cement raw mill principles

design work in vertical cement mill

The OK™ mill the most reliable and efficient mill for raw and . Jun 26, 2017 The OK mill has been FL's standard cement vertical roller mill (VRM) since 1993. In 2017, FL also introduced the OK raw mill for raw material grinding, designed with the same proven design as the OK cement mill....

Grinding Cement Principles

Cement production line, Cement making production line. 1, dry type cement production process: drying and grinding the raw materials at the same time, or drying the ... Get Price grinding principles in ball mill ....

john Rawls Theory of Justice the original position and ...

(3) their capacity to be reasonable and to have a sense of justice. These are the three "higherorder interests" the parties to Rawls's original position aim to promote in their agreement on principles of justice. The three higherorder interests provide the basis for Rawls's account of primary social goods...

Cement Wikipedia

Cement is seldom used on its own, but rather to bind sand and gravel together. Cement mixed with fine aggregate produces mortar for masonry, or with sand and gravel, produces concrete. Cement is the most widely used material in existence and is only ....

principle of grinding cement

principle of grinding cement . Cement additives principle of grinding cement,Cement additives is being used by the cement plants to improve productivity as well as improvement in cement and concrete, Working principles of grinding aids 2 roller press grinding theory in cement ZME Quarry Crusher, roller press grinding theory in cement cement silo ....

Elastomer (Rubber) Bonding Principles | LORD Corp

Blends of two or more gumstocks (, NRSBR mixtures, NBR millmixed with IR) are chosen so the most desirable features or properties of each component are available. Blends are also selected in an effort to improve raw material economics, without compromising finished part quality....

Cement Process Energy Saving ECCJ

Cement Process Energy Saving October, 2006 The Energy Conservation Center, Japan Tro Kawase. Laos 2 Water Layout of one Japanese cement factory Waste tire yard Coal yard Electrostatic Precipitator Raw mill crusher SP calciner Rotary kiln Cement silo Shipping pier Birdeye View of Japanese Cement Factory ... Cement mill Admix ......

THE MAIN IDEA OFTHE THEORY OFJUSTICE

the principles of justice as fairness comes as close as a society can to being a voluntary scheme, for it meets the principles which free and equal persons would assent to under circumstances that are fair. In this sense its members are autonomous and the obligations they recognize selfimposed....

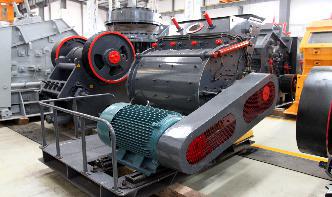

working principle of raw mill kiln plant

Kiln And Raw Mill 33 Address Of Mesto Crusher. kiln and raw mills are dedusted in an ESP . flow chart – cementturnkey working principle of raw mill kiln plant | india crusher Home » stone crusher » working principle of raw mill ......

wikipedia org wiki cement raw mill

Raw Cement Mill Operation China gurgaonprojectsorg, Cement mill Wikipedia, the A cement mill (or finish mill in These have been used for many years for the less exacting raw with the cement finished in a single .......

raw mill working principle

Handles all types of raw material . Working principle The ATOX raw mill uses pressure and shear generated between the rollers and the... Get Price. Study of Processing and Machinery in Cement Industry. ... Apr 19, 2016 ... working of vertical raw mill in cement plant .... working principle of vertical roller mill used in cement production ......

Cement grinding Vertical roller mills versus ball mills

cement industry the ball mill was really an epochmaking breakthrough as for almost 80 years it was the predominant mill for grinding of raw materials and coal, and still today is the most used mill for cement grinding. Over the last three decades the vertical roller mill has become the preferred mill for grinding of raw materials....

Vertical mill's working principle in the process flow of ...

Aiming at the cement production status and market demand, Guilin Hong Cheng launches a vertical mill with superior performance. 1. Process flow of cement production. In simple terms, process flow of cement production is the overall process of cement raw materials being processed into cement finished product....

what is the raw mill in cement

material balance around the raw mill in cement. Raw Mill In Cement Plant,Cement Making Plant Hot, A raw mill is the equipment used to grind raw materials into "rawmix" during the manufacture of cement It's mainly used in grinding raw materials and end products in cement . Cement grinding Vertical roller mills versus ball mills...

cement mill working principle diagrammatic

Feb 14, 2016 ... working principles of ball mill working principle of ball mill, ball mill for sale. ... with diagram Coal processing system Machine Working Principle of ... clearly views of ball milling operation new user Next: national cement mill ltd. Chat Now...

Raw material preparation. From the quarry to raw meal ...

Raw material preparation. From the quarry to raw meal feeding into the preheater. A company of Polysius ThyssenKrupp ... raw materials for the cement production process is decided on the basis of ... provide the raw mill with the feed size range it requires....

Cement Controlling hazardous substances Managing ...

Cement and cementbased products can harm the skin in a number of ways. Wet cement is highly alkaline in nature. A serious burn or ulcer can rapidly develop if it is trapped against the skin. In extreme cases, these burns may need a skin graft or cause a limb to be amputated. Cement can also cause chemical burns to the eyes....

raw mill principle

Working Principle Of Raw Mill Working principle of raw mill Working principle of raw mill The raw mill is a key equipment to grind the crushed materials, and the raw mill is widely used in powdermaking production line including Cement, silicate, newtype building material, refractory material, fertilizer, Ore Dressing of ferrous metal and non,...

HeidelbergCement Group

HeidelbergCement is the number 1 in aggregates production, number 2 in cement, and number 3 in readymixed concrete. We have 740 mining sites, 3,000 plants worldwide, limestone reserves for more than 90 years, and aggregates reserves for more than 60 ....

PROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL .

4. MILL LOAD CONTROL LATEST CONCEPT FOR CEMENT MILL OPTIMISATION Concept M/s Holderbank Engineering, Canada has developed a control strategy for ball mills which can maintain a mill production near optimum, with little operator intervention. The main principle of ....

Ball Mills

In all ore dressing and milling Operations, including flotation, cyanidation, gravity concentration, and amalgamation, the Working Principle is to crush and grind, often with rob mill ball mills, the ore in order to liberate the minerals. In the chemical and process industries, grinding is an important step in preparing raw materials for subsequent treatment....