use of water in vertical roller cement mill

gypsum dehydration in vertical cement mill | Solution for ...

Mar 19, 2013· Cement grinding process,Vertical roller mills and ball mills . This means that a lower degree of dehydration of the gypsum must be . dehydration of the gypsum also when grinding cement in a vertical roller mill, . gypsum dehydration during comminution and its effect on cement . effect of cement mill temperature on cement properties....

Analysis of the various types of mills 2 Appropedia: The ...

There are several types of motorisation available, each corresponding to a different type of mill: manual mill, animal traction, motor and even water. A. Principle of operation The principle of operation of these mills are the grinding of the grain by crushing it between two abrasive surfaces: the wheels....

History and Technology of Watermills Jesmond Dene Old Mill

Water mills use the flow of water to turn a large waterwheel. A shaft connected to the wheel axle is then used to transmit the power from the water through a system of gears and cogs to work machinery, such as a millstone to grind corn....

Rolling Mill Guide Equipments – IspatGuru

Jul 20, 2015· In modern roller guides, drop forged roller holders in spring steel quality, are used which enables thicker front and tail ends to pass through the guide without disturbing the original setting of the roller guide. The design of roller guides has undergone big changes with the introduction of faster continuous rolling mills....

Loesche vertical roller mill for use in a cement plant in ...

Loesche has now been able to provide a vertical roller mill of type LM +3 CS for grinding cement clinker to its end customer Attock Cement Pakistan Limited (ACPL). The new mill will be used in the new line 3 of the cement plant in Hub Chowki in Pakistan, in ....

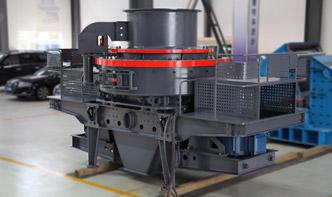

Cement Vertical Mill

The cement vertical roller mill is one of the most important cement equipment. It is the key grinding machine of materials being crushed. The cement grinding mill plays a vital role in cement production line and cement production process ....

Roller Mill Maintenance00

Roller Mill Maintenance Roller mills are used around the feed mill to perform a variety of tasks. Applications include crumbling pellets, cracking corn, dry rolling and steam flaking grain, and grinding corn, wheat, or milo for mash and pelleted feeds. While each application has some unique...

AVAILABLE AND EMERGING TECHNOLOGIES FOR .

Cement is a finely ground powder which, when mixed with water, forms a hardening paste of calcium silicate hydrates and calcium aluminate hydrates. Cement is used in mortar (to bind together bricks or stones) and concrete (bulk rocklike building material made from cement, aggregate, sand, and water)....

grinding mill in cement industry,grinding machine manufacturer

In our country, the promotion and use of vertical grinding mill seems a bit slow. Due to the use of habit, ball mill, roller press as the traditional ball mill grinding equipment, which has more than 100 years of history, especially the low cost, the ball mill cement sphericity Gauguin is let very favour of cement ....

The cement mill

Cement manufacturing brief description of a cement mill. Cement clinker is usually ground using a ball mill. This is essentially a large rotating drum containing grinding media normally steel balls. As the drum rotates, the motion of the balls crushes the clinker. The drum rotates approximately once every couple of seconds....

Cement Additives Division Improvement of cement ...

Cement Additives Division Improvement of cement performances through the use of grinding aids in vertical roller mill 'Arcangelo, – Mapei SpA, Milan, Italy Abstract Due to the stringent requirement of energy saving, the use of vertical roller mills for cement grinding is now common....

Globally established LOESCHE vertical roller mill for use ...

Jul 26, 2017· LOESCHE has now been able to provide a vertical roller mill of type LM +3 CS for grinding cement clinker to its end customer Attock Cement Pakistan Limited (ACPL). The ....

production of cement grinding mill grinding mill

Vertical grinding mill for water slag processing cement production. Get Price. Vertical roller mill for cement grinding. In the cement grinding process, grinding system using the tube mill is widely applied for ... grinding and vertical mill technologies used in cement manufacturing. ......

FAG Rolling Bearings in Rolling Mills

In strip mills, in finesection and wire mills, the rolling speeds are so high in many cases that it is no longer possible to use axial tapered roller bearings and axial spherical roller bearings. The axial bearings used in these cases are angular contact ball bearings or deep groove ball bearings....

Loesche vertical roller mill for use in a cement plant in ...

Loesche has now been able to provide a vertical roller mill of type LM +3 CS for grinding cement clinker to its end customer Attock Cement Pakistan Limited (ACPL). The new mill will be used in the new line 3 of the cement plant in Hub Chowki in Pakistan, in the Lasbela/Baluchistan district, 20 km north of Karachi....

water the best grinding aid for vertical cement mill

Cement Additives Division 1 Improvement of cement performances through the use of grinding aids in vertical roller mill 'Arcangelo, – Mapei SpA, Milan, Italy Abstract Due to the stringent requirement of energy saving, the use of vertical roller mills for cement grinding is now common....

Grinding Mill In Cement Industry, Grinding Machine ...

In order to better study the cement vertical mill, ball mill, roller press in the application of the domestic actual situation, some industry experts for the comparative study of the many several grinding equipment, the final result, cement vertical mill finish grinding in power consumption, investment, product performance and other aspects is ......

Vertical Cement Mill CHAENG

Cement ball mill; Ball Mill; Coal vertical roller mill; Raw Material Vertical Mill; Slag Vertical Roller Mill; Vertical Cement Mill; Crushing. Jaw crusher; Hammer ....

process of cement milling

Concrete is formed when portland cement creates a paste with water that binds with sand and rock to harden. Cement is manufactured through a closely controlled chemical combination of calcium, silicon, aluminum, iron and other ingredients. ... cement manufacturing technologies. 3-3b c2 vertical roller mill cement manufacturing material ......

ROLLERCOMPACTED CONCRETE

ROLLERCOMPACTED CONCRETE RCC consists of portland cement, coarse and fi ne aggregates, and water. RCC requires no forms, fi nishing, steel reinforcement or joint sawing. However, sawcut joints can be easily created to offer an enhanced appearance and to help control cracking. The Process RCC takes its name from the method used to build it....

Cement vertical roller mill finish grinding technology ...

Apr 09, 2015· Cement vertical roller mill finish grinding technology research and Application As is known to all, the power consumption of cement grinding system for cement plant in the total power consumption of 68%, so to reduce the power consumption of grinding system is one of the most important aspects to reduce the total energy consumption of cement ......

Cement Milling Understanding Cement

Vertical roller mills (VRMs) are the main alternative means of grinding the clinker and are increasingly being used. For a quick introduction to VRMs see, for example, this advertisement on Youtube for an FL VRM. As part of the grinding process, calcium sulfate is added as a set regulator, usually in the form of gypsum (CaSO 2 O)....

Cement Process Energy Saving ECCJ

mill by vertical roller mill 3)Pneumatic transfer of raw material to mechanical transfer Third step 1)Installation of closed circuit mill (separator) 2)Installation of feed control system 1)Use of industrial waste (waste tire, etc) 2)Heat recovery of preheater exhaust gas and cooler exhaust gas (drying of raw material and generation of...