how to improve the production of slag cement mill

how to set up a cement production plant

In order to increase cement production, Cherat Cement Company Limited is all set to set up a cement manufacturing plant in Nowshera at a cost of Rs 12 billion... Get Price PreFeasibility Report Sindh Board of Investment...

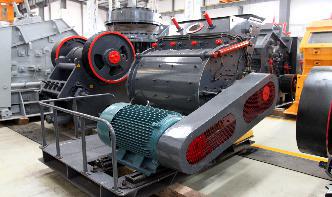

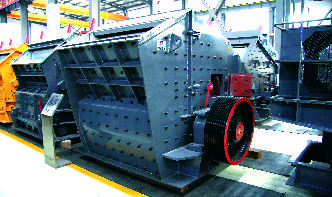

slag and cement refining and grinding machine

Our cement manufacturing process consists of many simultaneous and continuous operations using some of the largest moving machinery in manufacturing. ... of clinker; and (4) the grinding and blending of clinker to produce cement. ... cinder and slag to our crushing installations where they are refined to ....

slag ultra fine mill production plant

By continuing to browse the site, you are agreeing to our use of cookies. .... Ball Mill. Grinding and Drying Ball mill. The proven classical option for cement grinding. ... and reliable alternative for cement and granulated blast furnace slag grinding. ... separator, ball mills can reliably grind high grade and very fine cements. Get Price...

Loesche hands over world's largest slag mill – LM +3 ...

Oct 24, 2014· This was to be the largest slag mill in the world. ... the 2+2/3+3 system to improve grinding bed stability. ... sold throughout the world for the production of a wide spectrum of cement and slag ......

Slag powder production line Cement Equipment

Comprehensive performance of slag powder is widely used in the engineering construction, in the concrete configuration can replace 40 cement and concrete strength can reach above C60, can improve the concrete life, increase the strength and reduce the cost of the project; not only that, slag powder in cement enterprise production can be equivalent to replacing part of cement clinker dosage, greatly ....

Grinding Mill For Slag Powder Grinding

The company has built an annual output of 200,000 tons of slag powder production line. The mill is mainly made of mtm highpressure suspension roller mill. In the actual production process, the output is stable and the quality is stable. The technical indicators meet the design requirements. This paper introduces the production process....

Cement Production an overview | ScienceDirect Topics

The production of cement is either through the wet or dry process with the dry process as the preferred option because of the lower energy intensity. Cement production accounts for about 5% of total anthropogenic emissions (IFC, 2017). Cementbased structures constitute the largest surface area of all manmade structures (Odigure, 2009)....

how to improve production of cement mill

Generally speaking, there are three ways to improve the capacity of cement ball mill: a fine ball mill in front of cement ball mill grinding system better and improve the efficiency of grinding efficient energy saving ball mill Those ways, any of those can greatly improve the capacity of cement ball mill....

ball mill of slag granulation plant

slag granulation process pdf Primary Stone, Ball mill of slag granulation plant Posted at: October 10, 2013 LOESCHEMills for cement and granulated blast furnace s. USA Process for granulation of slag Google, Download PDF Info Publication, art by providing a novel and improved process for the granulation of molten slag wherein ......

Solid Waste Management in a Steel Plant – IspatGuru

Sep 29, 2014· Most of the BF liquid slag gets granulated and is sold to cement manufacturers for the manufacture of BF slag cement. A small amount of BF slag gets air cooled. The air cooled BF slag is either dumped as landfills or used in road repairs within the steel plant. In either case the iron contamination of the slag is separated and sold for remelting....

Cement Additives Division Improvement of cement ...

In this paper we describe in details an industrial test performed during the production of slag cement in a vertical mill, showing how the use of grinding aids can improve both process parameters and cement quality. The positive effects of chemical addition to particle size distribution and separator efficiency are discussed in details....

THE ESTIMATION OF SLAG PROPERTIES

THE ESTIMATION OF SLAG PROPERTIES Ken Mills Department of Materials, Imperial College, London, UK ... Slags are very important to the production of clean metals. ... and the slag composition shows a steady increase in CaO concentration and a decrease in Al2O3....

ZK slag by vertical mill enjoy 70% tax rebate with low ...

Henan Zhengzhou Machinery Co., Ltd. is a firstclass domestic industrial waste slag grinding system integrated supplier. There are incomparable advantages in the same industry on the side of slag ....

How Cement Mill Works

how to improve production of cement mill, How to improve ball mill output News CenterChina ..... and can reduce the temperature inside the mill, which is beneficial to the mill operation and improve ...When dry Ball mill works, capacity ......

The application of High costperformance ratio LM vertical ...

slag powder in concrete can play a good effect. LM vertical grinding mill with high cost performance ratio is the equipments that use for slag powder production, which has high efficient, low cost, complete functions, simple operation....

Cement mill

Cement ball mill is mainly used for circle flow grinding system, and it has the characteristics of high efficiency, big capacity, and low power consumption, especially for cement slag. Compared with traditional ball mills, it can increase 1520% of capacity and 10% of electricity, otherwise, the temperature of final products can lower than 2040℃, and the fineness of products is adjustable....

slag production and grinding

Slag Vertical Grinding Mill,Processing Production Line After slag vertical grinding mill slag can reach 250 mesh 350 mesh, is the quality of cement, concrete raw materials. "Vertical mill ....

GGBS Grinding Mill Drives Development of Cement and Brick ...

Because in our improvement work, slag through our research, can be processed by grinding into powder material, added into the production of cement to improve the cohesion, corrosion resistance, high temperature, frost and other properties. Thereby it enhances the strength of concrete, and thus improves the quality of our construction....

productivity increase of vertical roller mill for cement ...

FL wins cement plant order in Uruguay. ... technology including vertical roller mills for raw, coal and cement ... 253 vertical mill for cement grinding, ... Contact Supplier Productivity increase of the vertical roller mill for ......

New Concrete Production Craft Slag Instead of Cement ...

Slag can add up into concrete instead of equal cement to improve new mixed concrete working feature. According to different using requirements, slag powder can replace cement by 30/70%, and thus it can reduce cost by 1530 RMB per cubic meter of ....

Slag industry news from Global Slag

Dec 20, 2018· It produces cement products from ground granulated blastfurnace slag (GGBS). It says its GGBS cement has a carbon footprint of 32kg CO 2 /t compared to 850 900kg CO 2 /t for Ordinary Portland Cement (OPC). The Irish company operates four plants in Europe with a production ....