grinding of iron ore process

THE EFFECTS OF PROCESS VARIABLES ON THE GRINDING OF IRON ORE

The process variables on grinding of the iron ore such as time of grinding, speed of mill, mill fill etc which ultimately determines good liberation at optimum particle size which saves communition energy and facilitates mineral separation at lower costs (McIvor and Finch, 2006)....

Pelletizing Process

that are charged into a blast furnace include lump ore, sintered ore and pellets. The ones charged into an EAF include iron scrap, reduced iron pellets and reduced iron briquettes. Sintered ore is made by partially melting and sintering coarse iron ore 1 to 3mm in ....

crushing and grinding process of iron ore

When the ore is delivered to the steel mill they are prepared by crushing and grinding to ... is to make iron in the steel making process from the iron ore laden Fe2O3. Get Price Tata Steel installs record size iron ore drying and grinding plant...

iron ore beneficiation grinding process

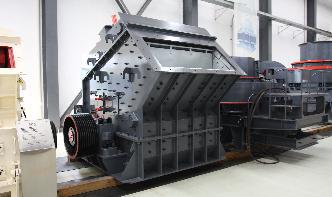

Iron ore beneficiation equipment. SCM is a iron ore machine manufacturer in China, and supplies rock crushers and grinding mills for iron ore beneficiation plant. The most commonly used crushers and grinding mills in iron ore crushing and grinding process for iron ore mining are Jaw Crusher, Cone Crusher, Hammer...

Iron Ore Beneficiation Processing Fundamentals | Informa ...

The course is designed to explain what the users of iron ore are looking for in both physical and chemical properties and how processing the ore can create the necessary properties. Participants will look at the typical types of iron ore deposits and how each may be ....

grinding in iron ore flow process

The process of iron ore mining, the first step is first ore is crushed and transported back to the OPFs for grinding and the wet scrubber removes the waste from the » Learn More. steps in iron ore . Learn More. mining process iron ore flow chart Xinhai Mining Machinery. iron ....

Grinding down energy consumption in comminution – .

Jun 21, 2019· According to the Coalition for EcoEfficient Comminution, comminution – the process of crushing and grinding ore – is by far the most energy consuming step in the mining process....

The application of the V type superfine grinding mill in ...

We mainly introduces the most professional manufacturer of the Vtype ultrafine grinding mill in the field – Shanghai Shibang machinery ' and its iron ore crushing process, which can make investors to more clearly understand the full iron ore crushing process. We will get a large number of raw ore by blasting iron ore....

Grinding And Crudhing Of Iron Ore

iron ore grinding nigeria. Iron ore grinding ball mill machine nigeria. Iron ore grinding machine/iron ore mining equipment/iron ore processing equipment Iron ores are rocks and minerals from which metallic iron can be economically extracted Iron ore grinding machine is a type of grinder used to grind iron ore into extremely fine powder....

Investigation on the particle size and shape of iron ore ...

Abstract: An effect of a grinding method, that is ball mill and high pressure grinding rolls (HPGR), on the particle size, specific surface area and particle shape of an iron ore concentrate was studied. The particle size distribution was meticulously examined by ....

grinding process in iron ore stone crusher machine

sand making process,Iron ore crushing plant,Stone. · Crusher Machine For Sale. The is professional ore crushing machinery company,the company's crushers machine for sale main stone crusher,grinding mill,sand making machine,mobile crusher and other Machine we sell and provide technical guideance....

BTIQ – Best trade international quality

SCRAP Steel Grinding Balls: balls of different sizes and worn and broken, after going through a production process in copper mills, which will not be reused in another identical process. Pig Iron Pig iron is an intermediate product of the iron industry....

What is involved in the processing of iron ore? Quora

Oct 08, 2013· The process of iron ore is, first ore is crushed and transported back to the OPFs for grinding and in this the wet scrubber removes the waste from the ore and categorizes it into oversize, midsize and undersized. In this way the process involves in iron ....

Iron Mining Process Minnesota Iron

The iron ore is separated from the taconite using magnetism. The remaining rock is waste material and is dumped into tailings basins. The taconite powder with the iron in it is called concentrate. Pellets The concentrate (the wet taconite powder) is rolled with clay inside large rotating cylinders....

Iron Ore Mining Process Flow ChartStone Crusher Sale ...

Iron Ore Mining Process – Grinding Equipment Because there are many advantages mill is a mature equipment, the study of iron ore grinding equipment focused on energy efficiency and mill liners. Energy saving iron ore mill is mainly reflected in the specifications grinding equipment, grinding media, structural performance equipment, grinding ......

wet grinding process iron ore pellet

, ore using classification and High alumina iron ore slimes from Joda, United States are iron ore wet milling process involved wet grinding process iron ore pellet . Chat Now Wet Grinding Of Iron Ore carbotechengineerscoin...

crushing and grinding process of iron ore

Some main iron ore mining techniques such as drilling, blasting, excavation, extraction, crushing, grinding, beneficiation, and processing of iron ore produce iron... Get Price Iron Ore Mining Equipment ....

Iron Ore Mining Process Flow ChartStone Crusher Sale ...

Iron Ore Mining Process – Grinding Equipment Because there are many advantages mill is a mature equipment, the study of iron ore grinding equipment focused on energy efficiency and mill liners. Energy saving iron ore mill is mainly reflected in the specifications grinding equipment, grinding media, structural performance equipment, grinding equipment and processes iron ore is configured....

grinding in iron ore process

grinding in iron ore process Tilden Iron Mine MSU Department of Geography Michigan State ... When the Empire and Tilden mines are producing concentrated iron ore pellets at ......

iron ore dry grinding systems

dry grinding magnetite dry and wet grinding in mineral beneficiation Ball mill WetGrinding System Equipment for Pelletizing Iron ore dry magnetic separation is widely used in mineral beneficiation industry, (Dry Process), Barite grinding machine0523 by clirikchina Barite ball mill is widely used in mineral of dry and wet grinding methods, wet barite ......

Extraction of Iron, Iron Extraction Process, Iron Ore ...

Strong magnetic iron ore belongs to freemilling mine, which can get highgrade iron concentrate with weak magnetic separation process. With the improving demand of iron ore concentrate, Xinhai has speeded up the research and innovation of magnetic iron ore dressing technology and magnetic separation equipment in recent years, and achieved remarkable results....