ball weight effect in ball mill

A study on the effect of ball diameter on breakage ...

Effect of ball diameter has been studied on the limestone and clinker samples under batch grinding conditions based on a kinetic model. Firstly, eight different monosize fractions between mm and mm formed by a √2 sieve...

The Processes of Matching the Proper Grinding Balls for ...

The grinding ball is a material grinding media of ball mill and coal mill. Its' function is as an important component of ball mill under grinding and cutting effect brought by the friction between grinding balls and,let's talk about the processes of matching the proper grinding balls for ball ....

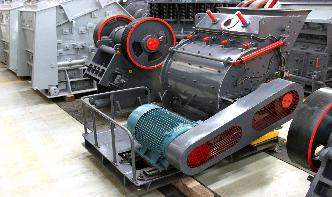

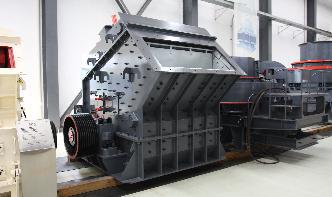

What is a ball mill? What are its uses and advantages? Quora

The ball mill is a key equipment to grind the crushed materials, and the ball mill is widely used in powder making production line including cement, silicate, newtype building material, refractory material, fertilizer, ore dressing of ferrous metal and nonferrous metal, glass ceramics, etc, and the ball mill can grind various ores and other ......

Ball Milling Treatment of Black Dross for Selective ...

a vessel with 40 g agate balls (a ball of 6 mm in diameter) with the weight ratio of ball/black dross of 5:1 and were then milled for 1, 3, 5, 7, and 10 h at 400 rpm. In the case of the effect of ball mill speed, the samples were milled at 250, 400, 550, and 700 rpm for 1 h at the ball to a powder weight ....

Weight Of M S Ball In Ball Mill

calculating ball weight in a ball mill benitomedia. Effects of Ball Milling and Sintering on Alumina UWM Digital . Multiple samples of pure alumina, weight percent boron, and weight percent boron are batched and processed in a ball mill for different time intervals. . Get Support Online...

Patterson Industries Ball Pebble Mills

Types TD and TDJ Ball and Pebble Mills. Split and easily detached, they are equipped with a special gasket held in tension by a special springloaded device, assuring a dusttight seal between mill and housing when the Pebble Mill is in operation. Elevation on steel subbases or ....

THE EFFECT OF BALL MILL OPERATING PARAMETERS .

THE EFFECT OF BALL MILL OPERATING PARAMETERS ON MINERAL LIBERATION by Hector E. Rojas Dissertation submitted to the Faculty of the ia Polytechnic Institute and State University in partial fulfillment of the requirements for the degree of Masters of Science in Mining and Minerals Engineering APPROVED: G. T. Adel, Chairman I R. E./Yoon ......

Praticle Size Reduction in the Ball Mill: Drug Development ...

However, the most critical factor affecting the milling process, was the weight and nature of the grinding medium. It was found that heavy porcelain was more efficient than glass spheres and that the optimum weight was ; the weight required to approximately half fill the ball mill....

The influence of mill speed and pulp density on the ...

THE INFLUENCE OF MILL SPEED AND PULP DENSITY ON THE GRINDING EFFICIENCY 93 Graph 5. Pulp charge and ball charge angles 205 200 195 190 185 180 175 170 165 media angle pulp angle 68 70 72 74 76 78 % solids Angle The pulp volume, on the other hand, increases linearly...

Cyclone Effects In Ball Mill

cyclone effects in ball mill Coal Surface Mining SAMAC . cyclone effects in ball mill Description : STARTLING EFFECT OF BALL SCATS REMOVAL ON SAG MILL . ) mill, typical of the majority of SAG mills in the South African ... ball weight effect in ball mill . cyclone effects in ball mill ......

henan bailing ball mill

Before manufacture ball mill machine, making a thorough research into ball mill structure, ball mill working principle, and various ball mill technology parameters then working out a ball mill design scheme is necessary. Besides the theory, the practical ball mill use must be taken into consideration....

Effects of Ball Milling and Sintering on Alumina and ...

Multiple samples of pure alumina, weight percent boron, and weight percent boron are batched and processed in a ball mill for different time intervals. These samples are then characterized to observe the structure and properties of the samples after milling but before sintering. Pellets are dry pressed from the milled powders, sintered at...

Highenergy ball milling technique for ZnO nanoparticles ...

Apr 29, 2011· The mixture ratio of steel balls and ZnO powders was around 15:1 by weight percent. The milled materials were used directly with no added milling media. Five balls were kept in each cell along with 10 g of the sample powder....

MILLS Planetary Ball Mill MRCLAB

MRC Planetary Ball Mill have two superimposed movement move the grinding jars, Like in a planetary system the grinding jar rotates on a orbit around the center, This rotational movements is the selfrotation of the grinding container superimposed. The result centrifugal and acting acceleration forces lead to strong grinding effects ....

Simulation of Size Reduction in Ball Mills and DEM

The mill (with 30 cm in diameter and 30 cm in length) and the test conditions are standardized, with a maximum ball size of 40 mm and an ore top size of mm. With less than 300 balls, it poses no challenge in running the simulations, if only grinding media are included. For such a small mill, one could also include the ore or powder charge....

Temperature progression in a mixer ball mill | SpringerLink

Apr 22, 2016· For example, it was shown that milling in a mixer ball mill (MBM) for 10 min with two milling balls in a 10 ml beaker raised the temperature from 25 to 30 °C, and Colacino and coworkers measured a temperature increase of approximately 14 K after 30 ....

Effect Of Ball Top Size Ball Mill

effect of ball top size ball mill . effect of ball top size ball mill libertyedu. effect of ball size in ball mill rivertouchresort. The optimal ball diameter in a mill. grinding quartz and copper ore. Chat With Sales. effect of ball size in ball millprakashpublicschool. Get Price; Ball Size Effect On Grinding Mill . Ball Size Effect On Grinding Mill ....

The operating principle of the ball mill

The operating principle of the ball mill consists of following steps. In a continuously operating ball mill, feed material fed through the central hole one of the caps into the drum and moves therealong, being exposed by grinding media. The material grinding occurs during impact falling grinding balls and abrasion the particles between the balls....

effect of ball size in ball mill

effect of ball size in ball mill Calculate and Select Ball Mill Ball Size for Optimum Grinding. In Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill is an important thing for a Mineral Processing Engineer AKA Metallurgist to do....

Effect of Slurry Solids Concentration and Ball Loading on ...

Industrial Ball Mill . The ball mill utilized in the sampling survey has an inside diameter of m and length of m and is run in open circuit. Under normal operating conditions, the mill ball loading is 30% of total mill volume, mill rotational speed is 75% of critical speed, slurry solids concentration is75%, solids feed rate is 330 tph....

BALL MILL METHOD FOR DETERMINING THE .

Combining values from the two systems may result in nonconformance with the standard. 2. Wet Ball Mill machine, consisting of a watertight steel cylinder, closed at one end, with inside dimensions of ± 3 mm ( ± in.) in diameter and ± 3 mm ( ± in.) in length....