plant location and layout

ENH1195/EP456: Landscape Design: Drawing a Planting Plan

Preliminary plans show the proposed layout of the individual plant material. The quick sketches are used to explore different layouts and arrangements to get a rough idea of the size constraints and best locations for plants. Several preliminary plans are often used to create one final plan, taking the best ideas from each plan....

North America Service Locations Ambius

An office plant business cannot provide exceptional service without providing local service. Wherever you're located, you are never far away from an Ambius branch. As a result, we are a national office plant company with local office plant locations throughout North America....

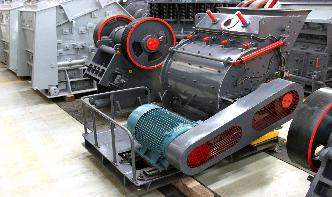

Plant Design and Operations [Book]

Plant Design and Operations provides practical guidance on the design, operation, and maintenance of process facilities. The book is based on years of handson experience gathered during the design and operation of a wide range of facilities in many different types of industry including chemicals, refining, offshore oil and gas, and pipelines....

Where are the Patanjali's manufacturing plants? Quora

Feb 22, 2016· Patanjali Food and Herbal Park at Haridwar is the main production facility operated by Patanjali Ayurved. Divya Pharmacy, Haridwar,India Divya Yog Sadhana, Haridwar,India Divya Prakashan, Haridwar, India Patanjali Ayurveda Ltd., Haridwar,India Th......

Hydroelectric Power Plant : Layout, Working and Types ...

Hydroelectric Power Plant : Layout, Working and Types by Kiran Daware Power System. Tweet. Generation of electricity by hydropower (potential energy in stored water) is one of the cleanest methods of producing electric power. In 2012, hydroelectric power plants contributed about 16% of total electricity generation of the world....

DESIGN OF A COMMON EFFLUENT TREATMENT PLANT .

The effluent is then sent to the common effluent treatment plant for further treatment. The design criteria used here are: 1) the depth of the carbon bed is usually 2 to 3m; 2) The flow rate usually varies between to m3/ and contact periods are between 10 to 50 minutes,...

Operations Management – The Importance of Process and ...

Feb 02, 2012· Amine Drira, Henri Pierreval and Sonia HajriGabouj from the article Facility layout problems: A survey also assert that "Layout problems are found in several types of manufacturing systems. Typically, layout problems are related to the location of facilities (,machines, departments) in a plant....

The Best LowMaintenance Plants for Your Landscape | DIY

The double pink variety shown here, 'Sarah Bernhardt', is popular in mixed borders and as a specimen plant. Plant peonies in spring or fall, in full sun or in morning sun and afternoon shade in very hot summer regions. Plant the eyes, or growing points, 2" deep ....

MEATPACKING PLANTS

Inspection facilities for large layout—hogs. . .. 25 Hog casing stripping facilities 27 Suggested small plant layout 27 Suggested small plant layout 27 Suggested slaughtering department for all 27 species: combination two cattle bed single 27 rail hangoff and small stock layout 27 Suggested slaughtering department for all...

Levels of Facility Planning ...{Strategos}

But factory layout is only one of several detail levels. At Strategos, we find it useful to think of facility planning at five levels: I Global (Site Location) II Supra (Site Planning) III Macro (Building Layout) IV Micro (Workcell/Department Layout) V SubMicro (Workstation Design) At the Global level, we select a site location. This involves ......

4. Layout planning Industrial Engineering Stream

Apr 04, 2012· Layout Planning Models, Al h d d lgorithms and computerized Layout Planning References 1. Tompikins et al., Facility Planning,3rd edition, John Wiley Sons Ltd., Singapore,2003. 2. Richard et al., Facility Layout and Location: an analytical h 2 d diti PtiHllf IdiLtd 2002 4 1 approc, n e on, Prentice Hall o India ., . 3. DrIng....

Control room design

the layout of control rooms and the arrangement of panels, VDUs etc to ensure effective ergonomic operation of the plant in normal circumstances and in an emergency. Control room structure. For large plants, control rooms are likely to be situated in separate buildings away from the process plant ....

Plant Layout and Siting American Chemistry Council

Plant Layout Siting The purpose of this section is to provide considerations for safety aspects that could be affected by the location and layout of phosgene containing equipment with respect to workers, environmental receptors and the surrounding community. The design layout ....

SITE AND LAYOUT DESIGN GUIDANCE 2

24 SITE AND LAYOUT DESIGN GUIDANCE SITE AND LAYOUT DESIGN GUIDANCE 25. process will steer decisionmaking for the other elements of the site. A number of aspects of site layout and building type present security considerations and are discussed below. Clustered versus dispersed functions. There is a strong...

Plant Design and Operations [Book]

Plant Design and Operations provides practical guidance on the design, operation, and maintenance of process facilities. The book is based on years of handson experience gathered during the design and operation of a wide range of facilities in many different types of industry including chemicals, refining, offshore oil and gas, and pipelines....

Model and Layout tab location in AutoCAD 2015 products ...

You notice that the location of the Model and Layout tabs has changed in 2015 Autodesk® AutoCAD® products. Specifically, the Model/Layout tabs are now located in the lower left corner of the program, even if you have a palette docked to the left side of the program. Also, if you have two drawings opened and the windows are tiled, you no longer see Model/Layout tabs for each drawing....

SITE LAYOUT DESIGN Építéskivitelezési Tanszék

Detailed design of all onsite temporary and auxiliary structures, supplies, stores, etc. • Exact position (location) of main equipments • Location and layout (inner layout too) of auxiliary worksops, plants, yards • Locations and functions (assignments) of store areas, deposits • Detailed design of temporary buildings, offices...

Layout and Material Flow Optimization

Our layout optimization services are provided by industrial engineering consultants who are also experts in related productivity improvement methods such as lean six sigma, simulation, ergonomics, and work a result, PMC clients benefit from our overall productivity and quality improvement mindset when they engage PMC's layout optimization services....

Plant Location International | IBM

Plant Location International (PLI) is a specialized consulting service within IBM Global Business Services® acting as the global center of competence for Global Location Strategies. With a track record of six decades, PLI has established itself as a market leader in providing advice to companies on their location decisions, covering all ......