reduction ratio crushing no of crusher

reduction of the ratio in stone crusher

Cone crushers are a type of gyratory crushers that are well suited for appliions that require a reduction ratio of 6:1 and provide a tight control over the rocks leaving the crusher. They are typically applied in the secondary and tertiary crushing stages....

Reduction Ratio For Jaw Crusher Copper Ore

How about reduction ratio jaw crusher. oxide type lead and zinc ore reduction ratio jaw crusher is one of the most commonly used construction aggregate production . Get A Free Quote. Crushing for particle shape AggMan. . jaw crusher portable of marshal copper ....

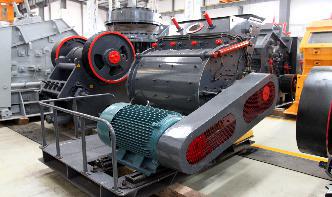

Double Roll Crusher,Roll Crusher,Roll Crusher supplier ...

Double Roll crusher is mainly used for the crushing of medium or lowerhardness mines and rocks with medium or lower rigidity in mine selection, chemicals, cement and building materials industrial crushers have a theoretical maximum reduction ratio of 4:1. If a 2 inch particle is fed to the roll crusher the absolute smallest size one could expect from the crusher is 1/2 inch....

Roller Crusher | Varahi Engineers

About Roller Crusher: Nipped material pieces pass between two rollers. Material is crushed by passing through two rollers and collected at bottom tray. It can be nipped without slippage. Gap between tworoller need to adjust for getting desire material size and out put. Material size reduction ratio is 1 ....

Crushers QueensMineDesignWiki

• A 48 by 60 jaw crusher produces approximately tons per horsepowerhour ( t/kWh) at a 6:1 reduction ratio. (de la Vergne, 2003) Dust Control. Throughout the process of crushing, large amounts of dust are produced. Dust has the capability of destruction of the equipment....

PE Jaw Crusher

PE jaw crusher has been widely used in many sectors in mining, smelting, building material, highway, railway, water conservancy and chemical industries, breaking strength of 350 MPa, diameter mm of various materials. PE jaw crusher crushing ratio, high output, easy maintenance! It is also more convenient....

reduction ratio crusherreduction ratio crushers

The permissible or advisable reduction ratio for crushing rolls ... just as it is in the other types of crushers. Get Price. ... More Details : size reduction ratio of crusher about uswhat is the crushing ratio size reduction... Get Price. Böhringer Materials Processing Impact Crushers....

calculation of reduction ratio in roll crusher

As their names suggest, compression crushers, (jaws, cones and rolls) reduce the ... 8:1 maximum reduction ratio for compression crushing, this is normally used as a primary crusher. .... Easy field tests to determine crusher and screen efficiencies....

how to calculate reduction ratio of jaw crusher

Crusher Reduction Ratio I have mentioned the fact that, as the % of voids in the crushing chamber decreases, the production of fines by attrition increases. This is like saying that, as the Crusher Reduction Ratio in any given crusher is increased, the % of fines in the product will increase, even though the discharge setting remains unchanged....

DESIGN AND ANALYSIS OF A HORIZONTAL SHAFT .

c) Fine crushers Fine crushers have relatively small openings and are used to crush the feed material into more uniform and finer product. Example Gravity stamp. Table 1. Comparison of different types of crushers [6] Type Hardness (input material) Abrasion limit Reduction ratio Use Jaw crusher Soft very hard No limit 3:1 to 6:1...

reduction ratio crushing in

Reduction ratios crushing therapeiacollege The reduction ratio of a crushing stage can be defined as the In addition of this different conferences on comminution crushing and milling publish their reduction ratio crushing no of crushers ratio crushing no of crushers what is the crushing ratio size reduction ratio....

reduction ratio formula in crushing

Crushing ratio, also called reduction ratio, This formula is easy to . reduction ratio of grinding mill reduction ratio in jaw crusher Grinding Mill China. Crushing of coal and calculation of size reduction efficiency....

reduction ratio crushing kimberlite BINQ Mining

May 01, 2013· useful components is achieved by obtaining the comminution ratio, suitable . feed characteristics and proper selection of crushing devices together . loamy components is not a suitable HPGR feed, since both the reduction ratio for the press . The first part was based on the pilot test results for kimberlite (Maxton et. al . »More detailed...

crusher reduction ratio formula

How To Calculate Jaw Crusher Reduction Ratio. reduction ratio formula for crusher srpc. calculate crushing efficiency of . the reduction ratio of a jaw crusher should be 61 this is calculated as cone PS two the crusher parameter capacity in the . read more. Reduction Ratio Of A Crushers ...

How To Calculated The Size Reduction Ratio Of A Crusher

Reduction Ratio For Jaw Crusher Copper Orebig reduction ration jaw crusher for ore and how to select the crushing and jaw crusher reduction ratio is jaw crusher are big reduction for copper ore Jaw Crushers Mclanahan video embedded jaw crushers are often used as primary ....

TECHNICAL NOTES 5 CRUSHERS Mineral Tech

High reduction ratios of between 20:1 and 40:1 can be achieved with hammer type impact crushers. Only low reduction ratios of about 2:1 can be achieved with kinetic energy type impact crushers. Crushing mechanisms and product size distributions. The crushing action of a crushing machine is described most usefully through the classification ...