cement process engineers cement kiln process

process of operating a cement mill

Manufacturing process . All about Cement Cement : Lafarge The cement manufacturing process starts from the mining of raw materials that ... A lizenithne quarry is ....

Sample Cement Process Engineer Resume | How to Write ...

Joey Spray. 1461 Desert Broom Court. Hackensack, NJ 7601 (555) [email] Objective Searching for an opportunity to improve my skills by obtaining a Cement Process Engineer position with a established company.. Summary of Qualifications: Highly experienced in process engineering within maintenance, operations and plant engineering environments...

20 Best cement engineer jobs (Hiring Now!) | SimplyHired

Cement Process Engineer. Roanoke Cement Company. Extensive knowledge of cement industry, rotary cement kiln and milling operations;......

Alternative Fuels for use in Cement Kilns: Process Impact ...

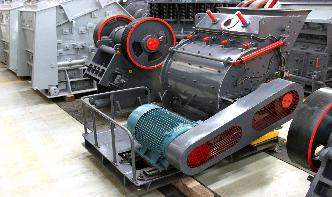

The cement manufacturing process basically includes quarry, raw material preparation, preheating of raw material, kiln, clinker cooling, grinding, storage and dispatch. A schematic diagram of the ......

Cement Extraction and processing |

Manufacture of cement. The three processes of manufacture are known as the wet, dry, and semidry processes and are so termed when the raw materials are ground wet and fed to the kiln as a slurry, ground dry and fed as a dry powder, or ground dry and then moistened to form nodules that are fed to ....

Cement Manufacturer's Handbook Chemical Publishing

This unique handbook contains the most essential engineering formulas used in the cement manufacturing process. All formulas are presented in both English and metric systems of units. Examples are given to familiarize the reader with the usefulness of these formulas. The book can be used as a text manual for courses in cement technology,...

ppt on reactions in cement process BINQ Mining

Cement manufacturing – components of a cement plant. Cement manufacturing process – components of a cement plant from quarry to kiln to cement mill. . including reactions in the kiln, see the ' Clinker ' pages. »More detailed...

Cement engineering design | LCDRI CN

cement engineering design Engineering research results A process for treating domestic garbage by using a cement clinker production line, so that the cement kiln can treat domestic garbage without affecting the production of cement clinker, and can be adapted to the kiln system to treat domestic garbage by slightly modifying the existing clinker production line....

USA Process for high free lime content in cement ...

A source of free lime is introduced into a cooling zone of a cement kiln in an amount to elevate the free lime content to a content of to %, by weight. This addition is made without altering the normal or standard process operating parameters of the kiln for cement clinker production. The free lime content of to %, by weight, provides advantageous characteristics in cement ......

Process Mechanical expertise Fives in Cement | Minerals

Fives' expertise also ensures the reliability of conventional equipment such as the FCB kiln or the FCB BMill. Mechanical computing used to reach optimization Inhouse software developed to establish the sizing of heavy mechanical parts of proprietary equipment....

Unprecedented kiln performance using advanced process control

With the help of FL ECS/ProcessExpert advanced process control system, the Cimentas Izmir plant can now be very proud of its run factor of 94% one of the highest run factors in the world for a cement kiln application. Before the ECS/ProcessExpert system was implemented, on average tph clinker was produced....

Portland cement Manufacturing process Mining Equipment

Portland cement Manufacturing process. Portland cement is made by heating raw materials rich in oxides of silicon, calcium, aluminium and iron to temperatures of around 1200 – 1400oC. The chemical reactions that occur within the partially molten mass result from the formation of the four main cement ....

The Cement Manufacturing Process | Process Systems ...

Aug 15, 2017· The Cement Manufacturing Process Cement is a finely ground powder which, when mixed with water, forms a hardening paste of calcium silicate hydrates and calcium aluminate hydrates. Cement is used in mortar (to bind together bricks or stones) and concrete (bulk rocklike building material made from cement, aggregate, sand, and water)....

Process problems trouble shooting in cement kiln

Jan 15, 2016· Process problems trouble shooting in cement kiln 1. RNB CEMENTS (P) LIMITED DEPARTMENT PROCESS Presented By Akshay Kumar Si DGM (Process)01/15/16 1 2. 01/15/16 2 3. WHAT ARE THE MAIN PROCESS PROBLEMS IN CEMENT PLANT?...

Three Quick Tips For Manufacturing Of Cement. – Free ...

Oct 03, 2017· Manufacturing Of Cement. Manufacturing Of Cement. by any one of the two methods : (i) Dry process, and (ii) Wet process. In both these processes the three distinct operations of (a) Mixing, Ball mill (b) Burning, Rotary kiln and (c) Grinding are carried out. 1. Dry process....

Craig Wahlquist Process Engineer Central Plains Cement ...

PyroProcess Manager Giant Cement Company January 2014 – August 2015 1 year 8 months. Harleyville, South Carolina. I was responsible for maintaining optimum operation of the Kiln....

Process Technology of Cement Manufacture VDZ

I Process Technology of Cement Manufacture 25 Process Technology of Cement Manufacture I Process engineering research aims primarily at optimising the energy consumption and use of manpower in cement manufacture as well as the quality and uniformity of the cement, and at reducing emissions without compromising economic efficiency. The...

Cement Process Control and Systems | Schneider Electric

Schneider's Cement Production Optimization Solution helps cement producers monitor, control, and identify process inefficiencies and thereby improve plant and energy efficiency. This video shows the solution in action at the Quzhai Cement plant in China, with customer feedback on the value of the solution to their business....

What is the production of cement process

The cement industry is second only to electricity generation for emitting carbon dioxide. 50% comes from the process and 40% comes from burning fuel in transport and production. Every 1000 tons of ......

Experts in Cement Kiln Process Training. Cement Process

Experts in Cement Kiln Process Training. Typical 3 week training course. Courses can be designed to suit operators utility personnel....

Chemical engineer. Production Manager/ Process engineer in ...

Production Manager/ Process engineer in cement/lime resume in Mississauga, ON, Canada January 2010 : cement, refinery, mill, chemical engineering, process engineer, engineer, commissioning, plant manager, chemical, gmp ... • Cement Kiln's Pillard burner and Lime kiln's KFS burner optimization....

Sample Resume for Cement Process Engineer Job Position ...

Take responsibility for creating the ultimate building block of any building with a cement process engineer job. Industrial engineers, including cement process engineers, can earn around 85,880 a year, but you need a great resume to stand out in the application pool and eventually land the job.. A degree in engineering or chemistry is usually required....

Dry process | cement |

manufacturing of cement. In cement: Manufacture of cement .are known as the wet, dry, and semidry processes and are so termed when the raw materials are ground wet and fed to the kiln as a slurry, ground dry and fed as a dry powder, or ground dry and then moistened to form nodules that are fed to the.. Read More....

Cement Manufacturing Process | Civil Engineering Forum

Cement is a hydraulic binder, it hardens when water is added to cement powder. Joseph Aspdin, a Leeds Builder and bricklayer had invented the Portland cement in 1824. In this process,Aspdin mixed and ground hard limestone and finely divided clay into the form of slurry and calcined it in a furnace similar to a lime kiln,till carbon di ......