cement clinker mills

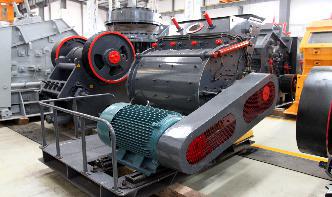

Cement mill

Cement mill is also called cement ball mill, which is mainly used for grinding cement clinker in the cement production process. It is one of the important cement equipment. The output of cement mill is 21~155 t/h, and the specific surface area of cement is 3300~3800 cm ² /g....

Cement

At this stage, further samples are collected and the clinker is transported to silos and hoppers where it is stored with the other additive materials that go into the cement: gypsum, limestone, pozzolan or slag. The percentage of each one of these additives will determine the type of cement....

Our Factory – Kuwait Cement Company

First: The Cement Mills. The company set up its plant for producing cement in East Shuaiba Industrial Area which commenced production on 15 th May 1972 by installing two Mills for grinding Clinker and Gypsum to produce Cement, with a production capacity of 300,000 MT. The company has progressively developed through the years to increase the productivity of the grinding to achieve its ....

Stage 4: Finish Process | Cement Production

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement is currently ground in ball mills....

process of operating a cement mill

Rockwell Automation ... cement mill, Process Perfecter allows for more robust realtime control and optimization than... Get Price. Mining, mineral processing and cement SKF ... operating close to the process parameter set points, ... Raw mill. Cement. Clinker gas solid. Temperature and residence time during cement... Get Price. Jura Cement's ......

clinker ball mill for cement grinding plant

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills....

ZK Ball Mill_Cement Mill_Rotary Kiln_Grinding Equipment

Main Equipment: Cement Mill,Cement Kiln,Bag Filter The cement clinker grinding plant or cement grinding station acts as an individual production line in the last period of the cement ....

China Cement Clinker, Cement Clinker Manufacturers ...

China Cement Clinker manufacturers Select 2019 high quality Cement Clinker products in best price from certified Chinese Cement manufacturers, Cement Brick suppliers, wholesalers and factory on ...

Raw Mill In Cement Plant,Cement Making Plant

This paper mainly introduces the raw mill in cement plant. In order to achieve the desired setting qualities in the finished product, a quantity (28%, but typically 5%) of calcium sulfate (usually gypsum or anhydrite) is added to the clinker and the mixture is finely ground to form the finished cement powder. This is achieved in a cement raw mill....

Clinker (cement) Wikipedia

In the manufacture of Portland cement, clinker occurs as lumps or nodules, usually 3 millimetres ( in) to 25 millimetres ( in) in diameter, produced by sintering (fusing together without melting to the point of liquefaction) limestone and aluminosilicate materials such as clay during the cement kiln stage....

Clinker Cement – AvInTrading

In the manufacture of Portland Cement, clinker occurs as lumps or nodules, usually 3 millimeters ( in) to 25 millimeters ( in) in diameter, produced by sintering (fused together without melting to the point of liquefaction) limestone and alum inosilicate materials such as clay during the cement ....

Portland Cement Manufacturing US EPA

Portland Cement Manufacturing Process Description17 Portland cement is a fine powder, gray or white in color, that consists of a mixture of hydraulic cement materials comprising primarily calcium silicates, aluminates and aluminoferrites. More than 30 raw materials are known to be used in the manufacture of portland cement, and these...

CHAENGMining Equipment Suppliers

Cement Ball Mill. The ball mill for clinker is an efficient tool for fine powder grinding. It is mainly used to grind the clinker and raw materials in cement industry and also can be applied in metallurgy, chemical, electric power and other industries to grind all kinds of ores. Cement ball mill is not only suitable for overflow grinding....

Cement mill notebook SlideShare

Jan 07, 2015· CEMENT INDUSTRY Cement Mill Notebook QATAR NATIONAL CEMENT COMPANY DOHAQATAR 2010 na2elll ... Decrease the opening degree of the circulating fan damper. Storage of clinker Cement: Clinker to finish mills should not exceed 100 ºC. Loading of hot (>150 ºC) clinker to concrete silos should be avoided as spalling and de ......

Cement Production Line cement plant,ball mill,vertical ...

In the cement production line, producing 1 ton of Cement need grind at least 3 tons of materials (including raw materials, fuel, clinker, mixed materials,gypsum).Grinding operation consumes about 60% of total power in cement plants, raw material grinding more than 30%, while coal mill used in cement plant consumes 3%, cement grinding about 40%....

Masonry Cement – Monarch Cement Company

Used primarily in masonry and plastering construction, our masonry cement is a hydraulic cement specially formulated and manufactured from ground Portland clinker and ground limestone. We add a small amount of gypsum and admixture to enhance masonry properties, such as setting time, water retention and durability....

Cost Of Cement Clinker Grinding PlantStone Crusher Sale ...

In some ore processing and production processes, Cement Clinker Grinding Mills are the main milling equipment. This type of Cement Clinker Grinding Mill is milled to a product size ranging from 325 mesh to 1800 mesh. The customer can adjust the particle size ....

Cement Grinding Mineral Processing Metallurgy

Metallurgical ContentRAW CEMENT GRINDINGWET VS DRY Grinding of CementCLINKER GRINDINGCement Grinding MillsHigh Efficiency Cement Grinding Mill The principle of Grate Discharge grinding is nearly universally adapted in the cement grinding industry. Grate Discharge Ball Mills are the rule rather than the exception. Rod Mills for raw and finish grinding begin to enter the picture....