipment used in iron ore magnetic separation plant mainly includes crusher, vibrating screen, ball mill, classifier, magnetic separator, tailings recovery machine, etc....

We Mining Equipment,Magnetic Separation Process,Ore ...

Magnetic Separation ProcessThis new type environmentally friendly magnetic separation process combines dry separation method and wet separation method. The process separate powdered ore to three classes and after that, the wet magnetic separation uses magnetic density of 400~1200GS. The magnetic drum rotation speed is 60~320 rpm....

iron ore magnetic separator grinding ball mill

Manganese ore belongs to the weak magnetic minerals, which can be recovered by highintensity magnetic. Kaolin Mining Process Dry And wet separation are the two main Kaolin mining process of ....