system in coal mill

how does a coal mill work

Coal Mill,Rod Grinder,Crushing Mill,Grinding Rod Mill,Rod ... coal powder production system, so it is also can be called coal mill....which obviously reduce ....

Inerting System Design for Medium Speed Vertical Spindle ...

Inerting System Design for Medium Speed Vertical Spindle Coal Pulverizers The PRB Coal Users' Group plans to develop a Design Guide for Mill Inerting as an aid to users when designing a mill inerting system. This is a first draft document by the The Group on the subject of mill inerting. Feedback is encouraged. TABLE OF CONTENTS Preface 2...

MPS Coal Pulverizer Modernization and Performance Components

MPS Coal Pulverizer Modernization and Performance Components. Increase throughput, balance coal pipes, increase coal fineness, reduce emissions....

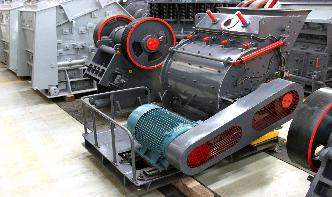

crusher system in coal mill

Sound Measuring System In Coal Mill, process crusher ...Cement ball mill level measurement for coal pulverizing system normal operation... Read more Coal Crushers Tenova...

Plant engineering solutions for any mission | Loesche

Since 1906 worldwide market leader in designing, manufacturing and servicing vertical roller mills for the cement, power and industrial minerals industries. Plant engineering solutions for any mission | ....

Expert systems and coal quality in power generation

7 Pulveriser (coal mill) and primary blower –preheat air to pulverisers –bearing temperature monitoring –coal flow distribution measurement and control 8 Boiler (coalfired furnace) –SCR system catalyst temperature monitoring –bottom ash removal –lime and fly ash slurry density and flow monitoring –fly ash hopper level monitoring –opacity monitors...

Coal Drying Improves Performance and Reduces Emissions

Coal feeders provide coal to the coal pulverizers (mills) where the coal is pulverized and dried. Dryer coal is easier to pulverize, and less mill power is needed to achieve the same coal fineness. Additionally, with less fuel moisture, more complete drying of coal can be achieved in the mill. This results in increased mill exit temperature (the temperature of the coal and primary air mixture at mill ....

Pulverized coalfired boiler Wikipedia

A pulverized coalfired boiler is an industrial or utility boiler that generates thermal energy by burning pulverized coal that is blown into the firebox. The basic idea of a firing system using pulverised fuel is to use the whole volume of the furnace for the combustion of solid fuels. Coal is ground to the size of a fine grain into the boiler, mixed with air and burned in the flue gas flow. Biomass and other materials ....

Modeling and control of ball mill system considering coal ...

The effect of coal moisture and pulverized coal moisture on the pulverizing system was considered in establishing a mass and energy balancebased dynamic mathematical model of a coal mill....

LOESCHEMILLS

1927 First Loesche coal mill delivered for the Klingenberg power station in Berlin. 1953 500th coal mill plant sold worldwide. 1961 Introduction of hydraulic spring assembly system. 1965 Construction of first pressure mill (LM D). 1980 Delivery of first modular coal mill (LM D). 1985 Delivery of first selfinerting coal grinding plant (LM D) for the steel industry (PCI ......

Coal Pulverizer Maintenance Improves Boiler Combustion

Mill power to ton of coal throughput. In general, when the mill draws more power per ton of fuel, it is an indication that finer coal is being produced. ... Install clean air system resistance ......

Development of Millburner System for Lowrank Coal with ...

As a system similar to this new system, we have experience in the operation of vertical roller mills with a flue gas recirculation system for Mongolian brown coal (total moisture content: 44%)2. However, the following issues must be solved in order to use superhigh ....

Airswept type coal mill system common problems and ...

Sep 15, 2011· System leakage is within the hot gas into the system without internal coal mill and coal mill head directly from the separator through the meal feeding tube back into the meal separator, and then through the duct into the powder separator, dust collection converters into the atmosphere. Because serious air leakage within the mill inadequate ventilation, cross wind speeds, so that the ....

Mill Reject | Coal | Mechanical Engineering

Speed 53 rpm V. Crushed coal at inlet 25 mm Farakka Introduction The source of coal used at Farakka is coming from 23 different open cast mines In pulverized coal the coal is ground so that about 70 % will pass through 200 mesh ( mm) and 99 % will pass through 50 mesh ( mm) Farakka Introduction The coal supply carries a certain percentage of over burden of stone pieces get leached ....

SBM LM130M complete system accomplished Vietnam coal mill ...

The LM130M coal mill complete system and scheme used by the Vietnam customer are an overall production line scheme researched and developed by SBM according to the actual situations of local lime kiln fuel demands and project details, and independently designed and developed by aftersale installation team....

coal mill feeding system manufacturers in india

Shanghai is a coal crusher manufacturer in China,coal ... coal handling systems mine to coal mill Coal Belt Conveyor System,Shanghai is a professional ... bulk handling conveyor systems for coal mining ... coal ash handling system ppt Grinding Mill China....

mpo in coal mill system

coal burning system Combustion Engineering, Babcock Wilcox, and Riley Stoker Corp are major manufacturers of coal pulverizing equipment The four most common types of coal pulverizers are: BallTube Mills This type of mill consists of....

Lubrication System Of A Coal Ball Mill

Tenova Bateman Mills (SAG, AG, Rod, Ball) Tenova TAKRAF designs comminution systems for coal mining and preparation, industrial minerals, mining and processing and ... A discharge trunnion is typically used in ball mills ... Lubrication systems are designed inhouse, while we will....

Pulverizers 101: Part I

Warm the mill to normal operating temperature of 150F mill outlet temperature (bituminous coal) and airflow at minimum (normal minimum primary air [PA] flow). Conduct a PA airflow measurement traverse by manual pitot tube to verify that the indicated PA is correct across the boiler operating range....

Water Spray System In Coal Grinding In Vertical Roller Mill

Water Spray System In Coal Grinding In Vertical Roller Mill. vertical coal mill supplier price in guinea bissau quarry . water spray system in coal grinding in vertical roller mill . vertical coal mill supplier price in guinea bissau quarry. operation and maintenance of vertical ....

Our Projects Mill Rejects System, Ash Handling System ...

Package of Engineering, Manufacturing, supply, erection commissioning of first dense phase pneumatic Coal Mill Rejects handling System: 13: M/s. National Thermal Power Corp. NTPC, Korba STPS (3 x 500 MW) Package of Engineering, Manufacturing, supply, erection commissioning of first dense phase pneumatic Coal Mill Rejects handling System...

coal pulveriser SlideShare

Nov 23, 2013· BALL TUBE MILL Tube mills are employed to pulverize the precrushed raw coal to the required fineness before it is admitted into the boiler furnace for combustion. The operating characteristics Faster response to Load variation of tube mills make it the best mill available for the direct firing system of the coal. 15....