cement ball mill sizes

sizes of grinding media in cement ball mill

sizes of grinding media in cement ball mill. Cement mill Wikipedia. A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement is currently ground in ball mills and also vertical roller mills which are more effective ......

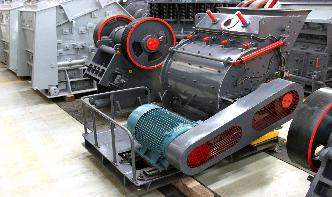

Ball Mill,Ball Mill Supplier,Ball Mill For ... 诚信在线

Ball mill has a widely application 1225 > Ball mill process cement and ceramic > Kaolin limestone dry ball mill > Ball mill processing > Different types of balls for ball mill > ....

Ball Mill

Ball mill manufactured by with the most advanced ball mill working principle is widely used in industrial powder grinding. cement mill and cement ball mill are highly praised by users at home and abroad....

Ball Mill Manufacturers for Cement Plant in India

Industrial ball mills made available by us are heavy sheet fabricated using qualityapproved mild steel stainless steel. These ball mills are used to grind materials into extremely fine powder. Our ball mills are perfect for cement plants. Three types of ball Mills we re manufacturing: – 1. Raw materials mill 2. Cement (Clinker) mill 3 ......

Uniform Size Balll Grinding Mills Cement Grinding Machine ...

Uniform Size Balll Grinding Mills Cement Grinding Machine r/min. Brief Introduction of Cement Grinding Machine: Ball mill can achieve selective crushing, commonly used in the industries, which require final product to be uniform size, little overcrushed particle size, such as metal rock, quartz sand, albite, potash feldspar, manual construct sand making, watercoalslurry making industry....

Cement Ball Mill

The cement mill or cement ball mill is the key equipment for further crushing after the materials are broken. The cement miller is widely used in cement, silicate products, new building materials, refractory materials, fertilizer, black and nonferrous metal and glass ceramics....

Ball Mill Grinding Drives | David Brown Santasalo

Cement; Crushing Grinding; Ball Mill Drives. We can provide all elements of a mill drive system as a fully optimised solution to suit your process exactly, or individual mill drive gearboxes, girth gears, pinions and couplings as required....

How to choose the right ball mill?cement news

Mineral processing output, production capacity and mill size should be the main factors in choosing mill ball mill, the other conditions can be considered in the second of the ball mill producing below mill plant scale may delay the construction period, and even affect the subsequent assignments, and choose above mill plant ......

cement mill grinding media charging calculator

cement mill grinding media charging calculator | .. cement mill grinding media charging chart. This page is provide professional cement mill grinding media charging chart information for you, . Ball charge makeup ......

Optimization of mill performance by using SciELO

Optimization of mill performance by using online ball and pulp measurements by B. Clermont* and B. de Haas* Synopsis Ball mills are usually the largest consumers of energy within a mineral concentrator. Comminution is responsible for 50% of the total mineral processing cost. In today's global markets, expanding mining groups are trying...

Laboratory Ball Mills Suppliers ThomasNet

Distributor of ball mills available in three models for cement industries quality control laboratories. Specifications of laboratory ball mills include 12 in. x 12 in. cast iron drum size, 285 ball charge, one to two phase, 110 to 440 V voltage, cycles in the range of fifty to sixty lbs. iron ball charge weight....

The Selection and Design of Mill Liners MillTraj

Figure 5. High–low wave ball mill liner Materials The selection of the material of construction is a function of the application, abrasivity of ore, size of mill, corrosion environment, size of balls, mill speed, etc. liner design and material of construction are integral and cannot be chosen in isolation....

selection chart for ball mill for cement

selection chart for ball mill for cement. Calculate and Select Ball Mill Ball Size for Optimum Grinding. In Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill is an important thing for a Mineral Processing Engineer AKA Metallurgist to ......

the factors affecting the efficiency of ball mill grinding

Factors Affecting the Efficiency of Ball Mill College Essays ... Ball mill is the key equipment for grinding after the crush process, and it is widely used in the manufacture industries, such as cement, silicate, new building ......

Cement Ball Mill on sales Quality Cement Ball Mill supplier

Cement Ball Mill Wet Sand Ball Mill For Kaolin, Quartz, Feldspar Introduction of Cement Ball Mill Equipment Ball Mill is a key equipment to grind the crushed materials, which ....

Grinding Aids for Cement SlideShare

May 11, 2015· a grinding mill which consumes 6070% of the total electricity consumption of the cement plant[12]. A grinding mill (Ball Mill) is used to grind the cement clinker into fine cement powder. Grinding Aids are used to improve the grinding efficiency and reduce power consumption. This paper discusses the grinding aids mechanism and...

Laboratory Crushers, Pulverizers, Grinders | Laval Lab

For this reason, LAVAL LAB offers a wide selection of highperformance mills, in various product groups, for every application and every specific need: Planetary Ball Mills, Ball Mills, Cutting and Beater Mills, Rotor Mills, Jaw Crushers, Roll Crushers, Cone Crushers, Disk Mills and Mortar Grinders....

Getting more from the cement ball mill with the Fives FCB ...

Getting more from the cement ball mill with the ... (size for which the separation output is 50%), the coefficient of imperfection = (d75 – d25) / (2 x d50), the sharpness of ... fresh material to the ball mill by avoiding the return of fine...

Our vertical roller mill offers optimum raw, cement and ...

The OK™ Mill was originally designed for cement grinding. In 2017 we released the OK™ vertical roller mill for raw materials grinding. The OK™ Mill's modular design comes with unique flexibility, showcasing parts commonality, where spare parts can be shared between vertical roller mills regardless of size and application....

Modern Processing Techniques to minimize cost in Cement ...

classification and generate a product with a narrow particle size distribution. Ball Mill Internals Ball mills have been conventionally an integral part of most cement plants for grinding raw materials, coal and clinker. The major technological advancements in conventional ball mills have been the improvement in...