mining method and processing methods of iron ore deposits

Processing Methods | Diamcor Mining Inc.

Processing Methods. For alluvial type deposits crushing is rarely required and the material goes straight to screening. Depending on the processing method being employed, material under a certain chosen size fraction may go through a scrubbing system to clean the ore prior to ....

Mining Flashcards | Quizlet

A new cut is made parallel to the previous one and the process is repeated all over the site. The overburden is filled in the trench that the mineral deposit once filled. If filling does not restore the land, area strip mining leaves a wavy series of highly erodible hills of rubble called spoil banks....

Topic 5: Mining MethodsPart ISurface mining

Nov 02, 2011· Figure shows Open pit Mining method 2 February 2016 Prof. Dr. Harraz Presentation Mining Methods, Surface mining Benching Bench level intervals are to a large measure determined by the type of shovel or loader used, and these are selected on the basis of the character of the ore and the manner in which it breaks upon blasting and supports ......

From ore to steel – ArcelorMittal

As the world's leading steel and mining company, our business operations extend from the mining of iron ore and coal to the production of the full range of steel products and services. In 2016, we produced million tonnes of iron ore and million tonnes of coking coal, a form of carbonised coal burned in blast furnaces to melt iron....

Sampling Methods | MINING

This method is used to take samples from an outcrop. The tools are used hammer and chisel. Samples taken at the surface fresh and clean. This method is used only in a preliminary investigation. The results are unrepresentative of the actual state of mineralization. Chip sampling in underground mines:...

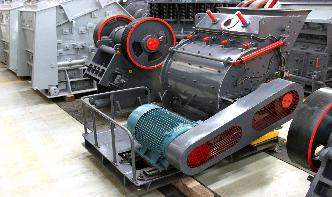

iron ore mining processing method liberia

Liberia crushers, Liberia grinders and screens for Liberia Iron Ore Mining iron ore mining processing method liberia,The Putu iron ore project is part of a 425km² exploration tenement located in southeast LiberiaIn the Liberia iron ore mining project, we have offered iron ore crushers and iron ore ball mill for the preprocessing of iron ......

Overview of Mineral Processing Methods ResearchGate

Overview of Mineral Processing Methods. ... Most of the rock deposits con tain metals or minerals. When the ... The electric power consumption by this process run on ore mining and processing ......

Mining : What is Mining? What are the 4 mining methods ...

What are the main mining methods? Four main methods of mining are available: underground, open surface (pit), placer and insitu mining. Underground mines are more expensive and often used to reach deposits that are deeper. Surface mines are usually used ....

Topic 3: Ore processing and metal recovery SlideShare

May 17, 2009· Topic 3: Ore processing and metal recovery From a series of 5 lectures on Metals, minerals, mining and (some of) its problems prepared for London Mining Network by Mark Muller 24 April 2009...

INTRODUCTION TO MINING

pertain to the ore deposit being mined. Mining is never properly done in isolation,nor is it an entity in itself. It is preceded by geologic investigations that locate the deposit and economic analyses that prove it financially feasible. Following extraction of the fuel, industrial mineral,or metallic ore,the runofmine material is generally cleaned...

Grade Blending for Iron Ore Processing – Optika Solutions

Sep 26, 2017· Grade Blending for Iron Ore Processing; ... Scope of the system that was to be modelled is the material flow between mining pits (cutbacks in the deposit) and the processing plant. Mining pits and processing plant were treated as "black boxes", meaning their behavior was only modelled on an abstract level. ... In addition, two methods for ......

Iron Ore Leaders in Mineral Processing Worldwide

With teams located in major mining regions worldwide, we can work with you to supply Iron Ore beneficiation solutions across all stages of the project lifecycle. To find out more about how we can drive down operational costs and extract maximum value from your mineral processing operations across the project lifecycle contact our local team today ....

[GIFS] The 5 Stages of the Mining Life Cycle | Operations ...

Aug 18, 2015· Mining operations are complex. They aren't your runofthemill type projects. These billion dollar complexes consist of various interconnected projects, operating simultaneously to deliver refined commodities like gold, silver, coal and iron ore. It's a five stage process and we've broken it down using GIFs. Exploration...

GEOPHYSICAL METHODS IN EXPLORATION AND .

Thus, deposits of highdensity chromite, hematite, and barite yield gravity highs, whereas deposits of lowdensity halite, weathered kimberlite, and diatomaceous earth yield gravity lows. The gravity method also enables a prediction of the total anomalous mass (ore tonnage) responsible for an anomaly....

Iron Ore Processing for the Blast Furnace

Iron Ore Processing for the Blast Furnace (Courtesy of the National Steel Pellet Company) The following describes operations at the National Steel Pellet Company, an iron ore mining and processing facility located on the Mesabi Iron Range of Minnesota. Creating steel from lowgrade iron ore requires a long process of mining, crushing,...

Mercury Mining,Techniques, Mines, Occurence, Processing ...

This excludes largescale, extremely automated mining techniques. The majority of widespread technique of ore recuperation is subversive mining, with conformist drilling and gusting followed by scraping or perfunctory loading into ore cars....

4 Uranium Mining, Processing, and Reclamation | Uranium ...

T his chapter outlines the basic steps involved in mining, processing, and reclamation that might be suitable for uranium ore deposits in the Commonwealth of ia. For uranium ore deposits, the choice of mining methods and processing options is very depositspecific and dependent on many variables such as the quality and quantity of the ore, the shape and depth of the ore deposit, site ......

Mining method selection by multiple criteria decision ...

historical factors. The appropriate mining method is the method which is technically feasible for the ore geometry and ground conditions, while also being a lowcost operation. This means that the best mining method is the one which presents the cheapest problem. There is no single appropriate mining method for a deposit. Usually two or more...

extracting and refining methods used for mining iron ore ...

extracting and refining methods used for mining iron ore is a leading global manufacturer of crushing and milling equipment (extracting and refining methods used for mining iron ore), also supply individual (extracting and refining methods used for mining iron ore...) crushers and mills as well as spare parts of them....

Mining and Refining – Process World Aluminium

Aluminium is the most abundant metal in the earth's crust. On some surface deposits there is no overburden, and on others, the bauxite may be covered by up to 20 metres of rock and clay. On average, overburden thickness is around 2 metres. The bauxite layer beneath the overburden is broken up using methods such a blasting,......

Mining LKAB

Ore is extracted from LKAB's surface mines by means of bench mining. The method is based on mining the ore in descending levels through drilling and blasting. The thickness of the slabs, known as the bench height, is 15 metres, and the slabs are worked downwards. Bench mining is an effective and well established mining method, which allows maximum extraction from the rock with a high degree ....