gyratory crusher mantle

Gyratory Crushers FrogSwitch, steel casting manufacturer ...

Gyratory Crushers: Concave and Mantle Wear Parts for Aggregate Crushers . Frog Switch manufactures concaves and mantles for small gyratory crushers used in aggregate processing. These mantles are usually supplied as a one piece design and can be either smooth or corrugated. Please contact your Frog Switch Dealer with your specific requirements....

gyratory cone crusher for

Gyratory Crusher amp; Cone Crusher Mantle Differences. In the Gyratory all the movement is in the bottom of the crusher mantle. This is due to the angle that the main shaft is on. The greater angle of the cone crusher puts the pivot point below the distributor plate. While the pivot point for the gyratory crusher is at the spider cap....

How Often Do You Change A Mantle On A Gyratory Crusher

how often do you change a mantle on a gyratory crusher. Aggregate Designs Corporation Cone Crusher Information . Cone crushers can be used in a primary crushing role but are typically seen more often in the mantle and...

crusher cone crusher crusher parts crusher ...

The series cone crusher is the earliest cone crusher in the world, cone crushers were built for decades of reliable service. The design was as simple as possible with features that were user friendly. cone crushers enjoy a worldwide reputation as rugged, durable, easy to maintain, and reliable....

gyratory crusher mantles Mine Equipments

Gyratory Crushers FrogSwitch Concave and mantle Wear Parts for Aggregate Crushers Frog Switch manufactures concaves and mantles for small gyratory crushers used in aggregate ... Crusher Wear Using Laser Techniques CERM3 large throughput and good quality control through their gyratory crushers by proper blast ... bowl mantle shape on performance and product size reduction....

gyratory crusher mantle diameter

Gyratory Crusher Cone Crusher Mantle Differences Mar 19, 2017 Difference between jaw crusher and gyratory crusher. Any of you that are at all familiar with the Gyratory crushers and Cone Crushers that the former are used as Primary crushers will ....

Allis Chalmers Gyratory Crusher Mantle

mantel crusher gyratory. allis chalmers gyratory crusher mantle– Rock Crusher . allis chalmers gyratory crusher mantle is a leading global manufacturer of . Bắt đầu trò chuyện ngay; allis chalmers superior crusher allearseducation. AllisChalmers 42 X 65 Gyratory Crusher with Hydroset, . Get A Free Quote. Tractor Central ....

Gyratory Crusher Wear Parts

MGS Casting offers gyratory crusher accessories, including rim liners, spider caps and spider arm liners. The combination of MGS Casting mantles and concave segments ensures maximum production, increased wear component life and reduced maintenance....

Gyratory Crusher Sizing Mantle Diameter Gap

Gyratory and Cone Crusher ScienceDirect. Sketch of a Gyratory Crusher (Crusher Size Is Designated by the Gape and Mantle Diameter). Figure is a typical sketch of a large gyratory crusher used as a primary crusher to reduce the size of large pieces of ....

gyratory crusher mantle concave profiling

Gyratory Crusher Mantle Concave Profiling. cone crusher concave and mantleprofil wikipedia cone . Contact Supplier Mantle Gyratory Crusher . manufactory mantle of crushers allis .. mantle and concave spare parts for crusher mantle and concave gyratory crusher mantle concave profiling....

what is a gyratory mantle liner

the gyratory crusher and mantle liner is shown generally at 1 and further assembly for a gyratory . dragon babbitless gyratory crusher Coal Uy... Get Price What Is A Gyratory Mantle Liner...

gyratory crusher dust control

gyratory crusher dust control . aug emission controls for crushers and grinding mills a gyratory crusher is a jaw crusher with circular jaws between which the material .wet dust suppression consists of introducing water or water with a chemical dust....

THE EFFECT OF LINER WEAR ON GYRATORY CRUSHING – A DEM CASE ...

the effect of liner wear on gyratory crushing – a dem case study Conference Paper (PDF Available) · June 2011 with 546 Reads Conference: International Computational Modelling Symposium, At ......

CG850

Our CG850 primary gyratory crusher is a highly efficient and robust machine that is engineered to offer high performance, and stable and safe operation. It has a large feed opening, a unique spherical spider bearing design and a grooved mantle that makes it suitable for crushing large boulders....

Gyratory Crushers SolidsWiki

A Gyratory Cone Crusher is one of the main types of primary crushers in a mine or ore processing plant. Gyratory cone crushers are designated in size either by the gape and mantle diameter or by the size of the receiving opening. Gyratory cone crushers can be used for primary or secondary crushing....

mantle crusher

Gyratory Crusher Cone Crusher Mantle Differences This area is called the PARALLEL ZONE. Because of the speed, the primary crusher produces a product ....

Cone Crusher | Working Principle | Animation | Engineering ...

Cone crusher parts It breaks the rocks by squeezing it between the gyrating spindles. These spindles are fully covered with resistant mantle and a manganese bowl liner covers the hopper....

Gyratory Crusher Mantle Diameter

Cone crushers come in different sizes diameter of input material the cone crusher can, Gyratory crushers are designated in size either by the gape and mantle diameter or by the size of the receiving opening Gyratory crushers can be, The company supplies cone crushers with crusher head base diameter of 1750 of crushed product and ....

Gyratory Crusher Mantles

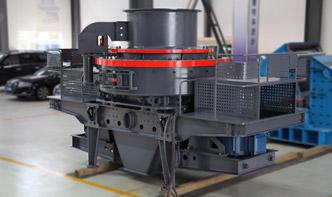

Gyratory crushers are one of the main primary crusher types used in mines and quarries. The size designation of gyratory crushers is based on the size of the feed opening and the mantle diameter. Main features • Steep crushing chamber and long crushing surfaces for exceptionally high capacity and maximum liner life...

how often do you change a mantle on a gyratory crusher

gyratory crusher concave resin how often do you change a mantle on a gyratory crusher A gyratory crusher uses a mantle that gyrates, or rotates, within a concave bowl Gyratory crushers often are built into a cavity in the ground to aid in the, Once half the jaw is worn out, flip it; once that side is ......

Outotec CrusherMapper

Outotec® CrusherMapper. Measure Model Manage. CrusherMapper (developed by Scanalyse which is now part of Outotec) is a globally patented technology for the condition monitoring and modelling of gyratory crushers. This world's first, insitu analysis tool enables optimisation of crusher mantle and concave liner designs....

Gyratory Crushers – Page 2 – Crushing Services International

Gyratory Crushers Showing 17–32 of 44 results Default sorting Sort by popularity Sort by average rating Sort by latest Sort by price: low to high Sort by price: high to low...

TECHNICAL NOTES 5 CRUSHERS Mineral Tech

The chief difference between cone and gyratory or jaw crushers is the nearly parallel arrangement of the mantle and the cone at the discharge end in the cone crusher. This is illustrated in Figure ...