dry process gold recovery

Extracting Gold | HowStuffWorks

Leaching dissolves the gold out of the ore using a chemical solvent. The most common solvent is cyanide, which must be combined with oxygen in a process known as carboninpulp. As the cyanide and oxygen react chemically, gold in the pulp dissolves. When workers introduce small carbon grains to the tank, the gold adheres to the carbon....

Artisanal and SmallScale Gold Mining Without Mercury ...

Chemical leaching makes use of the chemical properties of gold to leach it from ore, concentrate, or tailings. This process is mostly used in large scale mining operations but has been increasingly adopted in small scale mining because of its high gold recovery rate and low cost....

Recover Gold From Computer Parts | Extract Gold From ...

Nitric process or CN process can be used to remove gold from gold plated/polished pins and connectors. From CPUs we can recover gold through aqua regia. Pyrolysis and hydrometallurgy are used for gold recovery from computer chips. Our methods of gold recovery from computer parts are safe and environment friendly....

Demonstration of the CESL Gold Process Teck

concentrates. The CESL Gold Process is fed leach residue produced from the CESL Copper Process and uses pressure cyanidation to increase the kinetics of gold and silver leaching, as well as cyanide recovery to recover copper and reduce cyanide consumption, allowing for economic recovery of precious metals....

Gold recovery increase in CIL circuit Home Pionera

Gold recovery increase in CIL circuit. The benefit of PIONERA BioPolymer is also observed in the Merrill Crowe process. A recent plant trial with an Asian gold mine showed the below results. In addition, the grinding throughput also increased about 9% as the solid content in the feed slurry could be increased from 38% to 40% without loosing recovery....

Gold Cyanide Leaching Process Outotec

Outotec® Cyanide Leaching Process. Achieve optimal gold recovery with minimal impact on the environment. The Outotec cyanide leaching process enables sustainable and costeffective gold recovery. Meets the environmental limits of operation with a sustainable cyanide leaching process. Comes from one supplier, responsible for the whole package....

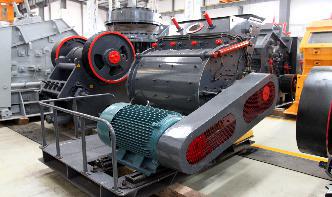

Gold Mining Equipment | eBay

RP4 can process up to 300 lbs. of black sand magnetite or pulverized rock with little or no losses. Uses ½hp, 1725 RPM, 115V,, 60Hertz, 980 Watts Motor. DC36 Impact rock crusher grinding milling gold mining equipment machine jaw ball...

Cornstarch Replaces Cyanide In Gold Extraction | Popular ...

May 14, 2013· Cornstarch Replaces Cyanide In Clean New Gold Extraction Method. Bound up in consumer electronics, jewelry and the ores that it comes from, gold is difficult to extract, and most modern processes do it with a highly toxic combination of cyanide salts. The cyanide leaches the gold out, but the cyanide can seep into the ground, causing environmental problems and posing threats ....

Where to find gold DesertUSA

The Southwest is full of promising places to look for some gold. In the southern half of California you can find good streams to work on public lands in that area west of Lake Tahoe, including Placer, El Dorado, Amador and Calaveras counties. Farther south, down toward Death Valley, you can drive ......

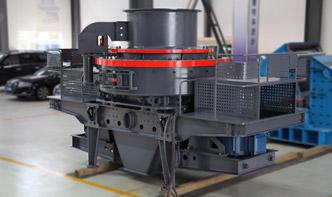

Dry Gold Mining Recovery Equipment

Dry Gold Mining Recovery Equipment. ... Save gold prospecting dry washer to get email alerts and updates on your sponsored sponsored gold dry washer plans diy sluice box gold mining prospecting equipment brand new 999 buy it now free shipping gold dry washer plans diy slui. MOVE. Appropriate process technologies....

Use in Mining | International Cyanide Management Code ...

Ore Preparation. Ores that contain gold and/or silver associated with sulfide or carbonaceous minerals require additional treatment, other than size reduction, prior to metals recovery. The recovery from sulfide ore is poor because the cyanide preferentially leaches the ....

Extremely Fine Gold Recovery Gold Recovery Methods ...

Apr 14, 2015· Geowizard. The process of recovery is a process that continually upgrades the purity through a process of concentration. A sluice box recovers gold as a concentrate which has greater gold content. Recovery is a process of eliminating nongold products from gold. Gravity methods rely on separation based on mass....

dry gold recovery plant

Gold and Silver Plant The operation of the plant was performed through 8 main processes; crushing, grinding, gravity recovery, Gekko plant, CCD circuit, Merrill Crowe, refinery and finally a Lm filter plant was installed for dry stack tailings in 2013....

Gold Process Development Mintek

Gold Process Development Mintek's gold process developMent prograMMe provides a quick and costeffective method of ensuring that gold recovery operations perform at their optimum level. testwork may be carried out at both laboratory and pilotplant scales, supported by wellproven computer...

Free Gold | Gekko

Free Gold Recovery. After crushing ore clumps to a manageable size of 20mm or less, via the Python or other crushing circuit, Gekko offers a range of free gold recovery options.. At the coarse 350 micron 20mm ore size, a preconcentration jigging circuit can be designed incorporating a proven, efficient recovery device for free gold: the InLine Pressure Jig....

Mine Tailings

Hazardous Properties. Toxic chemicals used to extract the valuable materials from the ore, such as the cyanide used in gold mining, remain in the tailings at the end of the process, and may leach out into ground water. Rock may naturally contain dangerous chemicals, such as arsenic and mercury, which leach into water much more readily after rock has been ground up and exposed to the wind and ......

Recovery of Gold, Silver, Palladium, and Copper from .

Electrorefining would be the most suitable for its high selectivity and controllability, especially with the advancement of EMEW technology. Since gold, silver, and palladium are available in low amounts, electrolysis is to be used for metal recovery due to its selectivity and ease of control....

Bacterial Leaching as a Pretreatment Step for Gold ...

Primarily, bioleaching with mixed acidophilic culture was applied as a pretreatment process for the recovery of nickel, cobalt, and zinc, as well as for iron removal....

Alfa Laval The brewery yield challenge: Making the most ...

The brewery yield challenge: Making the most of hops, cleaning and wort recovery Distinctively flavoured beers produced with dry hopping have become incredibly popular amongst consumers worldwide – from Europe and the Americas to Asia....

Estimated Water Requirements for Gold HeapLeach .

extracted. The barren solution is then reapplied to the top of the stack. Overall, gold recovery using heap leaching generally ranges from about 50 to 90 percent, although this percentage depends on many variables (Kappes, 2002; Marsden and House, 2006). Figure 1 is a simplified flow diagram of the gold heapleach process....

Leaching of a Gold Bearing Partially Roasted Sulphide ...

Thus, in view of the preliminary results of gold recovery by the cyanidation of the roasted product, and due to the existence in the plant of two gas fired furnaces, one rotary kiln and one hearth furnace, it was decided to proceed by developing a metallurgical route involving roasting prior to cyanidation. Selection of roasting conditions...

Dry Needling by a Physical Therapist: What You Should Know

Why Dry Needling? In cases when dry needling is used by physical therapists, it is typically 1 technique that's part of a larger treatment plan. Physical therapists use dry needling with the goal of releasing or inactivating trigger points to relieve pain or improve range of motion....

Consep Engineering Innovation

Consep Acacia. The Consep Acacia is a complete process solution to maximise recovery of gold from gravity concentrates such as those generated from a Knelson Concentrator. The Consep Acacia typically achieves overall recoveries in excess of 95%, often over 98%. Most importantly the Consep Acacia maintains an unblemished installation success rate....

Making Gold Green: New NonToxic Method for Mining Gold ...

May 14, 2013· This green method extracts gold from crude sources and leaves behind other metals that are often found mixed together with the crude gold. The new process also can be used to extract gold from consumer electronic waste. Current methods for gold recovery involve the use of highly poisonous cyanides, often leading to contamination of the environment....