ceramic machine process flow

The Manufacturing Process of Ceramic Floor Tiles Wall ...

Firing is the most vital procedure in the entire ceramic tiles manufacturing process. So after the tiles are applied with glaze, continuous firing procedure follows inside the kiln. There are different types of kilns but the most appropriate and the most efficient kiln for tile manufacturing is the roller hearth kill or RHK....

Dongguan Jinri Ceramic Machinery Co., Ltd. Ceramic ...

Dongguan Jinri Ceramic Machinery Co., Ltd., Experts in Manufacturing and Exporting Ceramic dinnerware machinery, Ceramic kiln and 129 more Products. A ....

Silicon Carbide Production Process | SaintGobain Silicon ...

Silicon Carbide Production Process Silicon Carbide (SiC) is a synthetic mineral most commonly produced in electrical resistance furnaces, by the Acheson process, named after the American Acheson who invented it in 1891....

Forming Process | Glass Packaging Institute

The glass flow undergoes a "mixing action" created by the rotation of the ceramic tube. This helps to make the temperature consistent while the downward motion of the plunger accelerates the glass flow. This pumping action is timed with the shearing of the glass flow ....

Machine Tool Industry Kennametal

Getting the most out of a manufacturing process means a 3point partnership between the end user, the machine tool builder, and the tooling provider. The right partner works with you every step of the way, from the point of the spindle connection to the completed part. Let Kennametal's Machine Tool Industry (MTI) specialists be your partners....

MANUFACTURING PROPERTIES of ENGINEERING .

For ceramics, a Coulomb flow law is used: • Resilience The maximum amount of energy per unit volume which can be stored elastically. This energy is released upon unloading. This value can be calculated as the area under the elastic part of the stresstrain curve....

Flowchart Symbols

What is input and output in a flowchart? Input and output are the fundamental building blocks of a process used to describe a software program. For example, the input could be provided by a user like at an ATM machine or in a form online or it could data provided by ....

What do the Different Flowchart Shapes Mean?

In Process Mapping the circle represents an Inspection. At an inspection, the quality of the product is evaluated. The flow continues only if the product is approved. For most flowcharting you need only use the basic flowchart shapes listed above. Those listed below are included to be complete, but you don't have to use them....

LAPMASTER MODEL 15C LAPPING AND POLISHING .

A rough chemicalmechanicalpolishing (CMP) process, where a sample (such as a metal, ceramic, plastic, glass, or silicon substrate) is machined, smoothed, and planarized to a high degree of refinement or accuracy using a rotating, serrated, castironalloy circular plate and an abrasive slurry grit in water suspension applied...

Tape Casting Machines Keko Equipment

The CAM H series of tape casters are our most advanced tape casting machines suitable for highest production demands. Advanced drying regimes makes them very suitable for thick tape production. Numerous temperature and air flow sensors are installed for process control....

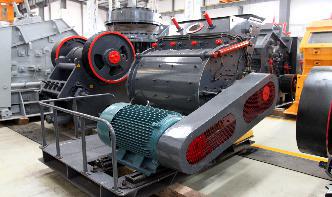

Manufacturing process of ceramic tiles SlideShare

Sep 06, 2015· Manufacturing process of ceramic tiles. Manufacturing Process of Ceramic Tiles Vamsi Krishna. Brief introduction to ceramic tiles 2. Process flow chart 3. Raw materials 4. Powder preparation 5. Continuous ball mill 6. Hydraulic press 8. Glazing and 9. 3. One of the largest groups of materials with the properties......

Clay Processing US EPA

is used extensively in the paper manufacturing industry. A process flow diagram for kaolin mining and dry processing is presented in Figure, and Figure illustrates the wet processing of kaolin. In the dry process, the raw material is crushed to the desired size, dried in rotary dryers,...

Magnet Manufacturing Process | How Are Magnets Made

Magnet Manufacturing Process There are several processes for making magnets, but the most common method is called Powder Metallurgy. In this process, a suitable composition is pulverized into fine powder, compacted and heated to cause densification via "liquid phase sintering"....

How ceramic filter is made material, used, processing ...

Raw Materials. Ceramic fibers of various compositions may also be added to improve certain properties. Other additives include binders (alumina hydrate, sodium silicate), antiing agents (silicone or alcohol), and other chemicals to improve slurry properties. Water is ....

(PDF) A Case Study: Ceramic Tile Production ResearchGate

PDF | In this chapter, a real case study dealing with the development and implementation of a manufacturing scheduling system is presented in detail. The goal is twofold. On one hand, we try to ......

Mechanical Engineering.: Manufacturing of brake disc

Manufacturing of brake disc ... The above mentioned are few that are used by industries to produce different products that could make up a machine such as a vehicle, electronic components or other day to day tools. ... In case such as this, ceramic composite brake discs are used, that are processed and used at high temperatures. These ceramic ......

Process Flow Chart of Garment Manufacturing Technology ...

Apparel manufacturing process starts from order receiving and end to the dispatching shipment of the finished garments. If we explain it, then it involves many processing steps like Product Design, Fabric Selection and Inspection, Pattern making, Grading, Marking, Spreading, Cutting, Bundling, Sewing, Pressing or Folding, Finishing and Detailing, Dyeing and Washing, QC and finally ending with a ....