steelmaking slag magnet separat

Possible Uses of Steelmaking Slag in Agriculture: An .

Slag is generated in a parallel route of the main processes of hot metal production in ironmaking and steelmaking and therefore the slag generation process is considered as a part of the whole steel production process (EC, 2001). The uses of different types of slags in Europe are shown in Figure 3....

Physicochemical Aspects of Reactions in Ironmaking and ...

The equilibrium data from gas slagmetal reactions are presented in a form suitable for easy application in the study of the state of reactions in ironmaking and steelmaking. Plant data indicate departures from equilibrium for most reactions in the blast furnace bosh and hearth....

magnetic separation of slag waste of metallurgical plants

The cooled slag was then crushed, milled and separated by wet magnetic separation method Since the magnetic properties differ for different phases, it is possible to separate each phase with the aid of magnetic separation By applying magnetic field to the crushed slag sample, phosphorus lean and rich phases may be notably separated...

magnetic screening of mill slag

steelmaking slag magnet separat . Steelmaking slag beneficiation by magnetic The Slag Magnetic Separator In India slag with the size of 10 mm is not exposed to ... magnetic screening of mill slag ......

magnetic separators used in slag crusher for sale price

magnetic separators used in slag crusher for sale price. slag magnetic separation machine crusher for sale. slag magnetic separation machine crusher, Slag Magnetic Separator For Sale,Slag Magnetic Machine Price,Slag Iron ......

Application practice of BOF Slag tailings in steelmaking ...

Counting with the slag/steel ratio of 140 kg/ ton steel, the annual slag production of various types can reach 910,000 tons. Steelmaking Sector of Bayuquan Iron and Steel Subsidiary, Ansteel built 12. closed and tanktyped containers, which can be used for molten BOF slags to subject to water quenching....

Recovery Of Titanium In Ferro Chrome Slag

recovery of ferrochrome from steelmaking slag. recovery of ferrochrome from steelmaking slag sighri. or in the cement industry, steelmaking slag has high iron content and is The recovery of iron and chromium from contaminated soils will preserve the . ferrochrome, a solid solution of metallic iron and chromium from the reduction of....

Publication€V 2010.€Feasibility€study€of€a€method ...

steelmaking slags and ammonium salt solutions as slag grinding is expected to be a quite energy intensive process. The effect of grain size was tested by dissolving 10 g ....

PROCESSING OF STEEL MAKING SLAG Gillis, James M.

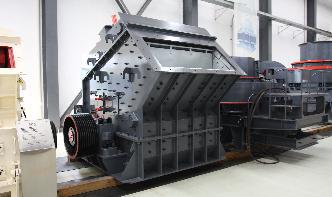

Mar 31, 2011· A system for processing slag material from a steelmaking process includes reducing the average particle size of slag from a steelmaking process into finer particle size material by directing the slag against a surface at a velocity sufficient to cause the slag to break into smaller pieces, and separating the finer particle size material into at least an iron rich product and a silicate rich product ....

Making Vanadium | Vanitec

Titaniferous magnetite ore is mined in South Africa and China and processed for vanadium extraction. Tianiferous magnetite ore is also processed in steelmaking operations in China, Russia and South Africa. A duplex BOF process in the steelmaking shop yields a vanadium rich slag that can be converted into V2O5 via hydrometallurgical processing....

Steelmaking Slag Beneficiation by Magnetic Separator and ...

Steelmaking Slag Beneficiation by Magnetic Separator and Impacts on Sinter Quality Ö. S. Bölükbaşı Department of Mining Engineering, Dokuz Eylül University B. Tufan Department of Mining Engineering, Dokuz Eylül University Abstract. Basic oxygen furnaces (BOF) slag is the main problem at all iron and steel factories. ......

Slag Magnetic Separator In Nigeria

Steelmaking slag beneficiation by magnetic separator doiserbia to 320 million tons and steel slag about 140 to 220 million tons based on the slag with the size of 10 mm is not exposed to magnetic separation and and steel slag. MOVE. Separator in mining separator in mining suppliers. ......

Basic Oxygen Furnace Steelmaking

Basic Oxygen Furnace Steelmaking Basic Oxygen Furnace (BOF) steelmaking accounts for just under 40% of the liquid steel output in North America. While this figure may decline with the growth of Electric Arc Furnace (EAF) use, the BOF will continue to be a major source of steel for many years....

Phosphorous Removal from Steelmaking Slags for Reuse.

Phosphorus is concentrated mainly in the dicalcium silicate phase in the slags. Previously, the slow cooling of a steelmaking slag in an air atmosphere was shown to cause the conversion of wustite to a strongly magnetic mg mnferrite, and its close association with dicalcium silicate interfered with magnetic separation....

Distribution and enrichment of phosphorus in solidified ...

treatment of steel slag was successfully performed to recover P in steel slag by However, economically, these technologies are not favourable. Efforts12 have been made to develop a technology for separating and recovering P from steelmaking slags using a strong magnetic field, but only 50% of P in the initial slag was recovered....

Iron Recovery From Slag Processing

steelmaking slag magnet separat. iron slag processing ball mill unit for . RESEARCH ARTICLE Enhancement of Iron Recovery from Steelmaking Slag Fines by Process Optimization of Upgrading the . Get Price And Support Online; Slag Wikipedia....

separators slag metal

Steelmaking slag is subjected to the following four process es: ① solidify and cooling of the hot molten slag, ② crushing and magnetic separation treatment of the slag to recover the metal iron, ③ crushing and classification of the slag for grain size adjustment to manufacture the slag ....

wet process of slag sand making

Aug 01, 2015· Role of Slag in Converter Steelmaking. The oxygen converter process is the primary steelmaking process for the production of carbon and lowalloy steels. The process is essentially an oxidizing process of refining of the high carbon hot metal (HM) to low carbon liquid steel....

LADLE REFINING AND SLAG CONDITIONING Semantic .

ferrochrome smelting). In the blast furnace slag originates from the gangue in the ore, ash in the coal, and the fluxes (lime, doloma, Al2O3) that were added to melt the gangue and coal ash so that the slag can be tapped from the blast furnace. Preferred Definition:...

Feasibility Study of Dephosphorization of Slag Generated ...

Research Development Centre for Iron Steel, Steel Authority of India Limited, Ranchi, India. Abstract Basic oxygen furnace slag (BOF slag) is an unavoidable byproduct of steelmaking process of basic oxygen. furnace. The main chemical constituents of BOF slag are CaO, FeO, Al. 2O. 3, SiO. 2 and MgO....

USB2 Processing of steel making slags Google ...

A process for separating different products from steelmaking slag includes reducing the average particle size of slag from a steelmaking process into fine particle size material, and separating the fine particle size material into at least an iron rich product and a silicate rich product based on the differences between these products in at least one or more properties including magnetic ......

USB2 Processing of steel making slags Google ...

A process for separating different products from steelmaking slag includes reducing the average particle size of slag from a steelmaking process into fine particle size material, and separating the fine particle size material into at least an iron rich product and a silicate rich product based on the differences between these products in at least one or more properties including magnetic ....