mining method of graphite

Environmental Risks of Mining Massachusetts Institute of ...

Mining is an inherently invasive process that can cause damage to a landscape in an area much larger than the mining site itself. The effects of this damage can continue years after a mine has shut down, including the addition to greenhouse gasses, death of flora and fauna, and erosion of land and habitat....

Standard Test Method for Determination of Lead in ...

The flame atomic absorption method is applicable to the determination of masses of approximately 1 to 200 μg of lead per sample, without dilution (1). 2 The graphite furnace atomic absorption method is applicable to the determination of masses of approximately to μg of lead per sample, without dilution (1)....

Could graphene batteries change the face of graphite ...

As the world turns to batteries, mining operations will have to expand to meet demand; currently the biggest graphite mine in North America produces just 25,000 tonnes annually. While synthetic graphite can be altered for use in battery technologies, the large amounts of coal required to produce it dramatically reduces its green credentials....

What are the processing methods of graphite

We also often recover silver as a byproduct of lead processing. It is graphite that is used in pencils, and the mineral graphite is an allotrope of carbon....

Green Mining Massachusetts Institute of Technology

Two major methods of implementing green mining reform are governmental regulation and innovative technologies. Better regulation generally precedes cleaner mining practices. China's new regulations for their mines are a good example of ideal government intervention with regards to the specific ideas that the laws encode (enforcement has not been considered)....

Graphite Mining Stocks

Jul 25, 2012· Graphite prices tripled in short order: It was when the price for the commodity was rising that I started telling you to buy graphite mining stocks. And You Still Should Be. Whenever the price of a commodity rises as dramatically as it did with graphite, inevitably companies try to find more graphite to mine. Makes sense, right?...

Challenges Faced by Narrow Vein Graphite Mining and ...

Graphite mining at Bogala Mines, Sri Lanka is a unique example of narrow vein mining faced with numerous wall stability issues resulting from weak graphite infilled joints. The Bogala vein type graphite orebody has an average vein width of 1 m. Overhand cutandfill mining method is used for stoping....

method of mining graphite

abstractthis paper includes the study of the mining method adopted at bogala graphite mines and its sui ility compared with other mining methods used in nbsp. Is Graphite expensive to mine Answers. No, your pencillead is made out of graphite and pencils are cheap so mining graphite would be....

Graphite | Earth Sciences Museum | University of Waterloo

During the mideighteenth century, graphite first began to be mined by modern methods at Cesky Krumlov. Other Graphite Mines were formed nearby. The presence of lots of highly metamorphosed rocks such as gneisses were found along the two rivers known as the Danube and the Vitaca (which was called the Moldau in German)....

Graphite purification High temperature method .

At present, various methods of graphite purification at home and abroad, mainly flotation, alkali acid, hydrofluoric acid, chlorination roasting and high temperature purification methods, systematically expounded their basic principles, process conditions, research progress and In the actual production of the application of the advantages and disadvantages of various methods in comparison, the ......

benefication of natural flake graphite methods BINQ Mining

Graphite – Wikipedia, the free encyclopedia. There are three principal types of natural graphite, each occurring in different types of . Crystalline flake graphite (or flake graphite for short) occurs as isolated, flat, . 6 Graphite mining, beneficiation, and milling; 7 Graphite recycling; 8 See also ... In 1896 Acheson received a patent for his method of synthesizing graphite, ....

Open Pit Mining Techniques|Surface Mines|Rock or Mineral ...

Openpit mining, also known as opencast mining, opencut mining, and strip mining, means a process of digging out rock or minerals from the earth by their elimination from an open pit or borrow. The word is used to distinguish this type of mining from extractive methods that need tunneling into the ....

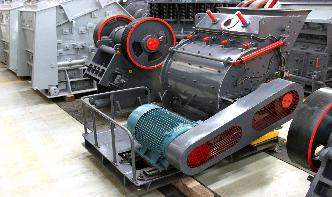

machinery used in graphite mining YouTube

Jul 01, 2019· Mason Graphite: Key Process Equipment Delivered for the ...Mason Graphite is a Canadian mining and processing company focused on the development of its owned Lac Guéret natural graphite deposit ......

Evaluation of Overhand Cut and Fill Mining Method usedin ...

This research includes the study of the mining method adopted at Bogala Graphite Mines and its suitability compared with other mining methods used in the mining industry. The mining method ....

Strategic Graphite A Survey USGS

Strategic graphite consists of certain grades of lump and flake graphite for which the United States is. largely or entirely dependent on sources abroad. Lump graphite of high purity, necessary in the manufacture of carbon brushes,...

Mineral Notes: Graphite | Snowden Group | Mining and ...

Amorphous graphite is mined underground, mainly in China, using methods similar to coal mining. The most commonly used beneficiation method for flake graphite is flotation, while acids or alkalis may be used to leach out impurities from concentrates....

(PDF) A Review of Graphite Beneficiation Techniques

A Review of Graphite Beneficiation Techniques. Graphite ore is mostly beneficiated using flotation separation techniques. The increasing demand for highgrade graphite products with up to % carbon has resulted in the development of various approaches ....

MACHINING GRAPHITE AND CARBON

Sawing graphite and carbon. . Grinding graphite and carbon. . Surface finishing graphite and carbon. General guidelines for machining graphite and car bon. Graphite is abrasive material causing fast wear of metallic uncoated cutting tools. Only diamond (preferable) or ....

Flotation of graphite ScienceDirect

Minerals Engineering, Vol. 4, Nos 711, pp. 975982, 1991 /91 + 000 Printed in Great Britain Pergamon Press plc FLOTATION OF GRAPHITE T. WAKAMATSUand Y. NUMATAI Dept. of Mineral Science and Technology, Faculty of Engineering, Kyoto University, Kyoto, Japan t Dept. of Mining Engineering, Faculty of Mining, Akita University, Akita, Japan ABSTRACT This paper ....

Graphite Processing,Flotation, Production Line | Prominer ...

The graphite concentrate is mixed with caustic reagent and calcined at elevated temperatures. After calcination the graphite is leached with water washing away dissolved impurities. In order to get ultrahigh purity graphite, the fine intergrown minerals residing between the graphite ....

Under Ground Mechanized Mining Methods

Under ground mechanized mining methods. Drop Raising in Mining (VCR) Methods of Stopes ( Extraction of Ore). Hindustan Copper Limited has addressed the complex 'raising' operation in mining and developed and implemented Drop Raising techniques at 80 meters intervals which improved safety and led to faster and higher productivity....

Mining, concentration and refining of American flake ...

6INTRODPCTION The Greisemer G'raphi te Company was ineorporated June 3, 1916, under the laws of Alabama, for the purpose of mining, milling and refining of flake graphite. ion was immediately be6Wl 0~1 the plant and it was Febrll:ary, 1917. After being in...

Graphite Advantages | Mersen USA | World leader in ...

Graphite used for EDM machining is an isotropic material with a grain size ranging from a few microns to about 20 microns. In the 1970's, improvements made by graphite manufacturers (isotropic properties, consistent quality, large size billets) combined with the emergence of EDM machines equipped with isoplus generators, allowed graphite to become the most commonly used material for EDM ....