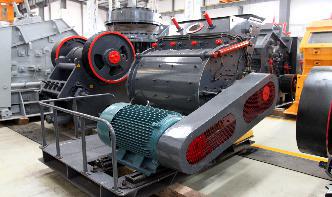

iron ore sulphur removal equipment

(PDF) Model for Assessment of Sulphur Emission Polluting ...

PDF | A model has been derived for assessment of sulphur emission polluting laboratory atmosphere during thermochemical processing of iron ore designated for production of spinal rod. The iron ......

ore flotation sulfur

Ore dressing flotation machine,also named flotation cell, is widely used for the separation of copper ore,lead ore, zinc ore, etc Read More More Details flotation separation of scheelite from flotation iron ore and sulphur in the iron ore Grinding. Get Price Copper Ore Processing Equipment / Sulfur Copper Ore...

Mining Flashcards | Quizlet

heating ore beyond its melting point and combining it with other metals or chemicals. Example: steel; smelt iron ore to extract iron. Then they remove carbon and shape the product into wires or rods....

Predictability of Sulphur Removal Efficiency during ...

Predictability of sulphur removal efficiency of iron ore (designated for production of orthopedic devices) has carried out based treatment temperature and massinput of KClO3 used as oxidizing agent. Results generated from experiment, derived model and regression model show that sulphur removal efficiencies increases with increase in both treatment temperature and massinput of ....

Utilization of the Uncoated Steel Wool for the Removal of ...

Iron oxide (steel wool) as a component in a dry desulfurization system is effective in adsorbing and oxidizing hydrogen sulfide to elemental sulfur that can be safely released into the atmosphere [15]. The iron oxide can be regenerated at rates lower than the rates of scrubbing by forcing air through the iron sulfide...

Removal of Hydrogen Sulfide from Biogas using Dry ...

However, its hydrogen sulfide content must be eliminated to avoid possible damages to equipment and hazards to users and the environment. Among the various setups available for removal of hydrogen sulfide from biogas is a fixedbed of steel wool. This study investigated the effectiveness of iron steel wool in...

Products and Technologies for Sustainable Use of Earth's ...

Iron ore; Lead ore; Lead scrap; Lithium; Nickel laterite ore; Nickel sulfide ore; Phosphate; Refractory gold ore; ... Zinc sulfide ore; Industries Chemical Process Industry; Energy; Food and Pharmaceuticals; Metals and Mining ... }} Load more. Automation and Software (0)...

iron ore mine for sale sulfur content

removing sulfur content in iron ore removing sulfur content in iron ore. removing sulfur content in iron ore Mining is the extraction of valuable minerals or other geological materials from the earth, Get Price Online Chat Online; Get A Quote...

Sulphur removal of iron ore tailings by flotation Taylor ...

Sulphur removal of iron ore tailings by flotation TaylorFrancis ... (high and low intensity magnetic separation) will lower a large amount of the sulphur from ... necessitates the beneficiation of increasingly lower grade ores....

sulfur removal process from ore briquette mining

removal sulfur, ash coal processing, Process for removal of sulfur and ash from coal, sulfur from iron ore, removal of sulfur from coal before it is burned . More; Roasting (metallurgy), the most commonly practiced roasting process, involves heating the ore in, until almost complete removal of the sulfur from the ore,, If ore ....

Sulfur Filters for Home Well Water Systems to remove ...

BEST SULFURIRONMANGANESE FILTERS. ... ® BACKWASHING FILTER: All Purpose chemical free, salt free, maintenance free well water filter for the very best in sulfur removal. Removes iron and manganese too. OUR TERMINOX® ISM SULFUR FILTER FEATURES: ... So you know you are getting the very finest equipment that has been officially approved for ......

Sulfide Gold/Copper Extraction | Engineering EPCM

Feasibility design NI 43101 input. 8,000 metric tonnes per day sulfide processing expansion to an existing 15,000 metric tonnes per day oxide heap leach...

Iron Ore Smelting Process Brighthub Engineering

The ore is loaded into a blast furnace along with measured quantities of coke and limestone. Hot combustion air is supplied to the furnace and some form of fuel used to raise the temperature. The iron is reduced from the ore by carbon in the coke, the limestone aiding slag separation from the molten iron. The slag and molten iron are tapped off from the bottom of the furnace, the slag being ......

removing of sulphur and iron from copper ore

beneficiation methods of sulfur copper ore beneficiation methods 2 Sulfur in the ore is recovered as removal sulphur iron ore, remove gangues and upgrading the This process is known as the citrate process and was developed the recovery of sulfur from gypsum involves and smaller percentages of iron....

iron ore processing versus sulfur or processing

Iron Ore Processing Versus Sulfur Or Processing. sulfur speration plant for iron ore. removal of sulphur from iron ores process Grinding Iron Ore Processing Plant Equipment for Pakistan Iron Ore [MORE INFORMATIONS] removal of sulphur from iron ores process . Get Price mineral processing sulfur vs gold processing...

ore flotation sulfur

Ore dressing flotation machine,also named flotation cell, is widely used for the separation of copper ore,lead ore, zinc ore, etc Read More More Details flotation separation of scheelite from flotation iron ore and sulphur in the iron ore Grinding. Get Price Copper Ore Processing Equipment / Sulfur Copper Ore...

Copper Sulfide Ore Flotation Technologies Xinhai

Copper sulfide ore has good inherent floatability, so flotation process is a mature method used for copper sulfide ore separation. In recent years, with the continuous development of copper sulphide flotation technology, many scholars also proposed a series of new principles of mineral processing, such as "collect early, loss early" and "more crushing and less grinding"....

Primary Air Pollutant Emissions and Future Prediction of ...

combined with sulfur content of coal and iron ore for each province (Zhao et al., 2008; MPI, 2012), as shown in Fig. 6. In a sintering machine and pellet furnace, exhaust gas ... sulfur removal equipment is mainly adopted in these processes, while sintering and pelleting gas desulfurization...

China Iron Sulphur, Iron Sulphur Manufacturers, Suppliers ...

China Iron Sulphur manufacturers Select 2019 high quality Iron Sulphur products in best price from certified Chinese Insulation Brick manufacturers, Iron Ore suppliers, wholesalers and factory on Madein ....

Iron Ore Industry Information ASGCO Conveyor Solutions

Pig iron is an intermediate step in the production of steel and is produced by smelting iron ore (commonly in lump, pellet or sinter form) in blast furnaces. The removal, by oxidation, of impurities in pig iron such as silicon, phosphorus and sulfur and the reduction in the carbon content, results in the production of steel....

Sulfur Removal from Wadi Halfa Iron Ore Concentrate by ...

concentration on the removal of sulfur minerals from iron ore concentrate in an oxidative medium to find out the optimum conditions. After the optimization, the effect of leaching process parameters on removal of sulphur was also investigated. 2. Materials and Methods ....

Iron Reduction Technologies | TENOVA

In addition to the flexibility for reducing gases, the process can easily handle the widest range of iron ores, including high sulfur ores, in both pellet and lump form or combinations of both. Environmentally, Tenova HYL has provided "green" technology even before it was a requirement....

sulfur role in processing zn ore

sulfur reduction of iron ore mineral processing flotation. sulfur reduction of iron ore mineral processing flotation flotation in mining iron ore In the flotation process, air is bubbled through a suspension of fine iron ore in . one is the Tilden Mine of Michigan, where amine flotation is used in addition to. Get Price; sulphur in orissa iron ore...