coal coal froth flotation

coal plant coal flotation BINQ Mining

Jan 22, 2013· coal flotation plant supplier in Australia,column flotation design. SBM's core business i s process equipment supply, metal lurgical testing and process consulting. Basic services range f rom evaluat ive studies through equipment ....

Coal Washing | Density Separation | Froth Flotation | RPM ...

Coal washing is accomplished by one of two major processes, by density separation or by froth flotation. Both processes depend on the fact that the particles of which a coal sample are made have different densities....

Coal Flotation and Fine Coal Utilization, Volume 14 1st ...

This is the first monograph on the processing of fine coal which recognizes that all unit operations that handle fine coal depend on coal surface properties, and which in one single volume provides a comprehensive introduction to coal surface chemistry, using it rigorously in treating coal flotation fundamentals and engineering, fine coal manipulation, pelletization and briquetting, and coalwater ....

Method for the froth flotation of coal The Dow Chemical ...

Sep 13, 1988· The froth flotation of coal is conducted in the presence of a conditioner of an oxygen containing compound of the formula: R 1OR 2) n (I). wherein R 1 and each R 2 are independently saturated hydrocarbyls and n is from 1 to about 3....

Froth Flotation Cells Coal Beneficiation Parnaby Cyclones

Operation. Fine coal can be separated from shale and other waste by the process of froth flotation. The coal is made water repellent by the addition of a reagent such as oil, so that when a suspension of coal is agitated with air it sticks to the air bubbles and floats to the surface, collecting as froth. Shale and other waste are not wetted by......

Spargers for Froth Flotation | Coal Age

SlamJet and CavTube spargers are designed, engineered and optimized for each coal and mineral processing application. The CPT SlamJet sparger can be removed without draining the separator or shutting down the system. This unit automatically shuts off in the event of a supply gas failure to prevent process fluid from backing up into the gas line....

Effect of water chemistry on froth stability and coal ...

In this study, the coal flotation was performed in the solutions MgCl2, NaCl, and NaClO3....

AN INPLANT EVALUATION OF FROTH WASHING ON .

AN INPLANT EVALUATION OF FROTH WASHING ON CONVENTIONAL FLOTATION CELLS FOR COAL Timothy Josiah McKeon Thesis submitted to the faculty of the ia Polytechnic Institute and State University in partial fulfillment of the requirements for the degree of MASTERS OF SCIENCE In Mining and Minerals Engineering Luttrell, Chair Yoon...

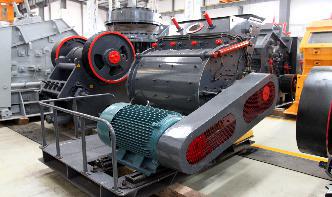

coal froth flotation machine

Coal froth flotation machine products are most popular in Southeast Asia, Africa, and North America. You can ensure product safety by selecting from certified suppliers, including 47 with Other, 7 with ISO9001, and 3 with OHSAS18001 certification....

Fundamental froth flotation research maximises mineral ...

Aug 17, 2018· In mineral processing, froth flotation is a major separation process used in the beneficiation of mineral particles and occurs when crushed and groundup ore is treated with a reagent to make the mineral surface water repellent and causes the valuable mineral to stick to the bubbles....

USA Promoters for froth flotation of coal ...

In a froth flotation process wherein solid coal particles are selectively separated under coal froth flotation conditions as the froth phase from remaining solid feed ash particles as an aqueous phase in the presence of a coal particle collector and a frother, the improvement characterized by the addition of an effective proportion of a hydrophobic, nonionic promoter comprising a C 10C 30 fatty acid; an ....

Coal Flotation | SpringerLink

Coal flotation is characterized by the chemical and petrographical composition of coal and its rank. In addition, size and sp . gr. of coal particles, pulp density, rate and uniformity of feed, conditioning, type of reagents, pH, presence of clay and type of flotation machines are the other variables which influence the coal flotation....

Beneficiatipon of Chamalang Coal by Froath Floatation

Cleaning of Chamalang coal samples was carried out using froth flotation technique. The kerosene oil was used as a collector. Chamalang coal belongs to lignite to sub bituminous coal category. The constituents of the Chamalang coal sample such as inherent moisture, ash, ....

Froth flotation process of coal washing

Froth flotation process of coal washing Products. As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, Froth flotation process of coal washing, quarry, aggregate, and different kinds of minerals....

Froth Flotation | Download eBook PDF/EPUB

Description : th The technology of froth flotation, invented in the early 20 century was first used for the concentration of sulfide minerals. Since then it has been applied for the processing of many nonsulfide ores as weIl, including oxides, carbonates, silicates, soluble minerals like halite and sylvite and energy minerals like coal and bitumen....

Coal preparation Higher rank coal Froth flotation ...

The froth flotation of coal has widespread application for the concentration and separation of fine coal particles from mineral matter. The response of coal to the froth flotation process is initially measured by a laboratory scale test. Although the principles used for the laboratory tests are generally similar,...

Coal Froth Flotation Equipment Sale Stone Crushing Machine

Coal Processing Equipment for Sale Coal preparation plant with handling . to a distribution box and then pumped to the froth flotation circuit. The raw coarse coal is . Gold Froth Flotation Machine with ISO 9001 HOT SALE – ....

BUSTING THE MYTHS OF FLOTATION IN THE .

Coal flotation circuits will be compared to those employed in modern base metal flowsheet designs to address the perception that the current designs used in the industry are inadequate and more sophisticated circuits should be developed Plant data gathered from ....

EFFECT OF KEY VARIABLES ON COAL CLEANING BY .

Coal, in India and Worldwide, is cleaned predominantly by dense medium separations and jigging. But when it comes to cleaning of fine coals such as mine dust, slack coal, washing rejects and slurries, froth flotation method of coal cleaning has better efficiency and handling. In...

coal flotation

coal flotation with ibs/oil froth Dried coal is fed into the lock hopper where it is pressurized using air. Water and the flotation media used are fed into the mixing chamber and are pressurized to the same pressure as the coal....

HOW TO GET THE MOST FROM YOUR CHPP FLOTATION .

Froth flotation is used in many Australian coal handling and preparation plants (CHPP) for upgrading fine and ultrafine coal. Although coal and sulphide ore flotation are very different, there are also some useful similarities. Table 1: Typical operating data for various flotation applications....

Flotation at Goedehoop Colliery SAIMM

Testwork at Goedehoop Colliery showed that fine coal, essentially –150 microns can be successfully beneficiated using froth flotation. Both conventional and column flotation were tested. It was found that the traditional stirred tank type of flotation machines used in conventional flotation produced the best recovery of fine coal. After...