exraction of metals

How are nonmetals extracted? Quora

Oct 20, 2016· EXTRACTION OF METALS AND NON METALS Metal ores are formed in the process of ore genesis, and they are extracted through mining. Extraction metallurgy is the practice of removing valuable metals from an ore and refining the extracted raw metals in......

Occurrence of Metals: Metal Ores, Methods of Extraction ...

Extraction of Metals. The occurrence of metals in nature is only a part of the process, these metals also have to be extracted. Metallurgy is the process of extracting metals. The basic step of extracting metals is called concentration of ores. Concentration of Ores. The ores contain a lot of impurities that need to be filtered....

Removing Heavy Metals From Wastewater Bluevantage

Removing Heavy Metals From Wastewater Introduction This manual provides general guidelines on how to remove dissolved metals from wastewaters for discharge to sanitary sewer systems. Each of the various stages or operations of wastewater treatment will be discussed with their role in the metals removal process....

Extraction of Metals | Aluminium Oxide | Aluminium

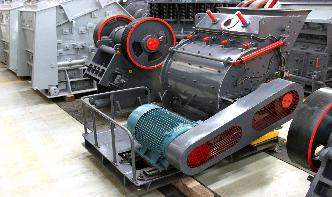

In the production of most metals, four distinct steps are needed to convert ore to refined metal. These steps are: mining, milling, smelting and refining. The total process is called metallurgy....

Metals | Special Issue : Solvent Extraction of Transition ...

Solvent extraction plays an important role in the field of hydrometallurgy and analytical chemistry. Since metal ores are depleting, it is of importance to recover the valuable metals present in secondary resources to meet the demands for the manufacture of advanced materials....

HISTORY OF METALLURGY

The use of fire thus makes possible two significant new steps in the development of metallurgy: the casting of metal, by pouring it into prepared moulds; and the smelting of mineral ores to extract metal. Objects made from smelted copper, from as early as 3800 BC, are known in Iran....

Extraction of sodiumExtraction of sodium by Down's method

EXTRACTION OF SODIUM . On industrial scale sodium metal is extracted by "Down's Process". PRINCIPLE. Down's Process is based on the electrolysis of fused NaCl. CONSTRUCTION OF DOWN'S CELL Down's cell consists of a rectangular container of ....

Extraction of Metals Worksheet EdPlace

Metals such as zinc, nickel, tin, lead and copper need to be heated with carbon (or carbon monoxide) to extract them. The more reactive metals require electrolysis (a techinique involving electricity) to achieve this. Iron, however, is removed in a blast furnace, like the one below:...

Extraction procedures for the determination of heavy ...

Chemical extraction of sediments has proven to be adequate for determining the metal associated with source constituents in sedimentary deposits, but the general aim of many studies involving chemical extraction is the determination of element distribution among different phases of a sediment. Single extractants are usually chosen to evaluate a particular release controlling mechanism such as ....

Extraction of metals SlideShare

Sep 26, 2016· Reactivity series of metals: In chemistry, a reactivity series is an empirical, calculated, and structurally analytical progression of a series of metals, arranged by their "reactivity" from highest to is used to summarize information about the reactions of metals with acids and water, double displacement reactions and the extraction ......

The History Of Metal Extraction by Abbie Williams on Prezi

Gold is a shiny, soft, dense and malleable metal. It was used by the ancient Egyptians for the burial masks of dead pharaohs. Along with Gold, Silver, Copper, Tin, Mercury, Iron and Lead were all ....

What is the best method for extracting heavy metals from ...

The best method for extraction of heavy metals namely Zn, Cu, Fe, Mn, Ni, Cd, Pb etc from plant sample is wet digestion with di acid mixture (HNO 3: HClO 4 ::3:1).Before digestion of plant samples ......

Extraction of Metals from Concentrated Ore: Reduction of ...

First, we must convert the ore to a suitable form. The metals need to be in an oxide form for the reduction process to be easier. Hence the ores are converted to oxides, so it is ideal for reduction. After doing so the ores will undergo reduction, to give us metal. Therefore the two main steps of extraction of metals are, Convert Ores to form oxides...

copper extraction and purification chemguide

making brass. Brass is a copperzinc alloy. Alloying produces a metal harder than either copper or zinc individually. Bronze is another copper alloy this time with tin. coinage. In the UK, as well as the more obvious coppercoloured coins, "silver" coins are also copper alloys this time with nickel. These are known as cupronickel alloys....

Extraction of metals by roasting and reduction processes ...

Only very noble metals such as gold or silver occur in nature in metallic form. Most metals are often contained as oxides, carbonates or sulphides in the ores. Especially the heavy metals are often found as sulphide ores. Importance. In metallurgy, the sulphide ores are roasted to obtain from them sulfur dioxide and the metal, usually as metal oxide....

GCSE Chemistry – Extraction of Metals –

Unreactive metals such as gold are found in the Earth itself. Some metals are found as compounds and require chemical reactions to extract the metal. The process of extraction. Metals that are less reactive than carbon can be extracted from their oxides by reduction (removal of oxygen) with carbon....