function of ball mill for cement production ppt

cement plants offered for sale | Mobile Crushers all over ...

Sep 28, 2015· cement plants offered for sale. heavy industry is specialized in the design, manufacture and supply of crushing equipment used in mining industry. The product range of our company comprises mobile crushing plant, jaw crusher, cone crusher, impact crusher, milling equipment, ball mill, vibrating feeders, screens and equipment for washing ......

How concrete is made material, manufacture, making, how ...

A ball mill is a rotating drum filled with steel balls of different sizes (depending on the desired fineness of the cement) that crush and grind the clinker. Gypsum is added during the grinding process....

PGNAA Improves Process and Quality Control in Cement ...

Cement producers who must meet increasingly stringent customer and regulatory requirements are turning to PGNAA cross belt analyzers for elemental composition data to improve quality control, process efficiency, energy savings and waste reduction. Cement raw materials must be carefully monitored and controlled to ensure the quality and conformity of the final product, concrete....

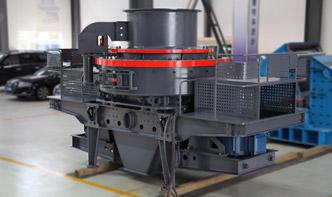

Vertical Roller Mill, Vertical Roller Mill Operation And ...

Vertical roller mill Introduction. The vertical roller mill which belongs to equipment for fine grinding, fine grinding of hard and medium hard or soft material in the building materials industry, especially used in the cement industry, ceramic industry, power sector, such as cement clinker, limestone, clay, China clay, feldspar, gypsum, barite and coal etc.....

Detail Views Of The Ball Mill

Ball Mill DesignPower Calculation. The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum 'chunk size', product size as P80 and....

Planetary Ball Mill PM 100 RETSCH highest fineness

Planetary Ball Mills are used wherever the highest degree of fineness is addition to wellproven mixing and size reduction processes, these mills also meet all technical requirements for colloidal grinding and provide the energy input necessary for mechanical extremely high centrifugal forces of a planetary ball mill result in very high pulverization energy and ......

"Improvement of mechanical strengths by the use of ...

Grinding aids in cement production The grinding process of cement absorbs 60 70 % of the total energy employed . Finish grinding accounts for about 38% of specif ic electric power consumption [2 ]. The quantity of energy req uired by the process to obtain the ....

objective of coal mill in cement plant

process of coal mill in cement plant . Ball Mill for Cement Plant in India,Cement Grinding Roller Ball Mill for Cement Plant feeder as per the raw mix mill system consists of a process flow diagram of the coal handling in Simulation of raw grinding system of a cement plant....

Horizontal mills for the cement industry

For ball mills in the cement industry, there are two fundamental choices that need to be made on the drive system. Will it be driven from a single drive system or dual, and will the selected drive system(s) be fixed or variable speed. Siemens, with its unique portfolio and ....

Application PLC in Cement and Steel Industry

Aug 19, 2010· PLC as a lower computer to control real device, such as batching system of raw materials, kiln of coal mill, ball milling, shaft kiln, etc. due to openness and performance price ratio, this kind of DCS is widely applied in middle and small process control system, subsystem of large process control system in cement factory....

Coal Mill |authorSTREAM

slide 3: 2. Pakistan 1000t/d cement plant purchased coal mill from CHAENG. 3. Φ×13m threebin high fine ball mill and coal mill are used in 1200t/d cement clinker production line in Xinjiang China and play extremely good production performance....

Feasibility of producing nano cement in a traditional ...

The mill can produce 25–130 t of cement per hour. According to the production plan, the mill will produce 100 t/h. Therefore, the daily production will reach 1,000 t, on assumption that the mill will run 10 h a day (based on the Alkufa factory work condition). Hence, the expected annual production of nano cement will be 300,000 t....

Selection of AC Induction Motors for Cement Plant .

In cement plants, proper specification and supply of AC induction motors is critical to project schedules and providing efficient production. This paper focuses on the selection of AC induction motors for cement mill applications, with reference to fan, kiln and vertical mill applications. The criteria for motor selection includes:...

CEMENT and CONCRETE TECHNOLOGY

to produce a given slump. They also provide a ball bearing effect, making the concrete easier to finish, and produce better cement hydration. By reducing the amount of water required, cement amounts can be reduced because concrete strength is directly related to ....

Teresa plant, the Philippines: cement grinding plant.

Whether considering raw meal grinding, cement grinding, or slag grinding, the FCB Horomill plant demonstrates the ability to operate at the lowest operating costs, while also maximising production. It offers the possibility to install one single type of mill in a complete plant with raw meal and cement being ground in identical mills, leading to...

Hammer Mill: components, operating principles, types, uses ...

Hammer Mill. It produces size reduction by impact. The materials to be milled are struck by these rectangular pieces of hardened steel (ganged hammer) which rotates at high speed inside the chamber. These radically swinging hammers (from the rotating central shaft) moves at a high angular velocity causing brittle fracture of the feed material....

Autogenous mills, semiautogenous mills and ball mills for ...

supported grinding mills up to the largest sizes. SAG/ball mill circuit incorporating pebble crushers and a POLYCOM® highpressure grinding roll. SAG and ball mill for gold ore grinding. One of three SAG mills with m diameter and 2 x 4000 kW drive power. These mills operate in conjunction with ball mills for iron ore grinding in Iran....

alignment ball mills polysius

5 tonne an hour ball mill; used ball mill for sale australia; size production ball mill; concrete crusher ball mill; ball mill detail free pdf; principle of a ball mill ppt; high energy ball mill; kurimoto ball mill manufacturer in america; whats the difference between a ball mill and roller mill; energy saving ball mill...

fl manufacturing of GGBS vertical roller mill goo ...

OPERATIONAL EXPERIENCE FROM THE UNITED STATES' FIRST VERTICAL ROLLER MILL FOR CEMENT GRINDING By: Mark Simmons Production Manager . ppt presentation on raw cement mill CGM Grinding Plant. ... Posts Related to cement grinding ball mill design in Sistan, Fars, Iran....

4 PRIMARY STEPS OF BRICK MANUFACTURING PROCESS .

After removing impurities it is exposed to weather for few months. This is called the process of weathering. After completion of weathering process the soil is blended with other material to prepare good brick earth. Then the mixed soil is tempered by being thoroughly broken up, watered and kneaded. The tempering is usually done in pug mill. 2....

INVESTIGATION ABOUT THE EFFECT OF CHEMICAL .

clinker conveyed in the grinding stage. Their macroscopic effect is the reduction of cement coating on grinding media and mill lining and the improvement of hourly mill production and cement fineness. Using a suitable grinding aid, it is possible to manufacture more cement at higher fineness, hence reducing the kWh/t....

The fineness and particle size distribution of ...

The fineness and particle size distribution of Portland cement. The final step in the production of cement is to grind the clinker pellets (and added gypsum) into a fine powder. The resulting individual cement particles have a variety of angular shapes, and a wide range of sizes (see Figure 37 below). Most of the cement particles will consist of regions of each of the four main cement minerals....

International Cement Review News, Events Training

the home of International Cement Review, the world's most requested magazine in the global cement industry. Leaders in News, Conferences, Training and Reports...

pdf for project commissioning erection of conveyors

Erection Free download as Powerpoint Presentation (.ppt), Text file (.txt), PDF File (.pdf) or view presentation slides online. ... Erection, Commissioning and performance ... » fls cement ball mill erection procedure download in pdf » how to select right ... Coal Conveyor Erection......

Raw Materials for Cement Manufacture

The first step in the manufacture of portland cement is to combine a variety of raw ingredients so that the resulting cement will have the desired chemical composition. These ingredients are ground into small particles to make them more reactive, blended together, and then the resulting raw mix is fed into a cement kiln which heats them to extremely high temperatures....