flotation of nickel

Flotation of sulphide minerals PDF Free Download

The effect of crystallochemical peculiarities of nickel sulphide minerals on flotation of copper–nickel ore The role of sodium sulphide in amine flotation of silicate zinc minerals Oxidation of sulphide minerals—I Potential control in the flotation of sulphide minerals and precious metals...

Nickel Ore processing Yantai Jinpeng Mining equipment ...

mixflotation the copper nickel from the ore, then separate the low grade nickel and low grade copper concentrate from the mix concentration . The nickel concentrate after smelting obtain the highgrade nickel matte, then use floation to separate the highgrade nickel matte ....

Introduction to Mineral Processing

Lead/Zinc Ore. The main difference in lead/zinc flotation is that zinc is usually depressed while lead (and copper) is floated. The tailing from the lead flotation circuit is the feed to the zinc circuit. The ability to selectively float the separate minerals depends on the ore, the chemicals, and other factors....

The effect of a novel depressant on the separation of talc ...

carboxymethyl cellulose (CMC) in the flotation of copper–nickel minerals from a lowgrade Cu/Ni sulfide ore which contains talc, in the Tianlong Copper–nickel Mine. In addition, the adsorption mechanisms of SAG on chalcopyrite and talc were investigated by contact angle tests and zeta potential measurements as well as infrared spectrum analysis....

USB1 Arsenide depression in flotation of multi ...

In step 160, the combination of the scavenger and magnetic concentrates is reground. Cleaner flotation produces cleaner concentrate and pyrrhotite tails in step 170. Finally, in step 180, the rougher concentrate and cleaner concentrate are combined as final copper nickel bulk concentrate....

Chapter 16: Flotation of Nickel and Nickel Copper Ores ...

Chapter 16: Flotation of Nickel and Nickel Copper Ores ORE TYPES AND MINERALOGY There are more than 45 different nickel minerals, but only a few are of economic importance....

CHAPTER 3 COMPARISON OF DIFFERENT PYRRHOTITE .

pyrrhotite collectorless flotation, it is difficult to achieve a clean separation between pentlandite and pyrrhotite. Pyrrhotite rejections has been a longstanding problem in the nickel industry. Nickel producers have been using a number of different strategies, sometimes in combination, to ....

Introduction to Mineral Processing

Lead/Zinc Ore. The main difference in lead/zinc flotation is that zinc is usually depressed while lead (and copper) is floated. The tailing from the lead flotation circuit is the feed to the zinc circuit. The ability to selectively float the separate minerals depends on the ore, the chemicals, and other factors....

flotation of oxides of copper and nickel

The choice of frother in the bulk flotation of a nickel ore also depends on the occurrence and nature of the ore as well as on the gangue slime present....

1 Froth Flotation – Fundamental Principles

Froth flotation is a highly versatile method for physically separating particles based on differences in the ability of air bubbles to selectively adhere to specific mineral surfaces in a mineral/water slurry....

Flotation Of Copper Nickel

Flotation of NickelCopper Sulphide Ore: Optimisation . the major challenges faced by flotation of these ores is the ever varying grade and mineralogy. This therefore calls for a continual characterisation and optimisation of flotation parameters such that concentrator ....

Nickel: smelting, producingMetalpedia

International Nickel (INCO) and Sherritt Gordon use a bulk Cu/Ni float pictured below, followed by selective flotation of the two elements into separate concentrates. Other Canadian producers leave separation to the smelters....

An Approach to the Flotation of Western Australian Nickel ...

Recent exploration has established depos its of nickel sulphide in several areas of Western Australia. To assist in their develop ment Amdel has investigated the beneficiation of many samples from these deposits and has estab lished flowsheets for the recovery of nickel values by flotation....

froth flotation process for nickel

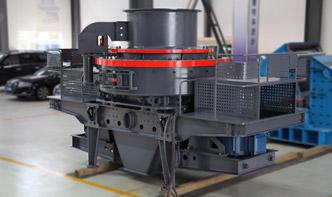

copper nickel ore flotation equipment nickel and molybdenumCopper ore flotation equipment The flotation process mining machine has the froth flotation method copper mining sand washing machine with a copper grade of 145% in a singlestage froth flotation Frash process a solution mining method operated at an elevated Read more...

Development of a Combined Flotation and High Pressure ...

Flotation behavior of copper and nickel as a function of collector dosage (Flotation conditions: 10% pulp density, pH 5, and flotation time of 10 minutes). tite ( ) because the grade and recovery of iron increased with increasing of PAX dosage [15] [16] [17] ....

Nickel: Extraction and purification

Apr 24, 2010· In many stainless steel applications, 75% pure nickel can be used without further purification depending on the composition of the impurities. Nickel sulfide ores undergo flotation (differential flotation if Ni/Fe ratio is too low) and then are smelted. After producing the nickel matte, further processing is done via the SherrittGordon process....

A New Process for Cobalt Nickel Separation

This combination of flotation and smelting effectively removes most of the deleterious impurities, and thus produces a nickelcobalt matte suitable for leaching and eventual Cyanex 272 separation of nickel and cobalt. Historically of course almost all nickel sulphide ores have been treated in this way; however, not all sulphide ores...

Flotation collectors | Solvay

AEROPHINE®, AERO® and AEROFLOAT® collectors (promoters) are used extensively for the flotation of sulfide minerals including copper, gold, lead, zinc, nickel, iron and many others that provide improved performance and higher selectivity than more traditional sulfide collectors and better overall metallurgical performance....

FROTH FLOTATION : RECENT TRENDS Flotation of .

Flotation is a method of separating an ore species froth another, based on its hydrophobic surface characteristics either natural or induced when present as a suspension in water with air bubble....

flotation of nickel ores pdf

nickel ore flotation beneficiation plant. In this paper, an alternative beneficiation process to recover nickel The focus of this study was the concentration of the nickel ores by flotation in columns, with the nickel concentrate that would be fed into the nickel matte production plant. Get Price...

Flotation Reagents Collectors | ArrMaz

Flotation Reagents Collectors. Froth flotation is the most widely used industrial process for the separation of finely liberated minerals. The process involves the aeration of minerals in water in the presence of flotation reagents which facilitate the attachment of ....

(PDF) Sulphidization to improve the nickel oxide recovery ...

Increasing the time of sulphidization (> 5 min) decreased nickel oxide recovery. Flotation at Eh of –450 mV SHE produced the maximum recovery of 63%, from 37% without sulphidization (2x104 M PAX)....

The flotation of gersdorffite in sulphide nickel systems ...

TSS has been reported to be an effective and nickel concentrates containing high levels of arsenic can therefore depressant for pyrrhotite in copper–nickel sulphide systems (Xu et al., sometimes be difficult to market (Toguri, Babaie and Sridhar, 1995)....

Flotation | ore dressing |

Flotation. Flotation is widely used to concentrate copper, lead, and zinc minerals, which commonly accompany one another in their ores. Many complex ore mixtures formerly of little value have become major sources of certain metals by means of the flotation process....