common iron ores with their properties grinding mill china

Creating Iron | HowStuffWorks

The more advanced way to smelt iron is in a blast furnace. A blast furnace is charged with iron ore, charcoal or coke (coke is charcoal made from coal) and limestone (CaCO 3 ). Huge quantities of air blast in at the bottom of the furnace, and the calcium in the limestone combines with the silicates to ....

Magnetite Lodestone | Mineral Photos, Uses, Properties

Use of Magnetite as an Ore of Iron. Most of the iron ore mined today is a banded sedimentary rock known as taconite that contains a mixture of magnetite, hematite, and chert. Once considered a waste material, taconite became an important ore after higher grade deposits were depleted. Today's commercial taconites contain 25 to 30% iron by weight....

List of Ores of Metals – Winentrance

Nov 02, 2010· List of Ores of Metals SubjectNo. of SeatsSubjectNo. of Seats Diploma in Clinical Pathology (DCP)03Diploma in Anaesthesiology (DA)03 Diploma in Radio List of Ores of Metals Ores Chemical Formulae Aluminium Iron Copper Zinc Potassium Silver Calcium...

Ores / Minerals / Metals NETZSCH Grinding Dispersing

Metals and their alloys are almost as old as the history of mankind and have had a lasting effect on our culture. For this reason, certain periods in the history of mankind have been named after the materials used, such as the Bronze Age or the Iron Age....

Steel Wikipedia

It is the interaction of the allotropes of iron with the alloying elements, primarily carbon, that gives steel and cast iron their range of unique properties. In pure iron, the crystal structure has relatively little resistance to the iron atoms slipping past one another, and so pure iron is quite ductile, ....

The Making of Iron Steel SEAISI

Iron ore, as mined, is a combination of iron with oxygen and various other unwanted substances, generally known as "gangue". The first metallurgical step is to reduce iron ore to metallic iron, a process which is mostly carried out in a blast furnace, using coke as both a fuel and reducing agent....

How iron is made material, manufacture, making, history ...

The raw materials used to produce pig iron in a blast furnace are iron ore, coke, sinter, and limestone. Iron ores are mainly iron oxides and include magnetite, hematite, limonite, and many other rocks. The iron content of these ores ranges from 70% down to 20% or less....

Utilization of Iron Ore Tailings as Raw Material for ...

Clay was from a brick plant in Shiyan and iron ore was from Jiugang Group. Limestone and quartz sand were acquired from Huangshi XinHai Trade Co., Ltd., and Jingyou Sand Co., Ltd., respectively. IOT, clay, limestone, quartz sand, and iron ore were used as ....

Rcovery of gold in pyritic ores

Using cyanide to recover gold from sulfide ores generally results in 30 to 35% recovery, and the best I have heard of is around 50% recovery. The fine coating of a iron compound definitely appears to be a key component of the inability of cyanide to efficiently leach low grade pyritic ores....

Industries :: Mining :: Industry Subsectors

Description: This industry comprises establishments primarily engaged in (1) developing mine sites, mining, and/or beneficiating (, preparing) iron ores and manganiferous ores valued chiefly for their iron content and/or (2) producing sinter iron ore (except iron ore produced in iron and steel mills) and other iron ore agglomerates....

Power Transmission Products Solutions for Iron Ore .

Iron is one of the most common elements on Earth, comprising about five percent of the Earth's crust. To extract and process iron ore from beneath the surface rock efficiently every day, it requires an orchestrated operating process. From crushing and grinding to pelletizing and stockpiling, you...

Energy Use of Fine Grinding in Mineral Processing ...

Dec 18, 2013· F ine grinding is becoming an increasingly common unit operation in mineral processing. While fine grinding can liberate ores that would otherwise be considered untreatable, it can entail high costs in terms of energy consumption and media use. These costs can be minimized by performing adequate test work and selecting appropriate operating ......

Michigan Iron Mines

Michigan iron ore averages about 51 per cent iron natural. Its parent rock, the iron formation, averages 20 per cent to 25 per cent iron. The ore is a product of a natural concentration of the iron by removal of its associated silica Ore is not found everywhere in the parent material. It represents less than one per cent of the total volume of...

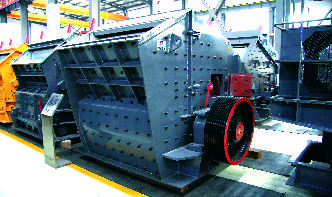

European Ball Mill Iron Ore

european ball mill iron ore . european ball mill iron ore Iron ore beneficiation equipment SAM is a iron ore machine manufacturer in China, and supplies rock crushers and grinding mills for iron ore beneficiation plant. The most commonly used crushers and grinding mills in iron ore crushing and grinding process for iron ......

How is iron ore priced? | Financial Times

Mar 09, 2016· So how is the current iron ore price worked out? From April 2010 miners moved their steel mill clients on to shorter indexlinked contracts. Initially based on quarterly prices, China ....

A Methodology to Estimate Ores Work Index Values, .

common methods applied for ores is standard Bond Ball Mill method[1]. This Bond Ball Mill is 12 inches 12× (diameter×length) which uses 20125g of...

How is Steel Produced? | World Coal Association

Iron ore is mined in around 50 countries – the largest producers are Australia, Brazil and China. Around 98% of iron ore is used in steelmaking. During the ironmaking process, a blast furnace is fed with the iron ore, coke and small quantities of fluxes (minerals, ....

Innovations: Introduction to Copper: Mining Extraction

Copper Applications in Metallurgy of Copper Copper Alloys. Such ores are called porphyries. Where mineralized rocks become outcropped or shattered, the sulfide minerals undergo chemical changes due to air, groundwater and heat, giving rise to the other main variety of copper minerals the oxidized ores....

(PDF) Life cycle assessment of iron ore mining and processing

Life cycle assessment of iron ore mining and processing 619. Many minerals contain iron, but the primary sources of iron ore minerals used to. make iron and steel are hematite, magnetite, goethite, siderite, and pyrite....

Ferrous metallurgy Wikipedia

Ferrous metallurgy. It is not known when or where the smelting of iron from ores began, but by the end of the 2nd millennium BC iron was being produced from iron ores from SubSaharan Africa to China. The use of wrought iron (worked iron) was known by the 1st ....

Chapter 1 Introduction to Types and Identification of Metal

the mined iron ore is used to make steel. Iron is produced by converting iron ore to pig iron using a blast furnace. Pig iron is the intermediate product of smelting iron ore with coke, usually with limestone as a flux. Pig iron has very high carbon content, typically –%, which makes it very brittle and not useful directly as a material ......