make concrete mix machine

How to make stone, tile, pavers and bricks with concrete ...

ITEMS NEEDED TO MAKE OLDE WORLD CONCRETE STONE: FiveGallon Plastic Bucket, Wheel Barrow, or Concrete Mixing Tub Bags of Premix Concrete Concrete Colorant Water Shovel Plastic Wrap Molds Plastic Gloves and Eye Protection Mold Release Concrete Sealer. THE DIFFERENCE BETWEEN CONCRETE AND CEMENT:...

Mixing Concrete by hand, cement mixer or using ready mix

Mixing concrete using a cement mixer. Start the machine running with the drum at about 45°. Keep the mixer running until the mixer has been emptied. Add about half the ballast (or half the sand and half the gravel) required. Add a small amount of water and allow it ....

How To Make Concrete Tiles Duraamen

How To Make Concrete Tiles. You need a mix, water or a polymer, integral color that is added while mixing, topical colors like stains and dyes and finally sealers to protect the finish. Photo 1 – In the first exterior image above, the tile was made in precast pieces about 2 inches thick in approximately 3 foot squares using a typical Portland cement....

Concrete Mix Design | Stonemont Solutions

This integration is extremely important for vertically integrated companies that need realtime access to aggregate product information to create and/or adjust concrete mixes. Concrete mix component properties can be easily updated and pushed down to all mixes that use that component....

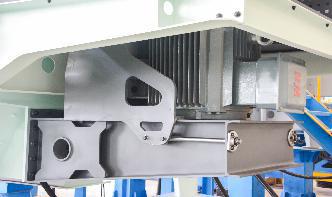

Concrete Products Machines Columbia Machine

Proven in the most demanding environments. Columbia's concrete products machines have earned a reputation for superior engineering, unparalleled performance and topquality production. Our production machines employ fieldproven technologies to deliver products unsurpassed in ....

The Concrete Construction Process

Concrete mixing trucks can be used to transport alreadymixed concrete, or the mixing can actually be performed by the truck as it is traveling to the site. One potential disadvantage of readymixed concrete is that the time required to transport the concrete to the site may use up too much of the early period of good workability....

Top 16 Mistakes People Make When Installing Concrete ...

Everything from the mix design, quantity of concrete to purchase, site preparation, tools, weather forecast, placement process, form removal and curing process need to be . Continue reading "Top 16 Mistakes People Make When Installing Concrete"...

MC250/350 Curb Mix Information Curb Building Machines

the 28 day strength of conventional concrete mixes. The advantage of using curb mix is that it trowels easily and can be finished immediately after being placed. As the curb is a homogeneous mix, placing expansion joints is easy. A concrete mix provides a much stronger product, usually exceeding 3,000 ....

Concrete Mix Ratios for Making Bricks with Moulds

Concrete Mix Ratios for Making Bricks with Moulds; How To Work Out The Concrete Mix For Your Mould. For ease of calculation, we work by volume and not weight. Thus 250ml of oxide would be 1 cup of powder, or 5ml would be one teaspoon. If using 1 Litre of cement, use an old 1 litre bottle and fill that. Once you have measured the volume you can ......

Concrete Mix Attributes, Instructions and Slumps

Mar 19, 2019· A concrete mix is like a chef's good recipe. Concrete is composed of aggregates, Portland cement, water, and any other cementitious material or chemical admixture. Some concrete mixes will have entrapped air by using admixture or airentraining cement....

A MIX DESIGN METHODOLOGY FOR CONCRETE BLOCK .

The properties of this particular type of concrete do not depend exclusively on the water: cement ratio and are rather influenced by the size and type of vibrocompression machine employed. Hence, the existing mix design methods for this type of concrete require excessively arduous, expensive, and time consuming tests in concrete plants....

Concrete Mixers Concrete Mixer Machine Latest Price ...

Mixing Drum: Heavy duty MS drum with bearing bottom 10mm center top cone 6 mm. This is easily carried from slab to slab and used in...

How concrete is made material, manufacture, making, how ...

Mixing 3 The cement is then mixed with the other ingredients: aggregates (sand, gravel, or crushed stone), admixtures, fibers, and water. Aggregates are preblended or added at the readymix concrete plant under normal operating conditions....

How Much Concrete Can Be Mixed in a 6CubicFoot Mixer?

Each 80pound bag of readymix concrete requires about 6 pints of water, for a total weight per bag of pounds. Five bags of readymix produces 3 cubic feet of wet mix that weighs approximately pounds. Check the mixer operation manual for maximum weight limits to be sure you're working within the safe limits of the machine....

Concrete Equipment For Sale | IronPlanet

Concrete Equipment for Sale Buy and sell unused and used Concrete Equipment at IronPlanet. Whether looking for a Concrete V ibrators, Trailer Mounted Concrete Pump s or some other Misc. Concrete Equipment, IronPlanet has the Concrete Equipment to help efficiently and effectively complete your job....

Concrete Mix Design Guide

Concrete", specifically Chapter 6, "Procedure" and Appendix 1, "Metric (SI) System Adaptation. This guide is to be used in conjunction with the Concrete Mix Design calculation for selecting proportions for initial concrete mix design. General: There are two methods for selecting the concrete mix proportions, by Weight Basis ......

Cellular Concrete Equipment | Richway

Continuous Production Machines. Produce cellular concrete more efficiently with our continuous production machines. All of our continuous production machines have integrated pumps that allow the and slurry to be mixed inline and pumped to the point of ....

What is the mix ratio for c35 concrete? Quora

Jan 12, 2018· Related Questions More Answers Below. The assumption is gravel concrete, cement strength grade is, then the material per cubic meter is: KG water: 205 cement: 466 sand: 571 stones: 1158 mixture ratio: water: cement: 1 sand: gravel: sand rate: 33% water cement ratio: ...

Concrete Mix Design (AS per ACI code) with Excel Sheets ...

Concrete Mix Design Excel Sheets. Comprehensive Excel spreadsheet for concrete mix design and batching can save up to 100 mixes. Unique easy to use features for proportioning aggregates etc. Up to six aggregates, four cements and five admix can be blended in any one mix....

Lab 1 – Concrete Proportioning, Mixing, and Testing

Concrete is a mixture of cement, sand, aggregate, water, and possibly an admixture. Proportions of each ingredient are adjusted to produce a wellbalanced mix. Concrete sets in as few as 10 hours and continues to harden and cure as long as moisture and unhydrated cement are present. However, most of the increase in strength occurs within a few weeks....

Concrete Materials Mix Components The Concrete Network

Any concrete that will be exposed to freezethaw and deicing salts must have entrained air to prevent spalling of the surface and even complete breakdown of the concrete. In severe exposure areas, the air content should vary from % for 3/8 inch maximum sized aggregate to % for 1 ½ inch aggregate (typically with a tolerance of plus or minus 1%)....

What is the Process of Making Concrete? | Sciencing

What is the Process of Making Concrete?. Before it can become a driveway, patio or foundation, concrete must be combined from a mixture of sand, aggregate or gravel, Portland cement and water. Once these ingredients are mixed together, the wet concrete product is poured into a form that serves as a mold. Within a ......

Concrete Block Making Machine

Features Of Aimix Concrete Block Making Machine : The forming of the block is mainly by using hydraulic pressure, mechanical pressure as auxiliary, and the pressure is increased with vibration. The final product can gain the compression strength over 15Mpa with good frostresistance and impermeability, good sound and heat insulation, accurate size....

How To Make Concrete Tiles Duraamen

Summary How To Make Concrete Tile. There are 3 basic ways to make concrete tile. You can make molds and pour concrete into your desired size and shape. It can be integrally colored and topically stained and sealed. You can use self leveling concrete or GFRC ( Glass fiber Reinforced Concrete in Molds), which is a light weight product and very ......

HESS GROUP Concrete block machinery for pavers, blocks ...

HESS provides a symbiosis of flexibility, product quality and speed, hereby combining everything you need in order to make your project successful. The HESS GROUP provides you the competitive edge in the field of concrete block making machines, concrete mixing devices and moulds....