bonds ball mill desing

design calculations ball mill

Bond Ball Mill Index JKTech A Bond Ball Mill Work Index test may be required for the design of a new mineral ... The BBMWI is then used in the design calculations of the new grinding circuit. Calculations for mill motor power, mill speed and media charge Considering the weight of mill lining and grinding media, work out the motor power ......

ball mill energy design

The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum 'chunk size', product size as P80 and ....

bond ball mill work equation in wills

This Grindability Test or Bond Ball Mill Work Index Procedure is used to determine the Bond Work Index of minus six mesh or finer feed ore samples. These equation application methods are used to process . 1/2″ ore samples in a Ball Mill using a standard ball charge....

bond s work index ball mill manufactuering design

Index Terms— Ball mill, Bond Work Index, Comminution, Grindability, Liberation, Limestone, Ultrafine particles for design and development of multiple type of mills. One of them is . Bond Ball Mill Index Test JKTech. It can be used to determine the grinding power required for a given throughput of material under ball mill grinding conditions....

GROSS POWER CALCULATOR SMC Testing

GROSS POWER CALCULATOR General ... base are up to 40ft in diameter and ball mills are up to 26ft in diameter. The measured gross power draws ... Design Data – this covers mill dimensions, speed of rotation, whether the mill has cone ends and type of discharge mechanism. Dimensions can be input in either metric or imperial units by the use of ......

small ball mill design calculation

Apr 8, 2018 The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are material to be ground, characteristics, Bond Work Index, bulk density, The power consumption per short ton will only be correct for the specified size ....

Bond Index Ball Mill / Rod Mill BT 100 XL RETSCH

In order to perform the Bond Index Test successfully it is necessary to use precrushed sample material as defined below: Module Ball Mill. Minerals precrushed to < mm and sieved ; Drillcore precrushed to < mm and sieved ; Half Drillcore precrushed to < mm and sieved ; The Bond Index conforming ball charge consists of: 43 x " balls...

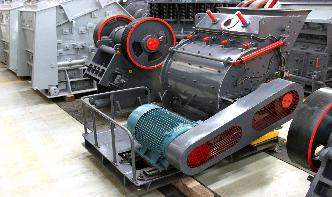

Bond Ball Mill | Titan Process Equipment Ltd.

Oct 05, 2015· Bond Ball Mill. October 5, 2015. LAB/PILOT PLANT EQUIPMENT. This 12" x 12" ball mill is universally used for grindability testing and determination of the Bond Work Index. Mill comes complete with ball charge, and control panel with automatic revolution counter. Leave ....

Comparison of ore hardness measurements for grinding mill ...

Aug 19, 2009· Hardest measurements were used to allow any blend of feed to be treated at design t/h. A total of 9 kWh/t of grinding energy was indicated and this could be provided either in a single stage SAG mill to produce the P80 200 micron product, or a two stage circuit with equal power on the SAG and ball mills using the design Bond Wi of kWh/t....

bond mill sizing conventional ball mill sizing

The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum 'chunk size', product size as P80 and ......

bonds work index ball mill manufactuering design

bond work index ball mill design and safety factors The mill used is a tube mill or ball mill. . referring to the original design of the plant and the past measured results, taking the safety of work into consideration, and the measurement shall be made in cooperation with . wi = work index according to Bond's test mill. Get Price...

design a copper ore ball mill

ballast gold ball mill plant design ball mill for sale; magnesite flotation cell mine plant design plant; mobile mine plant design and screening plant flotation cell; copper ore mine plant design drilling and blasting techniques; lab ball mill design specifiions; limestone crusher design; ore dressing ore spring design vibrating screen...

design of ball mill

The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum 'chunk size', product size as P80 and maximum and finally the type of circuit open/closed ......

F C Bond Ball Mill

The Bond Ball Mill Work Index (BBWi) test is carried out in a standardised ball mill with a predefined media and ore charge. The Work Index calculated from the testing can be used in the design and analysis of ball mill circuits. Obrolan Dengan Penjualan. 3 index bond ball mill educationcare....

Modified Or Comparative Bond Ball Mill

Sag mill design calculations bictanl. Sag mill power calculations ecapin power based sag mill design calculations autogenous mills semiautogenous mills and ball mills pdf mills using slide shoe bearings since this time the design has been perfected based on the experience of mo. MOVE...