how a roller mill works

Walk Through History . . . Mill Sites and Water Power ...

The mill sat on the lower raceway, just south of the Falmouth Bridge in Fredericksburg. It had the capacity of producing about 160 barrels of flour and 400 bushels of meal per day in the late 19th century. While the mill originally employed burr stones, a roller system was installed in the 1880s....

DIY Grain Mill with " rollers for about 30 : Homebrewing

Because I wanted to buy grain in bulk, but didn't want to pay 100 or more for a prebuilt grain mill, I decided to make my own. This is a DIY mill, and a cheap one at that, so does have its drawbacks (namely time to build). I got about 68% efficiency from this, whereas with my setup and commercially crushed grain I usually got 70%....

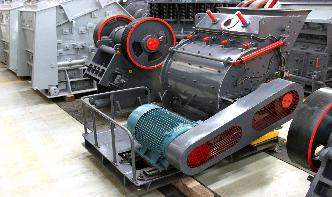

Grain Roller Mills | HIGH QUALITY GRAIN MILLS | COMPACT ...

The Affordable Grain Roller Mill Read below about our rare, but good value for money, grain roller mills. (2,) Our Grain Roller Mill design team have come up with the ultimate practical grain roller milling machine that is affordable and cost effective to hobby farmers and horse studs. Through well thought engineering and a lot of design work,....

How to make the roller mill work out of the ideal state ...

In addition to the price control of the roller stone mill, the roller can be adjusted. The mill makes it work well, so that the production efficiency of the entire roller mill can be greatly increased....

Roller Mill

Roller Mills. 24" wide discharge belt conveyor moves the processed grain away quickly and works well for filling trench silos Elevator discharge moves the milled grain up for discharge into a wagon, etc. Blower discharge model is available for cracking HMC (highmoisture corn) and ....

roller mills rugby how it works

roller mills rugby how it works. Roller Mills Rugby. Roller Mills Rugby website is dedicated to all those young players, Coach's and Manager's ( the Parents) that have been involved with the Northern Roller Mills Rugby Tournament since the first tournament in 1925....

Flour Mill Rolls used in the Roller Mills Roll Bodies

Therefore, our roller mill rolls or flour mill rolls have consistency and reliability. As a result, it improves the efficiency of your flour mill and reduces the downtime of your flour mill. Furthermore, we can supply you the flour mill rolls in smooth (grinded), fluted (grooved) or sandblasted (frosted) condition....

Rod Mills, How Do They Work?

Rod Mills, How Do They Work? Rod mills are very similar to ball mills, except they use long rods for grinding media. The rods grind the ore by tumbling within the the mill, similar to the grinding balls in a ball mill. To prevent the conditions leading to rod charge tangling, the length to diameter ratio is maintained at to ...

How Does a Hammer Mill Work?

of the mill retain coarse material for further grinding, while allowing properly sized materials to pass as finished product. Mill Evacuation: Hard, heavy materials such as . glass, stone, coarse wood. or . metals. can exit the mill via gravity. Lighter materials such as . finely ground wood, paper. and other . low density materials...

Make a Ball Mill in 5 Minutes: 4 Steps

Make a Ball Mill in 5 Minutes: This is for all the pyro nuts that I came across on Instructables. This can be used to grind chemicals to a very fine grain or to polish says "A ball mill is a type of grinder used to grind materials into extremely fine powder for use i......

Roller Mill Manufacturing | Dalhart | R R Machine Works ...

RR Machine Works is located on 10 acres in Dalhart, TX. Our facility is equipped to service facilities and production locally, nationally and internationally. Our state of the art equipment and highly trained personnel offer unmatched service and quality....

how coal roller mill work

Roller mills are typically used in coal fired power ... 1: Grinding rollers in roller mills are subject to considerable wear; .... Regeneration work is typically carried. Get Price...

The Working Principle of Hammer Mills (Stepbystep Guide ...

The Working Principle of Hammer Mills (Stepbystep Guide) A hammer mill is an essential machine in the pharmaceutical and food processing industries. You can use it to crush, pulverize, shred, grind and reduce material to suitable sizes....

how vertical roller mill works

Vertical Roller Mill Mobile Cone Crusher. LUM series of ultrafine vertical roller mill is a company with years of experience in the production mill, ... By vertical roller mill grinding abrasive layer principle, the material stays in the ground a short time, reduce ... Vertical Roller Mill Works. Get Price...

how it works roller mill Indonesia

HOW IT WORKS roller mill wildpeppersf How the Roller Mills Changed the Milling Industry Angelfire HOW IT WORKS roller mill,This is the way it was both in England and when it came to this country The millstone was the miller's symbol of his art and his industry, and they were reluctant to accept roller mills in place of the millstone One ......

What are the differences between a water mill and a flour ...

Jun 07, 2019· A water mill is a mill powered by water running through a water wheel, which turns whatever machinery is being used. They were used for grinding grain, but also for things like fulling cloth (processing it to make it smoother and tighter) for oper......

how does a six roller mill work

The two roller configuration mills are commonly called grist mills, malt mills, dry mills or roller mills. The two roller mill is designed to crack malt, keeping the hull intact for mash. The single pair, or two roller configuration, is suitable for use with all malt varieties as well as nonmalted grain....

cement coal mill roller mill works

Roller Mill Components · Roller mills, bowl mills, or vertical roller mills offer size reduction of bulk materials in coalfired power plants and cement works. In coalfired power plants roller mills are used to grind coal, while in cement works they grind coal, raw meal and more recently, clinker. Get price...

Kan Roll Roller Mill | Dalhart | R R Machine Works, Inc.

Roller Mill. To make money feeding animals, you need to have good feed utilization and efficiency in operations and that is why KanRoll Roller Mills are the perfect solution for any highvolume feeding operation. You choose the desired roll in feed rations, and RR Machine Works manufactures KanRoll Roller Mills keeping labor costs......

how vertical roller mill works

vertical roller mill smecrusher | Seeking Alpha How Vertical Roller Mill Works: It has two pairs of grinding rollers, each pair of roller composed of two narrow rollers, mounted on the same axis and can rotate at different speeds. Get Price; How Vertical Roller Mill Works . Vertical roller mill from SBM zoocode Vertical roller mill has many ......

What is a Sand Mill?

Jul 10, 2019· Many sand mills produce very small particles on the first pass, with the particles passing through a mesh screen. Others have recapture systems, allowing people to pass the mixture through the sand mill again to make it finer and more even. The design works by agitating the sand, rather than creating pressure,......

Should I choose a Roller Mill or Hammer Mill Grinder Mixer ...

Jul 19, 2018· The above photo shows Roller Mill Grinder Mixer featuring a sharp tooth design. The chart below describes which tooth design works best with each type of feed. While the Roller Mill and Hammer Mill Grinder Mixer options are there to help you feed your livestock, they both come with different features to help you find what works best for your farming operation....

How the Mill Works Operation of a Historic Grist Mill ...

How the Mill Works. It starts with the grain. Of course, grist mills grind a variety of grains, such as wheat, rye and corn. But in Rhode Island, particularly at Gray's Grist Mill, native grown corn, particularly Narragansett White Flint Corn, is the most common "grist for the mill."...

Grain Mill recommendations | Community | BeerAdvocate

Jun 30, 2019· For the OP, if you search this Forum for "Grain Mill" you'll find what most people use/recommend. That said, for me it's a 2roller MM, gap of and make it spicknspan after each use. Two major advantages you might not be realizing: 1) Cost, if buying in bulk the Mill ....

Wheat Roller Flour Mill Milling Section Roller Mill ...

The other slow roll is controlled by using the pinion set of required differential ratio. The wheat is fed to the rolls through feed rolls with suitable control. The offered Roller Mills are for the milling rolls of barrel dia 250mm and 1000 mm length. The rollers mills are of casted body and housings ....