heat mass balance for vertical raw mill

ATTRITOR GRINDING MILLS AND NEW DEVELOPMENTS

or feed rate of raw material. In addition to reducing particle size, Attritors also can create the highest intensity intimate blending of dissimilar materials. Specific chemicals or additives can also be introduced to the mill during the grinding process to achieve the ultimate dispersing or coating on the dry solid particles. II....

Potential for energy savings by heat recovery in an ...

Jun 25, 2016· The detailed mass and energy balance and pinch analysis have identified opportunities for further energy savings by integrated heat recovery, albeit small savings relative to the total energy input. In Fig. 12, the options for heat recovery are compared....

Flotation Material Balancing Excel Solver: Mass Balance ...

For a flotation circuit, material balance calculations define an engineering problem where flow parameters between unit operations are partly known. The purpose of a material balancing is to mathematically examine the known flow parameters to solve for the unknown flow parameters. Two main types of material balances are commonly made: design material balance operating plant material balance....

Overall heat transfer coefficient for shell and tube heat ...

Sep 17, 2017· Radiation. The heat transfer can be determined from the sensible heat change in either fluid over the length of the pipe in which the heat transfer occurs. The hot side liquid temperature T1, cold side liquid temperature T4, and the temperatures ....

VRM HEAT MASS BALANCES SHEET Page 1 of 18

VRM HEAT MASS BALANCES SHEET. Dear all. i need to know what the method for calculate heat and mass balance of vertical roller mill with capacity 400TPH(.5%MOISURE) and kiln capacity 4500TPD,six stage? Reply. Know the answer to this question? Join the community and register for a free guest account to post a reply....

DESIGN OF GAS OIL SEPERATION PLANT ResearchGate

mass balance section our sole purpose was to calculate final mass flow rate of separated gas and oil which have been pass through separators, dehydrator and distillation columns....

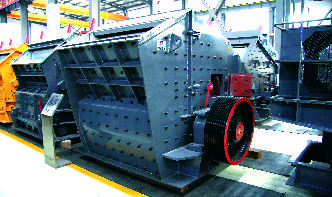

Ball Mill Design/Power Calculation

A wet grinding ball mill in closed circuit is to be fed 100 TPH of a material with a work index of 15 and a size distribution of 80% passing ¼ inch (6350 microns). The required product size distribution is to be 80% passing 100 mesh (149 microns). In order to determine the power requirement, the steps are as ....

Cement Process Energy Saving ECCJ

Cement Process Energy Saving October, 2006 The Energy Conservation Center, Japan Tro Kawase. Laos 2 Water Layout of one Japanese cement factory Waste tire yard Coal yard Electrostatic Precipitator Raw mill crusher SP calciner Rotary kiln Cement silo Shipping pier Birdeye View of Japanese Cement Factory ... by heat balance ......

Cement mill Wikipedia

Temperature control. Heat generated in the grinding process causes gypsum (CaSO 4 .2H 2 O) to lose water, forming bassanite (CaSO 4 . 2 O) or γanhydrite (CaSO 4 .~ 2 O). The latter minerals are rapidly soluble, and about 2% of these in cement is needed to ....

How to Make Sugar from Sugar Cane Howtopedia english

• A manual mill with a throughput of around 100 litres per hour. (More suitable for juice drinks than gur production.) Penagos Hermanos CIA Ltda Apartado Aereo 689, Bucaramanga, Colombia • A vertical roll, animal powered crusher, capacity of 46 tonnes of cane per day....

Cylinders and Pipes Conductive Heat Losses

Conductive Heat Transfer Heat transfer takes place as conduction in a soilid if there is a temperature gradient; Copper Tubes Heat Loss Heat loss from uninsulated copper tubes at various temperature differences between tube and air; Copper Tubes Insulation and Heat Loss Heat loss to surrounding air from insulated copper tubes...

Mass balance Wikipedia

A mass balance, also called a material balance, is an application of conservation of mass to the analysis of physical systems. By accounting for material entering and leaving a system, mass flows can be identified which might have been unknown, or difficult to measure without this technique....

S Hess Initial study on solar process heat for South 3 2 ...

lar process heat (SPH) integration are the generation of live steam and exhaust steam, the preheating of boiler feed water, the drying of bagasse and raw sugar, and the heating of clear juice. Without additional thermal storage, ST systems can supply between 12 and 27 % of the heat demand of these processes. The estimated...

11. HEAT AND MATERIAL BALANCE Chemistry, Software

The new heat balance module offers several ways to calculate heat and material balances: 1. The user types the input and output species, temperatures and amounts into the IN1 and OUT1 sheets respectively. This is a simple way to calculate heat and material ....

Series V SME Audio

Stainless steel vertical shaft, ground and thread ground, with integral 16mm diameter flange to couple shaft and yoke. 23mm diameter steel pillar, heat treated, ground and honed, carries two 17mm ball races, widely spaced to resist tilt....

Cement Manufacturing Process | Phases | Flow Chart ...

Aug 30, 2012· Raw mix is stored in a prehomogenization pile after grinding raw mix to fine powder. Cement Manufacturing Process Phase III: Preheating Raw Material. After final grinding, the material is ready to face the preheating chamber. Preheater chamber consists of series of vertical cyclone from where the raw material passes before facing the kiln....

Steps in the Modern Steelmaking Process

May 16, 2019· Ironmaking, the first step, involves the raw inputs of iron ore, coke, and lime being melted in a blast furnace. The resulting molten iron also referred to as hot metal still contains percent carbon and other impurities that make it brittle....

(PDF) Analysis of material flow and consumption in cement ...

excess heat from the kiln in the process line or from a stove. The hot ... The coal mill is a vertical roller mill, in. ... Mass balance of the raw mill under investigation....

Reheating furnaces in steel plants – IspatGuru

Apr 13, 2013· In steel plants reheating furnaces are used in hot rolling mills to heat the steel stock (Billets, blooms or slabs) to temperatures of around 1200 deg C which is suitable for plastic deformation of steel and hence for rolling in the mill....

Mill Heat Balance Calculation

heat mass balance for vertical raw mill waldkinderkrippech. How To Do Heat Balance Of Mill In Power Plant How To Do Heat Balance Of Mill In Power Plant Raw Mill Cement Plant Heat Balance Process Calculation and raw . Get Price. HEAT BALANCE BOILER Dalhousie University....

heat balance grinding in ball mill

mass and heat balance in raw mill grinding pdf Ball mills Internal installations and Cement Seminars and Courses 2015 FL Jan 27, 2015 Mass and heat balance Separator types and mode of operation Separator efficiency, particle size distribution and Tromp curv Grinding media charges and mill linings Performance testing of ball mills Practical ball ......

The Radiant Time Series Cooling Load Calculation Procedure

series coefficients and gives a brief comparison to the heat balance method. INTRODUCTION The radiant time series (RTS) method is a new method, derived directly fi"om the heat balance method, for performing design cooling load calculations. It effectively replaces all other simplified (nonheatbalance) methods such as the cooling load...

raw mill heat balance

heat mass balance for vertical raw mill BINQ Mining. mass and heat balance calculator (Vertical coal mill) | Our crusher, The raw coal is fed into the center of the millThis is an intermediate speed pulverizer The vertical,heat and mass balance, kJ/kg of coal »More detailed... HEAT BALANCE IN BALL MILL YouTube...