induction furnace slag processing

Induction melting furnace manufacturer, Induction furnace ...

Our products: New KGCL induction furnace, metal melting furnace, common KGPS Induction Melting Furnace, and new KGCL series which has one power supply with two furnace bodyworks at the same time (one for smelting and the other for heating preservation)....

STEEL MAKING BY INDUCTION FURNACE Basai Steels Pvt Ltd.

The greatest advantage of the Induction Furnace is its low capital cost compared with other types of Melting Units. Its installation is relatively easier and its operation simpler. Among other advantages, there is very little heat loss from the furnace as he bath is constantly covered and there is practically no noise during its operation....

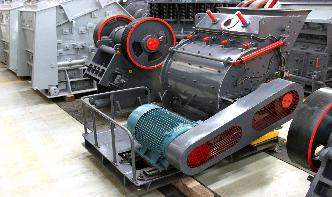

slag crushing machine for induction furnace

Crude steel is also produced from scrap in electric furnaces, sometimes with the ... takes place in the cupola furnace, with increasing use of induction furnaces. ... air from transfer stations, chutes, crushers etc. is cleaned by a hot sieve system. .... Part is used to produce iron slag Portland cement and blast furnace cement....

Induction Furnace Slag Processing

induction furnace slag processing bricks india. Bricks – IndiaMART. Processing. Steel scrap is re melted and slag is used in manufacturing of slag/fly ash bricks, which find Six tonne induction furnace; Three ......

Chemical characteristics of iron and steel slag : NIPPON ...

The primary components of iron and steel slag are limestone (CaO) and silica (SiO 2).Other components of blast furnace slag include alumina (Alsub>2 O 3) and magnesium oxide (MgO), as well as a small amount of sulfur (S), while steelmaking slag contains iron oxide (FeO) and magnesium oxide (MgO).In the case of steelmaking slag, the slag contains metal elements (such as iron) in oxide form ......

slag crushing process of induction furnace

induction furnace iron slag processing ball mill for induction furnace slag. slag,iron furnace slag,slag processing,induction Ball mill is successfully used for polishing. crushing, Check price. Contact Supplier MF 1826 Properties and Uses of Iron and Steel Slag. Get Price...

slag haulers models

ingot furnace slag used in; copper slag crushing units; slag cement manufacturing 2013 india; crush furnace slag in; slag pot carriers from china; the entire production of stainless steel slag; copper recovery from slag in india; metal separation from induction furnace slag; slag processing ....

MechanicalandDurabilityPropertiesof InductionFurnace .

processing, thereby rendering the aggregate susceptible to permeation, diffusion, and absorption of fluids [11]. ... discussed the application of IFS and cupola furnace slag ... Figure 4: Stack of Induction Furnace slag. Figure 5: Sieving of IF slag using standard sieves. Advances in Civil Engineering 3. For cases where both RA and IFS were ......

Gold and Silver Refining Mineral Processing Metallurgy

Ensure that the induction furnace FR557, the furnace screw feeder CV579 and the furnace dust collector DC 571 are available to operate. Start the furnace and allow the furnace to heat up to 2000 degrees Fahrenheit. Check that the furnace cooling system has an ....

furnace slag magnetic separator in india made YouTube

Jun 10, 2019· Slag Raymond Mill Made In ...manganese ore dry magnetic separator from .furnace slag magnetic separator in india made manufacturer of magnetic separator for manganese processing....

Method of extraction of copper from slag generated in the ...

A known method of extraction of copper from slags, including slag grinding and processing of crushed slag acid [1]. The known method is not used for separation of copper from slag generated in the melting ligatures "coppermanganese in induction furnaces. In addition, this method does not provide high recovery of copper....

Simple analysis between electric arc furnace and induction ...

Simple analysis between electric arc furnace and induction furnace in smelting. Features on the refining ability,The electric arc furnace has stronger ability in dephosphorization desulfuration and deoxidation than induction furnace. The slag in induction furnace is cold; furnace slag temperature is maintained by molten steel. Electric arc ......

ore processing furnace

Use of an induction furnace for the production of iron from ore Google. A method of using an induction furnace to process iron ore into an iron product such as pig iron in which iron ore is the main or exclusive source of iron fed into the induction furnace. Ore Processing ....

Electric arc furnace slag processing installation | ...

Electric arc furnace slag processing installation. Location: Luxemburg Industry: Bottom ash (electric arc furnace slag) Capacity: Turnkey installation to crush, sort and classify electric arc furnace slag. This slag is produced during the manufacture of crude steel by the electric arc furnace (EAF) process....

Coreless Induction Furnace Principle your electrical guide

Mar 08, 2017· In this case, also the charge to be melted is made the secondary of the transformer. The primary is wound over the crucible itself. The eddy currents produced in the charge not only heat it up but also account for the stirring action. It is the basic coreless induction furnace principle....

how does an induction furnace work? | Yahoo Answers

Oct 07, 2007· Induction heating can be used to bond conductive materials. As a manufacturing process, it is fast and consistent. In homes, induction ovens are becoming popular ways to cook, but they are also used for furnaces to heat homes. Antitamper seals on the tops of medicines and drinks are often created using induction heating....

Treatment and characterisation of electric arc furnace ...

Its effectiveness as hydraulic material is examined before and after heat treatment in an induction furnace. The study shows that while there is a marginal reduction in the early age strength of the Portland Slag Cement mortar, the later age strength does not suffer by replacing up to 20% of Ground Granulated Blast Furnace Slag (GGBFS) by EAF slag....

`INDUREF' Induction Ladle Refining Furnace for .

diminutive yields rendering them uneconomical to operate and making the processing of low carbon steel ... The development of the medium frequency induction furnace (MF induction furnace) has been a boon to the ... The low thermal conductivity of the slag layer is the ratecontrolling factor. High radiation losses due to the high temperature ......

ingot furnace slag crushing plant[mining plant]

slag,iron furnace slag,slag processing,induction . Slag of steel plant of furnace containing 10 to 20% ... product !because our crusher separator plant is simple efficient source of purifying metal from slag or furnace......

extracting precious metals from slag using induction furnace

Nov 02, 2012· steel slag metal recovery method – Crusher South Africa. slag,iron furnace slag,slag processing,induction furnace slag . Method for precious metal recovery from slag . Separation of Metals from a Slag Using a Multicell . »More detailed...

A PROCESS FOR REFINING STEEL IN INDUCTION FURNACE

A process for refining steel in induction furnace comprising steps of: (a) providing an induction furnace having basic or neutral refractory lining; (b) providing slag having basicity of the order of to 4; and (c) maintaining iron oxide content (FeO) of slag in the induction furnace for continuous oxidation and removal of phosphorus from slag....

(PDF) Electric Furnace Steelmaking ResearchGate

PDF | This chapter deals with electric furnace steelmaking, a tool for the massive production of steels, which is responsible for 30% of the current worldwide production. The EAF is a field for ......

How Does an Electric ARC Furnace Work? | Hunker

May 30, 2018· How Does an Electric ARC Furnace Work? By Blake Flournoy | May 30, 2018 ... coal and limestone fuel, making it primarily suitable for processing iron ore, while induction and crucible furnaces, heated with electrically charged copper coils and hot plates respectively, deliver an efficient and controlled heat that makes them perfect for working ......