ballmilling method

MODELING THE SPECIFIC GRINDING ENERGY AND .

power draw from the various methods. zIn the next Figure a comparison is made between the ballmill. power draw values determined from the Denver slide rule, and those calculated from the proposed model. zFrom the distribution of the points around the line of comparison the good agreement of the results received is obvious....

ball milling method for limestone

Soundness testing shall include test methods for autoclave expansion, and popping and pitting of hydrated lime. Application testing shall include test methods for slaking rate of quicklime, dry brightness of pulverized limestone, limestone grindability determination by the laboratory ball mill method, and settling rate of hydrated lime....

The Structural Changes of Hydrothermally Treated Biochar ...

mill, rapidly This may indicate that ballmilling causes only temporary defects in the catalyst that are quickly reformed. The observed ballmiling reactivity was an order of magnitude greater than that observed for the unmilled catalyst, suggesting the potential of ....

Band gapengineered ZnO and Ag/ZnO by ballmilling method ...

In this study, a wet (w) and dry (d) ballmilling method was used to hybridize Ag with ZnO nanoparticles, and their physicochemical properties were examined. Visible light absorption was enhanced and the band gap was engineered by ballmilling and Ag hybridization....

ball milling method for lime stone grinding

ball milling method for lime stone grinding Ball mill Wikipedia. A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium....

StainlessSteel BallMilling Method for Hydro/Deutero ...

A onepot continuousflow method for hydrogen (deuterium) generation and subsequent hydrogenation (deuterogenation) was developed using a stainlesssteel (SUS304)mediated ballmilling approach. SUS304, especially zerovalent Cr and Ni as constituents of the SUS304, and mechanochemical processing played crucial roles in the development of the reactions....

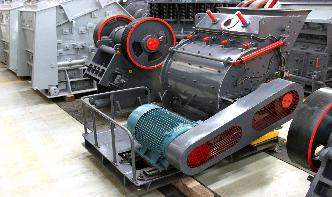

Mineral and Mining Engineering: What is the working ...

Ball Mill Working principle: When the ball mill works, motor and speed reducer transmit torque force to big and small gears of ball mill, so the barrel the barrel rotates, Steel balls or other grinding media in the barrel are lifted t......

Stainless‐Steel Ball‐Milling Method for Hydro‐/Deutero ...

Oct 23, 2015· Abstract. A one‐pot continuous‐flow method for hydrogen (deuterium) generation and subsequent hydrogenation (deuterogenation) was developed using a stainless‐steel (SUS304)‐mediated ball‐milling approach. SUS304, especially zero‐valent Cr and Ni as constituents of the SUS304,......

Preparation of Black Phosphorus by the Mechanical Ball ...

In this paper, red phosphorus successfully turned to black phosphorus by the mechanical ball milling method. The samples were analyzed by the Xray diffraction (XRD) method and by high resolution transmission electron microscopy (HRTEM). The XRD result showed that the black phosphorus obtained had small crystal size and a small, amorphous, broadly diffused peak of red phosphorus....

NANOMATERIALS FROM BALL MILLING University of .

NANOMATERIALS FROM BALL MILLING W. COURTNEY FEB 7, 2006 APPARATUS Mater. Sci. Engin. A 206, 1996, 24 Extended Milling Amorphization Impact Energy of Vibrating Ball Mill Vmax f I* = Mp CHEMICAL REACTIONS DURING BALL MILLING Nanotube Precursor created by ball milling NANOTUBES CREATED FROM EXTENDED MILLING FOLLOWED BY THERMAL ANNEALING OTHER ....

ball mills methods

Nano Ball Milling SlideShare. Dec 15, 2012· Ball milling is a method of production of nano materials. This process is used in producing metallic and ceramic nano materials. These mills are equipped with grinding media composed of wolfram carbide or steel....

Ultrafast Synthesis of NiMOF in One Minute by Ball Milling

Abstract: A mechanical ball milling method for ultrafast synthesis of a nickelbased metal organic framework (NiMOF) has been proposed. The NiMOF was successfully synthesized in merely one minute without any solvent, additives, or preliminary preparation. The effect of milling time,...

Process Parameters Optimization of Silica Sand ...

Experiments are designed using Taguchi method to find the optimum parameters for silica sand nanoparticles production using low speed ball milling. Orthogonal array and signaltonoise ratio are applied to study performance characteristics of machining parameters which are the ball to powder weight ratio, volume of milling jar, and rotation speed....

Study of the use of vertical stirred ball milling as ...

/ Study of the use of vertical stirred ball milling as method to enhance the dissolution of copper from chalcopyrite. IMPC 2018 29th International Mineral Processing Congress. Canadian Institute of Mining, Metallurgy and Petroleum, 2019. pp. ...

Ball Milling Equipment Shimpo Ceramics

Ball Milling Equipment » Our Products. SHIMPO PTA Ball Mills. Ball mills have been used for decades to grind and mix materials used in the ceramic industry. SHIMPO's heavyduty ball milling machines enable very precise milling, in porcelain jars, even for relatively tough materials, wet or dry....