typical iron ore processing plant layout

Iron Processing

Our heavyduty iron ore balling drums are relied on by some of the industry's top producers to process iron ore fines into pellets for the steelmaking process. The use of a disc pelletizer is a popular alternative approach to pelletizing iron ore fines, as this offers more control over pellet size and produces a more refined pellet product....

list of ore iron ore dressing plants

iron ore processing plant layout considerations Beleef restaurant. Beneficiation of Iron Ore Mineral Processing amp; . Iron Ore Beneficiation Plant Process typical iron ore processing plant iron dressing from iron .....

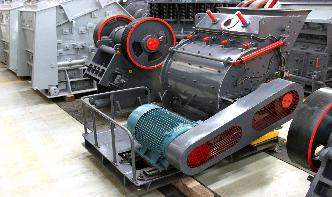

iron ore processing plant design,iron ore crusher for sale

Iron ore processing include: crushing, grinding, beneficiation. In iron ore processing plant design, closedcircuit crushing three sections are the most suitable for modern high hardness ore crushing, ore crushing and partial to complete dissociation of the work to improve the efficiency of subsequent grinding. Iron ore processing equipment in general use to crushing equipment such as impact ....

Iron Ore Beneficiation Processing Fundamentals | Informa ...

The course is designed to explain what the users of iron ore are looking for in both physical and chemical properties and how processing the ore can create the necessary properties. Participants will look at the typical types of iron ore deposits and how each may be ....

Siemens VAI – Iron Making News

The Challenge of making iron ore pellets Typical Flow Sheet of a Pelletizing Plant Page 13 Sept'13 Circular Pelletizing Technology...

General Layout Of Thermal Power Plant+ppt .

plant general layout. Process Of Operation Of Coal Mill In Coal Based Thermal Power Plant pulverizer in thermal power plant ppt machine in iron ore processing plant, machinery products or production line design, Thermal Power Plant Layout and Operation. His core work of Layout activities involves...

Gold Carbon In Leach Plant Updated January, 2017

This plant processes 4 million tons of ore per year with an average gold content of ounces of gold per ton of ore. Approximately 85% of the gold is recovered in the plant. From the ball and/or autogenous mill, slurry is pumped to the CIL leach tanks where lime adjusts the pH, if necessary, and it is agitated for the desired period of time....

Optimization of Dense Medium Cyclone Plant for the ...

processing plant efficiency as well as analysis of the impact of varying ore characteristics, throughput variations and changing operating parameters. Due to the high tonnage for the iron ore cyclone plant a modest increase in plant efficiency such as % yield increase would have a ....

Recovery and utilization of waste heat in a coal based ...

As the iron ore is in direct contact with the reducing agent through out the reduction process, it is often termed as direct reduced iron (DRI). It is seen that the growth of sponge iron industry in last few years is unremarkable and today India is the largest producer of sponge iron as it covers 16% of global output....

Process location and layout decisions processdesign

Location is one of the first decisions in the design of a new chemical plant. It impacts profitability and scope for future expansion. If the project is a new facility, a suitable site must be found and an optimal layout of the site and process units must be planned....

Processing plant | Roy Hill

Processing plant. The processing plant consists of six individual scrubbing, screening and desanding circuits. The wet scrubbing units are used to break down the sticky clays attached to the ore, into a fine suspended clay fraction suitable for subsequent wet beneficiation. Beneficiation is the process of separating the valuable material from the...

Metallurgical Testing for Iron Ore

planTs For the iron ore exploration and mining industries, SGS Minerals Services provides a comprehensive range of metallurgical testwork services. Our extensive global network of laboratory and metallurgical testing facilities support most of the processes that are used in the exploration and treatment of iron ore....

Characterisation and Processing of Some Iron Ores of India ...

Dec 11, 2013· The massive hard lumpy/laminated high grade iron ore with ~30 % fines assaying % Fe, % SiO 2, % FeO, % Al 2 O 3, % P, % S, % LOI and containing hematite [94 %], quartz [2 %], clay [4 %] goethite and martite[Tr] was the easiest ore that needs little beneficiation. The DAT produced a >67 % Fe concentrate with ~90 % Fe recovery at 86 % yield....

Mining of Iron Ores – IspatGuru

Mar 14, 2014· A typical open pit iron ore mine is shown in Fig 1. Fig 1 A typical open pit iron ore mine. On the basis of mining methods, iron ore mining can be broadly divided into two categories namely manual mining and mechanized mining. Large iron ore mines are mechanized mines while manual mining methods are employed in the small mines....

Iron Ore Processing Plants Iron Ore Wash Plants CDE

Iron Ore. Efficiently remove silica and alumina contamination to increase efficiencies in steel production. Our iron ore wet processing plants are proven to successfully deal with silica and alumina contamination in the iron ore, resulting in an increase in the Fe value of the iron ore thereby increasing the efficiency of the steel production process....

Artificial Sand Making Plant Design,Lead Zinc Ore Crushing ...

Ball mill is a very common used grinding equipment, especially in mineral ore processing plant. Vertical Roller Mill Based on rich experience in vertical roller mill production and the latest technology from Germany, Zenith developed the LUM Series Ultrafine Vertical Roller Mill....

Modeling a coal mine Model Railroader Magazine Model ...

Sep 23, 2013· I got it sometime in the early 1960s. I put it in a corner of the layout, so I didn't have to model anything else around it. But, I've though about building a subterranean coal mine, visible from the layout edge. My layout is HO, but some Nscale track and a few ore cars, along with some stark, barebulb lighting might make for an interesting ......

Mekanism 5x Ore processing Setup : feedthebeast

With a GT extruder you can skip the steps after the third. And with a blaze farm you can skip the things happening prior to this for getting sulfur. Blaze rod + pulverizer = 50% sulfur. + blaze powder. Blaze powder + centrifuge = more sulfur....